Wetrooms rely on membrane finishes to floors and walls to protect the building elements from moisture.

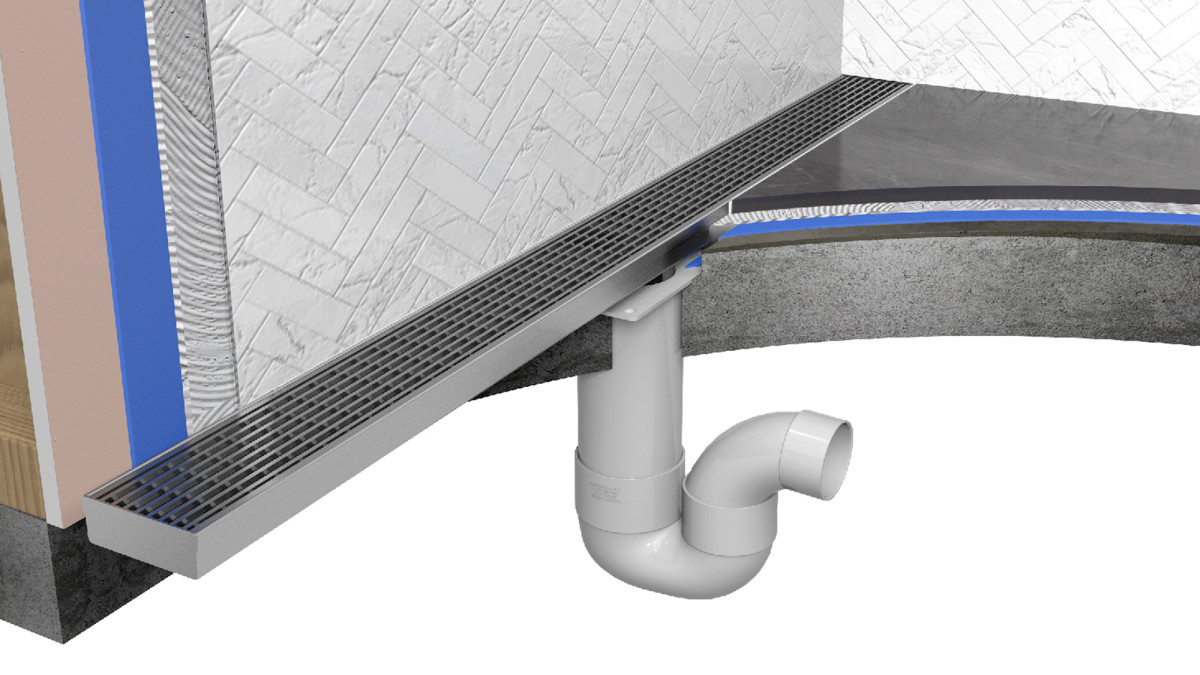

There are many solutions offered in the market for moisture protection and this will have an effect on the selection of the floor waste flange to ensure an economical, efficient and compliant termination to the membrane install. For tiled floors the NZBC E3 Clause 3.3.1 states that tiles must be laid within a shower tray or on a membrane that is specified as being suitable and provides an impermeable barrier for moisture. This allows for the passage of sub tile moisture into the floor waste gulley. Designers and installers should be aware that moisture can track behind tiles and must be managed and encouraged to escape to the leak control flange.

Membrane and floor waste suppliers will have details in their literature and attention should be paid to the requirements of each and how both systems interact. Selecting a flange that suits the membrane system and desired grate will improve the following steps in the construction timeline.

Membranes for a tile finish are either a sheet type or a liquid applied system.

