There are instances in Passive Fire construction where a tested fire stopping system can be applied to onsite variations through the Test Standard AS1530.4 — Section 10.12 Permissible Variations.

This section is commonly used for applying fire stopping test results to separating elements and metal pipe penetrations within the limitations of the standard.

Using permissible variations allows Allproof tested solutions on lightweight wall systems to be applied to concrete/masonry. Therefore, when finding a solution for concrete/masonry walls in Allproof’s technical manuals, please also refer to lightweight wall solutions as these results can be directly applied if the wall thickness is equal or greater and the achieved FRL is applicable to your requirements.

To provide an example, when looking for test results on a concrete wall minimum 150mm thick, Allproof offer 10 solutions for various pipe types and sizes. Using the support from AS 1530.4 permissible variations we can offer our lightweight wall testing with a minimum total wall thickness of 90mm. This adds an additional 130+ solutions to choose from if the achieved FRL matches your requirement.

With a wide and ever-increasing range of construction methods, products and materials, the scope for providing passive fire protection solutions is continually evolving. Educating our industry on permissible variations can help utilise solutions from other tested scenarios, greatly increasing the available results and catering to a wide range of applications. Knowing the technicalities of the standard allows for additional solutions that may have been overlooked before.

It is always advised to communicate with your project and fire engineering team that a Permissible Variation to the Standard AS1530.4 is being proposed as a solution, so that the Fire Rated Zones are considered appropriately before adopting. Additionally, reach out to Allproof for any details and advice as further solutions might be available or applicable through an alternative solution.

To highlight some common sections but not limited to, the below are some examples of how AS1530.4 10.12 Permissible Variations can be applied to increase the range of tested solutions available and its limitations:

Section 10.12.2 – Separating Elements

Commonly under this section, test results for lightweight partitions may be applied to concrete/masonry walls, provided that the concrete/masonry wall thickness is equal or greater than the total wall thickness of the lightweight partition. For example, a lightweight wall system consisting of 13mm plasterboard both sides of a 64mm steel stud equates to a total wall system thickness of 90mm.

Therefore, you can apply these test results on a concrete/masonry wall 90mm or greater and achieve the same FRL given in the report. However, it’s important to note the reverse does not apply.

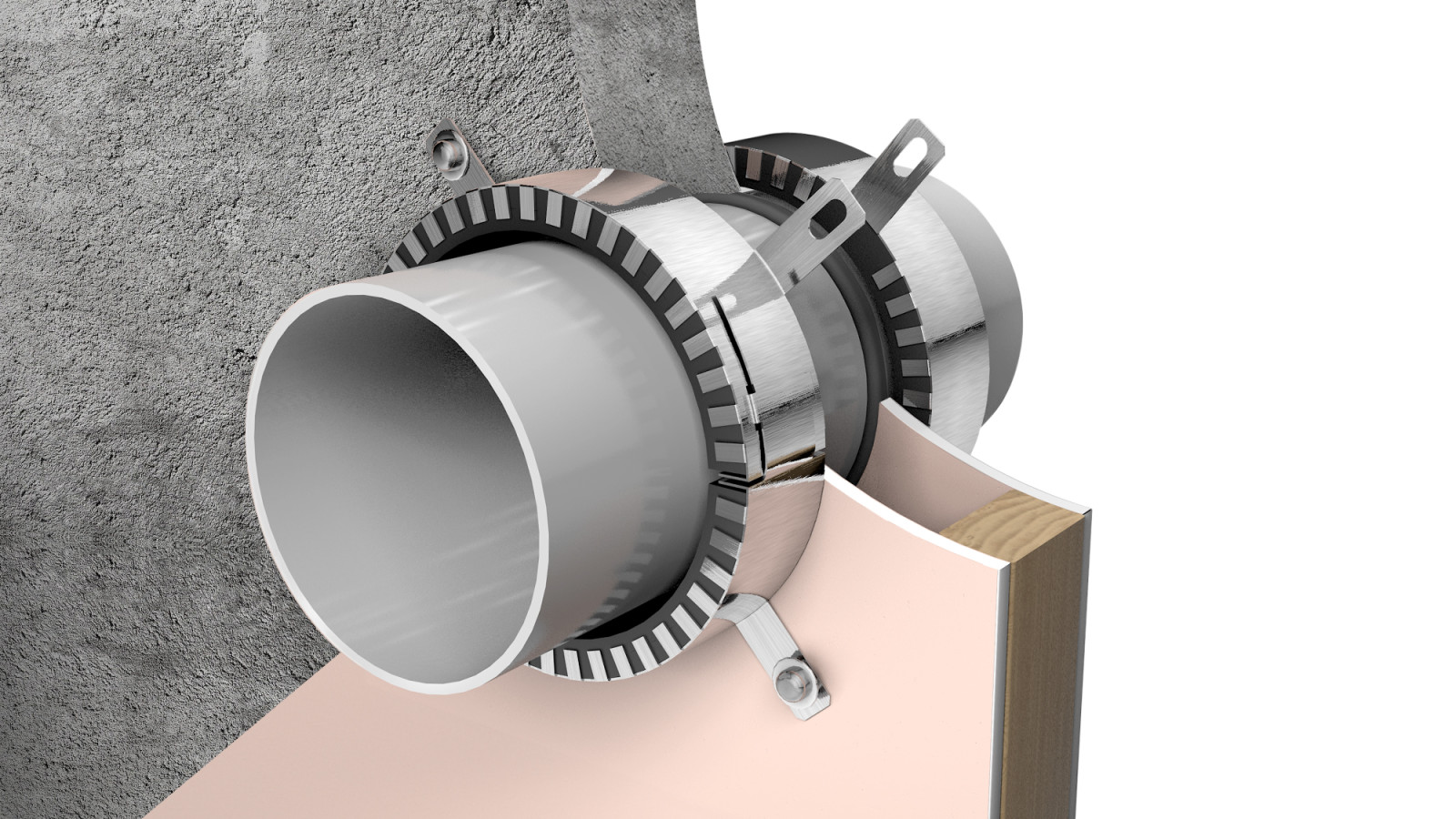

Section 10.12.3 – Metal Pipes

Test results obtained for steel pipes can be applied to copper and ferrous metal pipes using the table 10.12.3.1 provided under this section, so long as the fire stopping system and the separating element are identical to the referenced tested system.

Section 10.12.5 – Plastic Pipes

Test results obtained from a particular test shall not be applied to plastic pipes of different diameters, wall thicknesses or material types.

Results obtained from tests on penetrations through vertical separating elements shall not be used to assess performance in horizontal elements, and vice versa.

Penetrations not perpendicular to the plane of the separating element are acceptable, provided the fire-stopping system has similar exposure and dimensions to the tested prototype.

Most Popular

Most Popular Popular Products

Popular Products