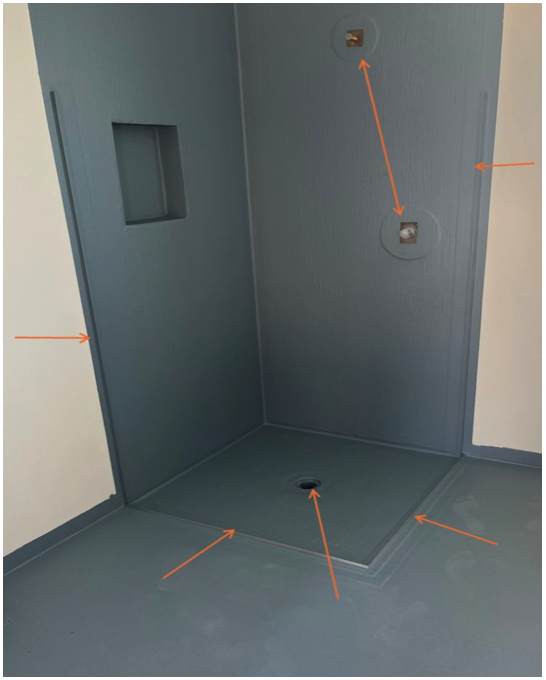

Here is what a typical pre-tiled shower should look like before any tiles are installed:

The photo shows how the new tiled shower has had the wall penetrations for the shower mixer and its outlet sealed with Cavity Wall Protectors. These provide a seal in the wall lining and also encapsulate the tapware body, preventing any moisture from entering the wall cavity, whether it be from water ingression or hardware failure by containing any moisture and diverting it back out the front of the tiles. They also provide easy access back into the shower mixer or tap for any servicing or maintenance requirements, without having to disrupt the finished surface.

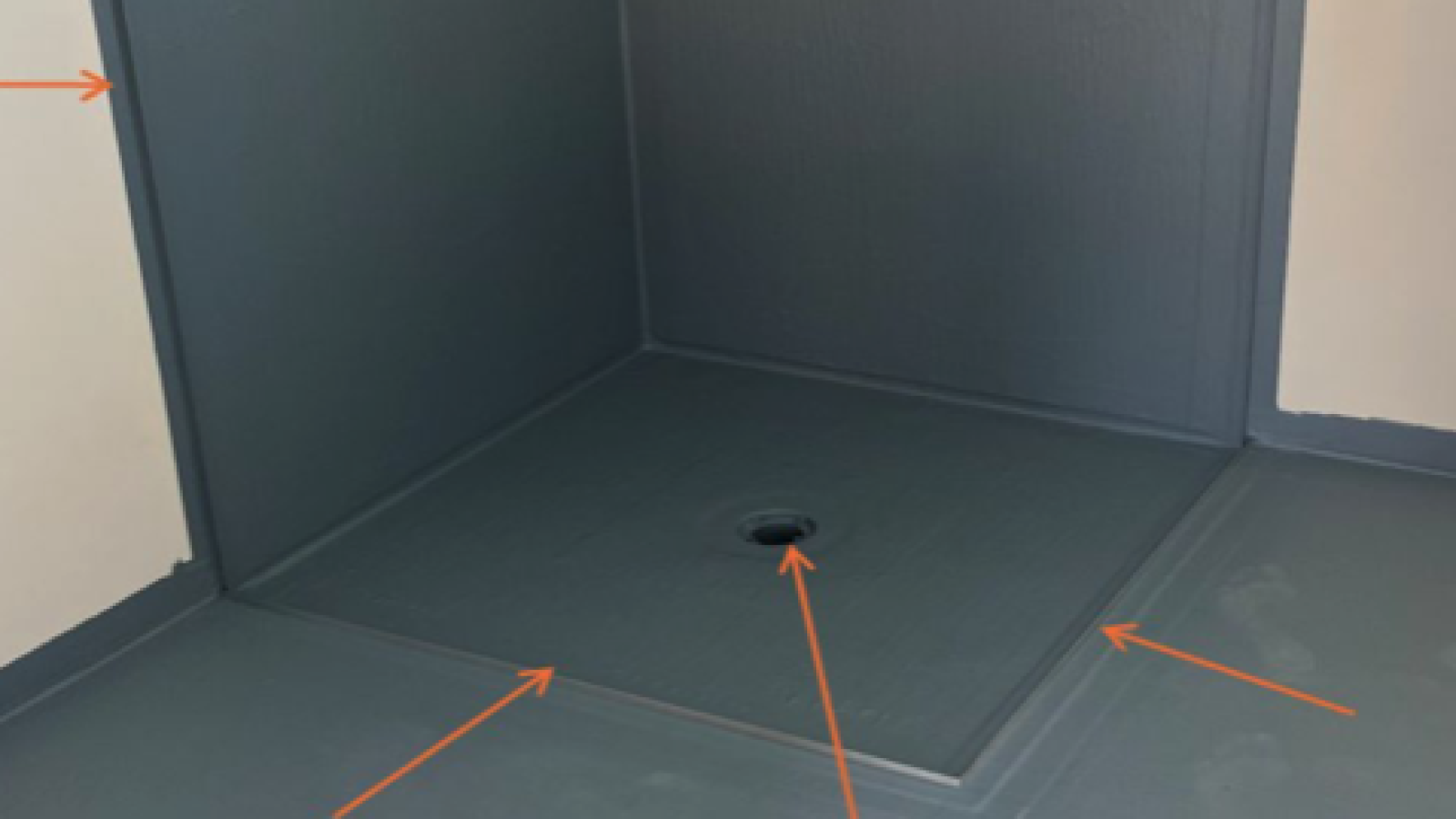

This shower also has Waterstops installed to the walls and floor of the shower to fully contain the sub-tile moisture that occurs for these areas. Waterstops keep the water inside the shower, where it is supposed to be. The Waterstops are embedded into a correctly installed, liquid applied Waterproof Membrane system, and the waste outlet has been correctly placed and waterproofed, flush with the substrate.

These are just some of the basics needed for a watertight shower and the above example has used E3/AS2 for Internal Wet Area Membrane Systems for the design and compliance pathways.

You can find information about E3/AS2 on the MBIE website or a full version of the IWAM code of practice is available from the WMAI (NZ).

Most Popular

Most Popular Popular Products

Popular Products