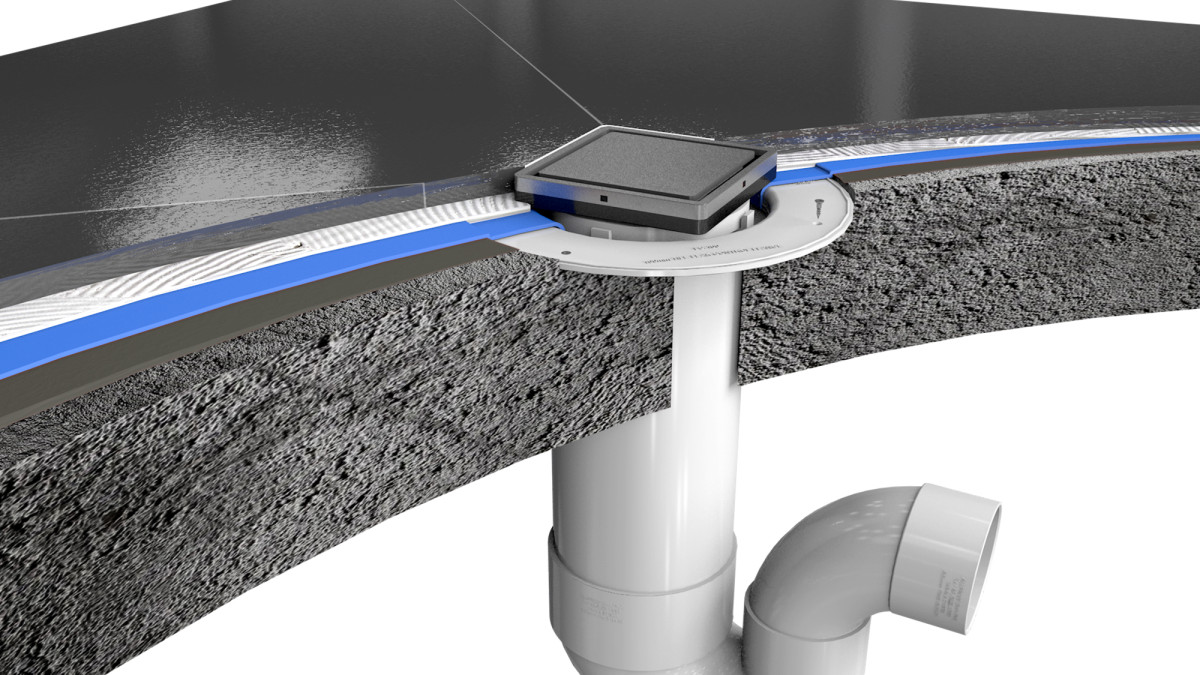

A sheet membrane will typically require a clamping ring to secure the edge of the sheet, like a roof drain or vinyl floor drain. It is important that the consented plans show the membrane system and outlet flange in detail. For a sheet membrane the Tile Rite system will allow for dressing and clamping of the sheet with an adjustable spigot to set the grate to height. This spigot also offers a drainage path for sub tile moisture to escape.

A liquid applied membrane will allow for a more traditional leak control flange to be installed, Allproof offers a range of options catering to install preferences and interaction with other systems. The most popular selection is the VF80, LC80 or LC100, allowing a surface area for the liquid membrane to be applied to. There have been evolutions in this selection, the Cyclone leak control flange makes install into the floor substrate easier, lends itself well to a passive fire solution and features the screw to height spigot as seen in the Tilerite install.

