The changes, to be phased in over the next 1-2 years, will see thermally broken window frames become the norm around New Zealand, along with high performing Low-E double glazing. The manufacture and use of traditional aluminium window frames will decline sharply once these changes come into full effect.

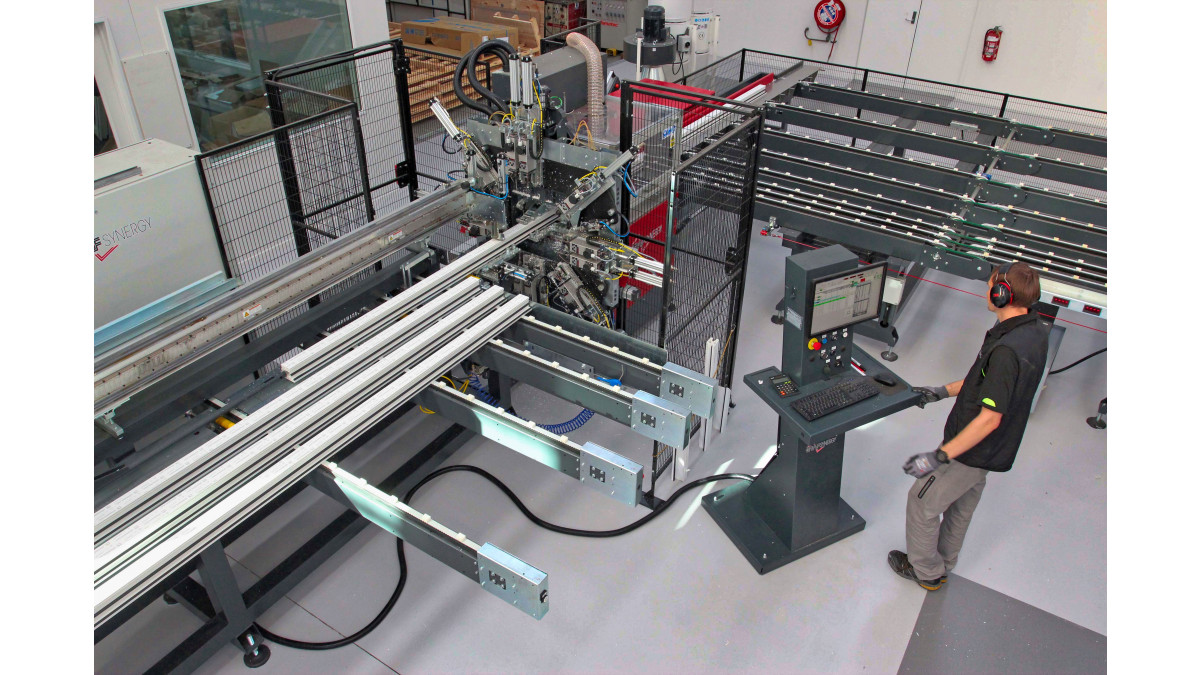

APL Window Solutions, proprietor of the Altherm, First and Vantage brands had anticipated the new statutory measures and are putting in place manufacturing capacity to cope with the expected rise in demand for its ThermalHEART range of products. APL’s thermal break machine capacity is being expanded and APL are well placed to continue supplying customers with market leading products.

The strengthening of the code provisions involves an up-spec of window and door profiles and will have pricing implications.

APL also has a high-tech. plant for the manufacture of Klima Series uPVC windows and doors which will also conform with the new H1 provisions.

Government are allowing a phase-in period over the next nine months so that the window industry can put in place appropriate manufacturing capacity. This transition time will end on 3 November when the new insulation requirements will become mandatory. The northern part of the country, including Auckland, will have a two-step approach, with the R-value requirement lifting to R0.37 (from the current R0.26) on 2 November 2022, and then moving up to R0.46 from 2 November 2023. Other parts of the country will have to conform to the new code provisions (R0.46 or R0.50, depending on the region) by 2 November 2022.

New Zealand is to move from the existing three Climate Zones to six, to allow a more nuanced approach to climatic factors and window suitability. APL window manufacturers supplying across different climate zones will work with customers to ensure that their windows, as supplied, are compliant at the site location.

The code changes will require thermally broken aluminium or uPVC frames together with high-performance double-glazed units with Low-E coating and Argon fill. Even if triple-glazed units are used, they will likely require Low-E and Argon fill as well as thermally broken aluminium frames.

APL’s glass sister company AGP (Architectural Glass Products) has high production capacity and anticipates no problems in supplying the market with high quality, high-performance glazing units of the standard required by the code changes. Its Solux-E product with low-E coating, Argon gas and Architectural Thermal Spacer is well suited to the stricter standards.

For specifiers wishing to arrange an H1 presentation, either online or in person, register your interest here.

New Products

New Products

Popular Products from VANTAGE Windows & Doors

Popular Products from VANTAGE Windows & Doors

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts