When designing a shower there are a range of aspects that need to be considered. The area must be functional, safe, appropriate for the intended user and enjoyable to use. However, the most important function is to ensure it is designed to be watertight.

1. Waterproofing — membrane or tray

New Zealand Building Code (NZBC) Clause E3 Internal Moisture outlines important criteria that need to be adhered to when designing a shower. Clause 3.3.1.1 identifies that for a tiled shower (ceramic or stone) the floor and wall tiles must be laid either:

- i) Within a shower tray specified by the manufacturer as being suitable for the tiles; or

- ii) On a membrane specified by the manufacturer as being suitable for the tiles, substrate material and the environment of use.

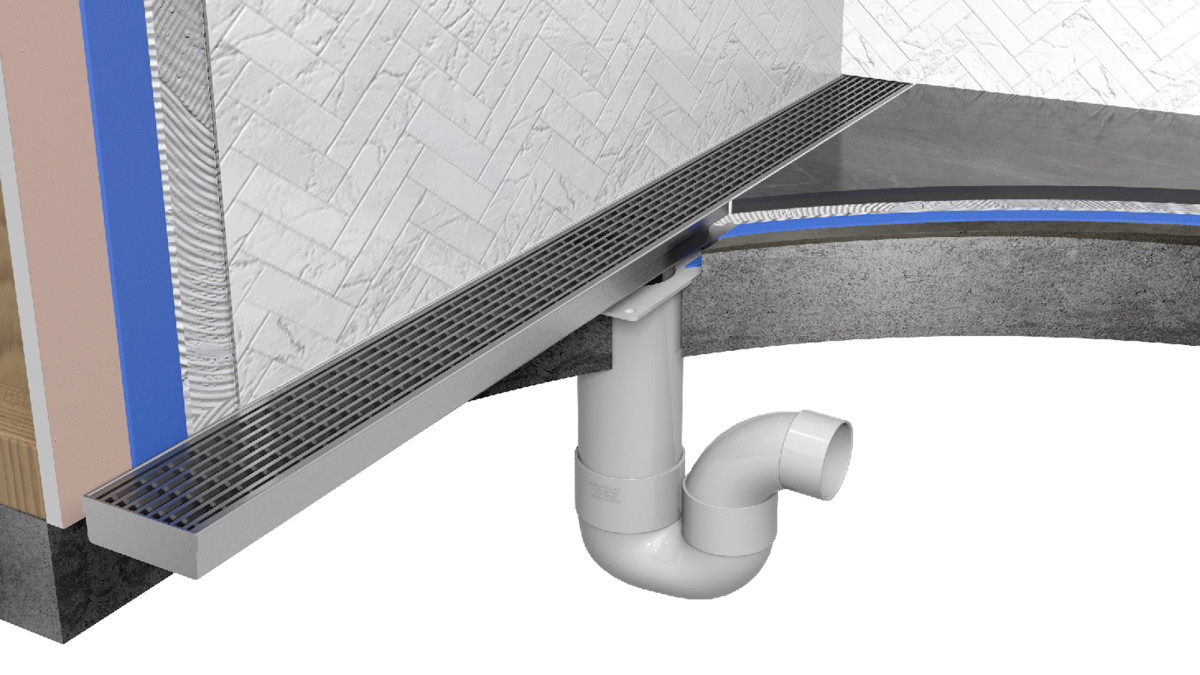