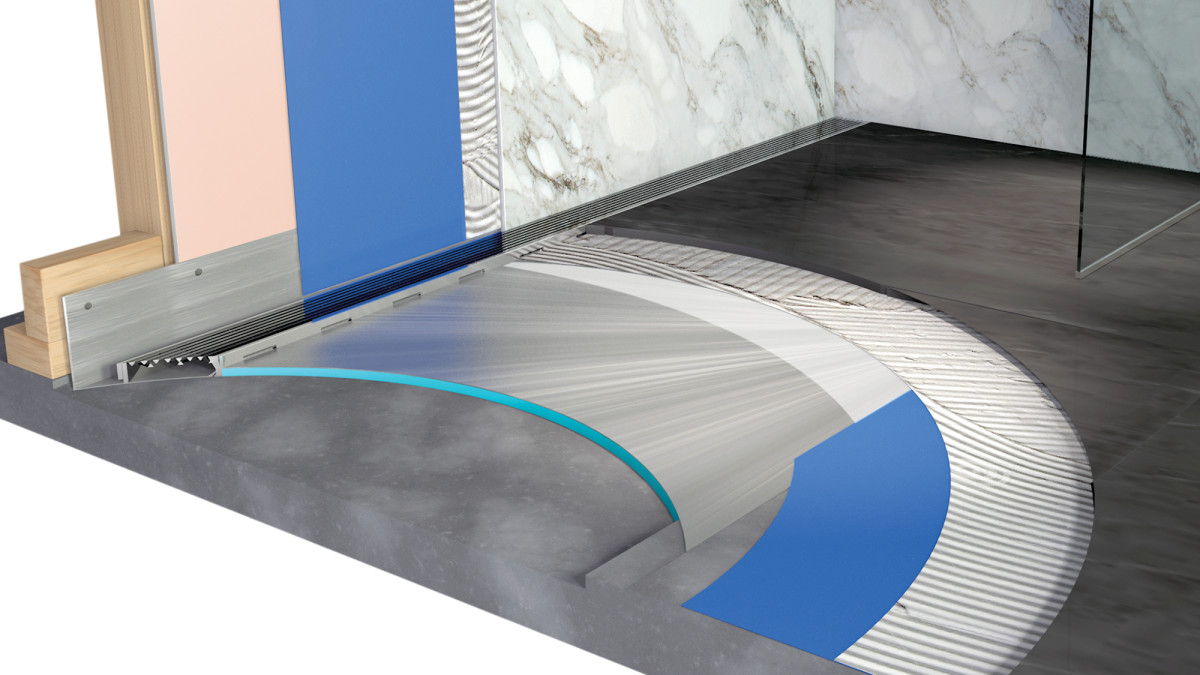

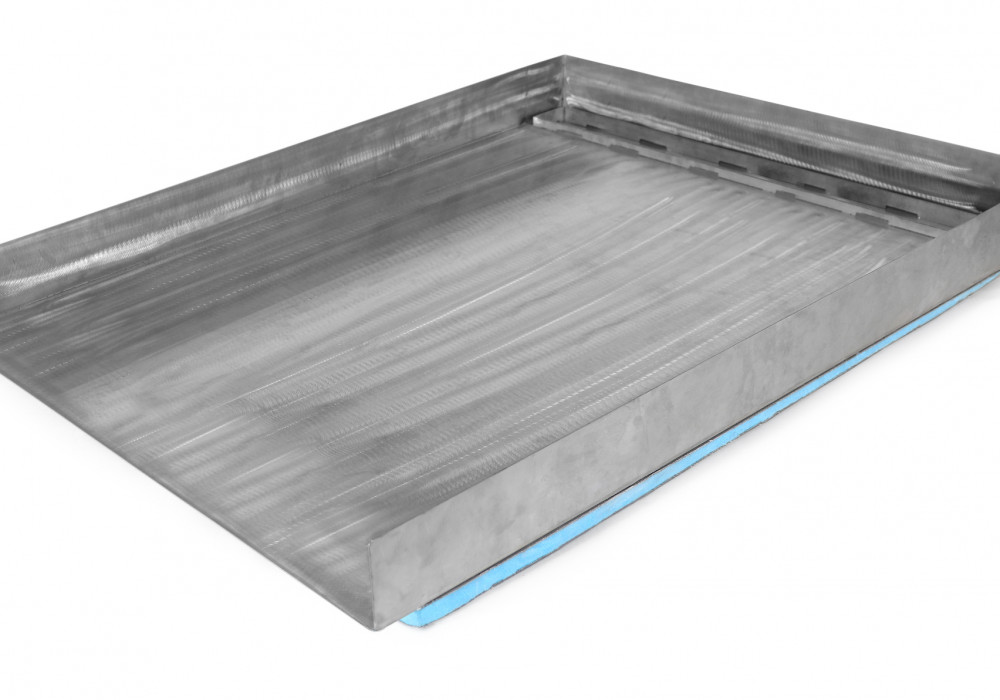

Membranes are an excellent and well-established system complete with extensive warranties. However, the superior solution for protecting building elements from moisture in the wet area is to specify a stainless steel tile over tray for the shower or wetroom end of the bathroom. With dimension being limited only by sheet size (3000 x 1700mm), the tray can be detailed to go under the shower area, incorporate a shower channel, and extend under the bath to provide a fully welded, flood tested moisture protection layer. Allproof offer a tile over stainless option providing the advantage of direct stick tiles, thus removing the membrane and screed from the high-risk area of the bathroom.

Designers and product specifiers should consider the compatibility of waterproofing systems, drainage fittings and floor / grate finishes when selecting products. Offshore manufactured drainage products aren’t always perfectly compatible with other systems and may cause delays or complexities during the installation process. Selecting NZ made full drainage systems designed for compatibility and compliance with the NZBC and a long in-service history ensures a premium solution that streamlines installation.

Allproof have designed, manufactured and supplied the New Zealand plumbing and drainage industry with innovative product solutions for over 35 years. Located on the North Shore of Auckland, Allproof utilise advanced manufacturing technology, solar energy and a range of sustainability initiatives such as using recycled materials to supply locally made premium solutions.

Allproof’s range of drainage systems are available with a selection of grates including the traditional chrome on brass, stainless steel, powder coated and electroplated finishes.

Researching reputable local suppliers provides projects with the best solutions for aesthetics and installation while enhancing performance, reliability and durability.

New Products

New Products

Popular Products from Allproof Industries

Popular Products from Allproof Industries

Posts by Andrew Smith

Posts by Andrew Smith

Most Popular

Most Popular