With extreme weather events increasing in frequency and intensity, climate change is a key consideration when planning projects. Designers are increasingly looking into design efficiencies and product innovations to decrease carbon emissions while simultaneously catering to, and protecting against, the affects these events have on their projects.

Recycled materials

New Zealand recycles 45,000 tonnes of plastic each year. Of this, 55% comes from household sources collected through kerbside waste services.

Household waste often consists of single use plastic packaging, the greatest proportion of the plastic industry's greenhouse gas emissions can be attributed to the supply of raw materials for these single use items. By recycling and reusing single use plastic, such as Polypropylene (PP), it’s possible to greatly reduce the carbon footprint of products while repurposing waste that would otherwise be sent to landfill.

Allproof manufactures a wide range of drainage and passive fire protection products from 100% recycled PP, preventing over 12 tonnes — the equivalent of more than 383,500 takeaway containers — from going to landfill every month.

Clean energy

Allproof utilises clean energy generated on site through 449 solar panels installed on the roof of the main production facility. The solar installation generates a daily average of 750kWh of clean renewable energy (more than 1,000kWh per day during summer months) providing 50% of the building’s energy needs. To provide context, this is enough power to supply approximately 34 average New Zealand homes.

The installation of solar panels on Allproof’s main facility saves 50 tonnes of CO2 from entering the atmosphere every year, thus removing this from the embodied carbon of products during the production process.

Using local suppliers

Embodied carbon through logistics and installation can be reduced by selecting local manufacturers who supply innovative solutions designed specifically for the New Zealand market reducing transportation.

Allproof’s manufacturing facility is located on the North Shore of Auckland and sources locally available materials where possible, such as the 100% recycled polypropylene mentioned above which is from an Auckland based recycling and processing plant.

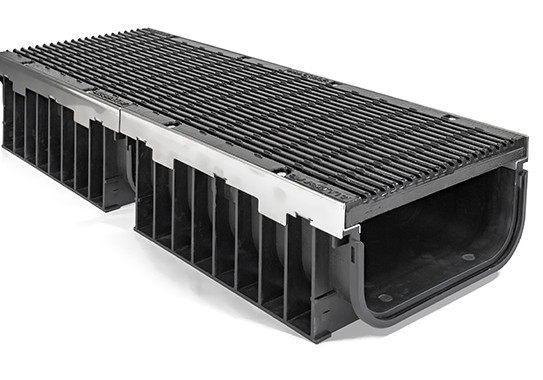

Allproof manufacture drainage solutions with consideration to the installation process, such as the Commercial Channel. The latest addition to the range is the 300mm wide channel drain, made in New Zealand from 100% recycled material using solar energy. The material makes it a durable lightweight solution reducing embodied carbon during logistics to site. The 150mm depth provides a high performing system allowing for a 200mm outlet, while minimising excavation and associated carbon.

When specifying products, it’s important to consider suppliers that are taking tangible and honest steps towards carbon reduction rather than utilising schemes that offset carbon rather than reduce it. Selecting local manufacturers who have sustainability set as a core value, evident by using recycled material, zero waste and on-site recycling schemes, clean energy production and electric and hybrid vehicles/equipment, provides New Zealand projects with premium and environmentally conscious solutions.

New Products

New Products

Popular Products from Allproof Industries

Popular Products from Allproof Industries

Posts by Andrew Smith

Posts by Andrew Smith

Most Popular

Most Popular