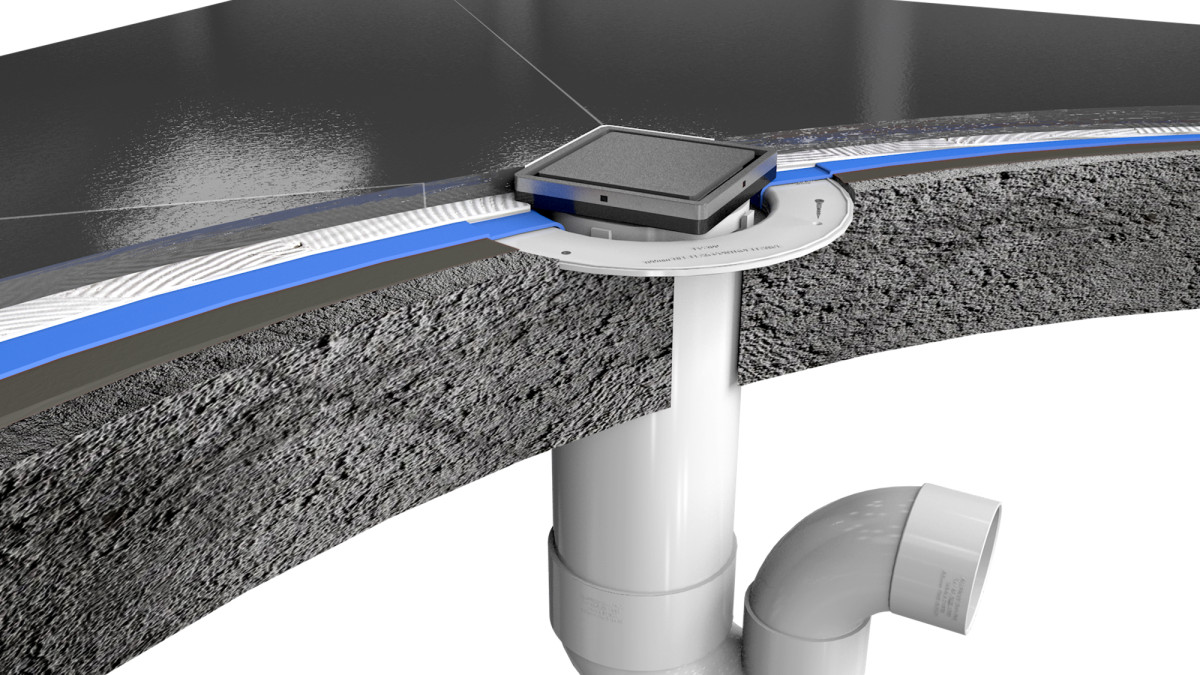

For membrane applications the entire shower area will be dressed with a sheet or liquid applied waterproof membrane in accordance with NZBC E3 Figure 5 and terminate at a drainage outlet. The membrane acts as the waterproofing element with tiles laid over the top as a decorative finish and to protect the membrane system. Allproof Industries manufacture a range of PVC leak control / puddle flanges that are compatible with all leading waterproof membranes. The flange provides a textured surface perfect for membrane adhesion and a PVC connection to the Drain Waste Vent (DWV) system that will incorporate a water trap / floor waste gully. Some sheet membranes will require a clamped outlet, for this application the Allproof Tilerite provides the ideal solution.

