The success of an architecturally designed project can be measured on the accuracy of achieving specific details as per the design intention. Projects may call for drainage systems that follow the unique profile of the building envelope, protecting it and occupants from surface water.

Auckland’s Horizon Hotel’s main entrances are revolving doors with level entry access which required curved drainage channels to follow the joinery profile. Allproof collaborated with Warren Mahoney and Moller Architects to deliver a bespoke drainage solution for these entrances.

The design required a custom-made drainage system to the radius and widths of the revolving doors. Allproof was able to accommodate this through their custom manufacturing service, while leaning on knowledge and experience to ensure compliance with all NZBC clauses and AS/NZS standards.

NZBC E2 sets out strict criteria for level threshold drainage solutions. Channels must be a minimum 150mm (D) x 200mm (W) with a 1:200 fall across the base of the channel to an outlet located no further than every 3.7 metres. Grates must be removable and independently supported with a 12mm separation from the door joinery.

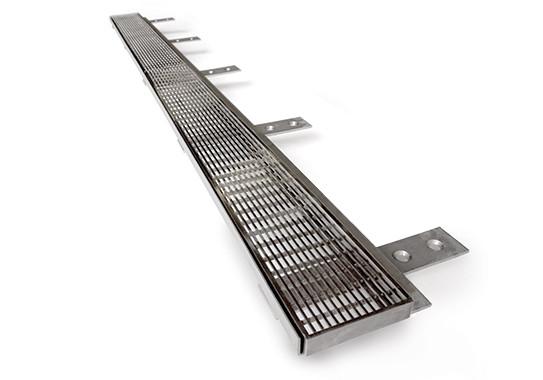

The Cantilever Bracket system was selected as it is fixed to the external slab prior to tiles/pavers being laid. This system provides stable support and houses the grates to resist dynamic loadings from pedestrian traffic entering and exiting revolving doors. Being mechanically fixed to the slab, the Cantilever bracket system does not rely on the building elements to support it. The grates are custom rolled and fitted to the bracket ensuring no movement or rocking will occur in service.

Details such as the channel radius were provided to Allproof by the designers. Allproof laser cut a flat template to confirm these dimensions on site. The template was used to manufacture a jig to ensure the bracket is fabricated to exact radius and dimensions of the curved revolving doors. Individual Wedge Wire spokes were rolled to suit the diminishing radius for the architectural grate. The system was then assembled and fabricated by hand before being put through a rigorous Q&A process.

Specifying the Cantilever Bracket for custom solutions provides confidence in performance by utilising a well-established and used design that has been rigorously tested both in-house and by independent NATA-accredited laboratories. The grates have been specifically designed for slip resistance, load capacities, hydraulic performance, maintenance, and durability, with features such as lock-downs to prevent movement from traffic or unauthorised access.

Other projects that have benefitted from Allproof custom curved channel drainage solutions are PWC tower in Commercial Bay, Massey University and Wai Ariki hot pools.

Where custom systems are required, details such as the radius, clear channel opening, imposed load, and traffic type will vary. Allproof uses advanced manufacturing equipment and facilities to produce premium drainage solutions for architecturally designed projects. Selecting Allproof helps ensure the accuracy of achieving details to the design intention and success of a project.

New Products

New Products

Popular Products from Allproof Industries

Popular Products from Allproof Industries

Posts by Andrew Smith

Posts by Andrew Smith

Most Popular

Most Popular