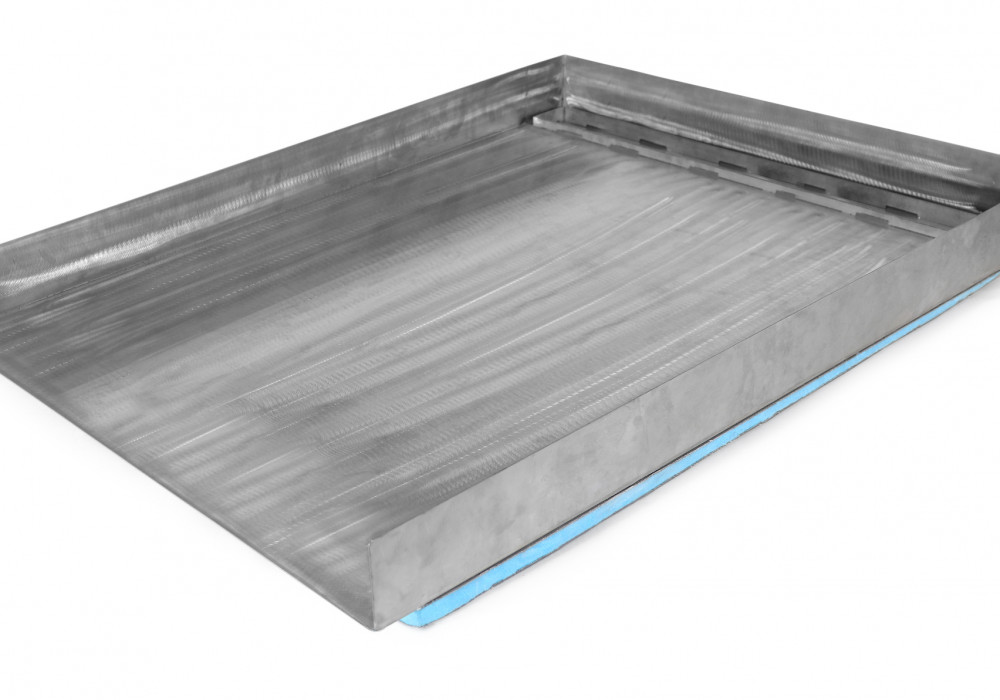

Allproof also manufacture custom made tile-over shower trays from stainless steel. The tray is made to measure the shower enclosure width and threaded outlet welded to the base as a connection to the DWV system. Waterproofing membrane from the walls and surrounding bathroom area is dressed onto the tray. A shower tray is designed to provide the ultimate level of moisture management and assurance in the shower area. It is an ideal solution for showers on upper levels and in projects where leaks could impact multiple tenancies and/or revenue streams (i.e. apartments and hotels).

2. Level entry or hob

A level entry shower provides a seamless transition between the shower area and bathroom, this can help make the bathroom appear more spacious. Additionally, this improves accessibility, removing any level changes in the floor that could be a hazard to some occupants.

NZBC E3 clause 3.3.2.3 states a shower that isn’t enclosed or has an upstand such as a hob (therefore, level entry) requires a 1:50 fall towards the outlet drain. AS 3740-2010; 3.4 states that a 1:100 fall is needed for showers that have a hob, however this should be confirmed with membrane suppliers as it is often recommended to have a 1:80 minimum fall.

A level entry shower will require some consideration regarding the flooring structure below. This installation will require cutting into the joists to allow fall to be created from the flooring substrate downwards so that the drainage outlet is positioned below the finished floor level of the bathroom. This may require an engineer’s input, especially regarding laminated joists. Often the shower area is trimmed out between the timber joists to create a set-down with a screeded fall formed in it.

A hob entry shower has the advantage of not needing to adjust the structure below. This can simply be laid on top of the existing flooring system with a fall created inside the hob rather than having to dig down into the structure below.

3. Point drain vs channel drain

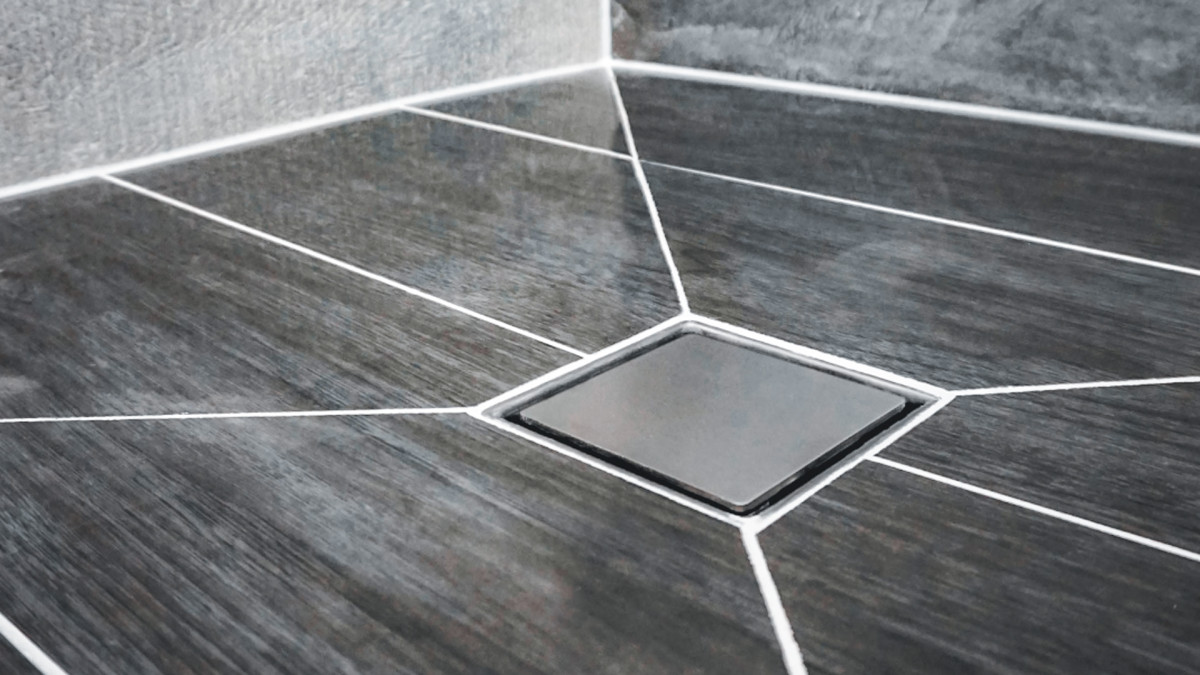

As mentioned above, a fall is required in the floor with a drain located at the lowest point. If a point drain is positioned in the centre of the shower the fall will slope towards it from all directions; this will result in cross-cuts in the tiles. Whilst this can reduce required set down, this aesthetic may not be desirable, especially with large format floor tiles. Setting an Allproof linear vision shower channel against a wall means the fall will only slope in one direction while maintaining clean lines and full tiles on the shower floor.

Additionally, it should be noted if a true level entry is desired, the channel needs to be placed against the wall opposite the entrance so that the fall direction doesn’t conflict with the level floor at the threshold.

4. Recessed shelves / wall niche

Utilising shower niches to create recessed shelves in wall cavities optimises the available space by removing fixings that protrude into the shower. The Allproof stainless niche has been designed to provide assurance as tight corners and joins may present vulnerable points in waterproofing. The stainless wall niche is fixed to the timber structure of the wall with waterproofing dressed onto the flange before tiles are laid over the top.

The Allproof stainless steel wall niche can be customised to each job giving the ability to create a wall-to-wall recessed shelf in a shower space.

5. Finishes and grate selection

Allproof provide a range of grate designs across their floor wastes to suit a wide variety of bathroom design aesthetics while also being durable and high performing. Popular selections are the Horizon shower channel grate and Elegance Plate which provide a brushed stainless-steel cover hiding the outlet while allowing for a drainage path around the edge. Additionally, the architectural wedge wire grate gives a premium finish to tiled showers.

The Invisi Drain or Tile Insert channel drain blend in with the surrounding floor tiles leaving a narrow but efficient drainage gap. This creates a discreet drainage outlet in the shower that is hidden but still easily accessible for maintenance.

Allproof’s drainage grate options have a range of finishes that can be used for design and material consistency with other bathroom fittings and fixtures. Powder coating in black, white, gun metal or any custom colour is also available.

Selecting Allproof

Allproof offer a large product catalogue with in-depth expertise for designing and constructing a waterproof tiled shower. Engaging Allproof during the design stage will provide specification insights so that the desired aesthetic, features and products can be achieved.

Case Studies

Case Studies

Popular Products from Allproof Industries

Popular Products from Allproof Industries

Posts by Andrew Smith

Posts by Andrew Smith

Most Popular

Most Popular