When selecting waterproofing materials for low pitch roofing, a 'systems' approach is not negotiable.

It can be tempting to treat the waterproofing membrane independently from the accessories, as these are often deemed as secondary and less important components. They can also usually be procured more cost-effectively from local suppliers instead of from the principal membrane manufacturer. However, despite the membrane covering the greatest area, the watertightness of a building is dependent on the system in its entirety.

Cobbling hybrid systems together is dangerous and there's no room for it in the waterproofing industry. Hybrid systems incorporate a conglomerate of various suppliers' components, such as membranes, adhesives, sealants, flashings and accessories. Very rarely are these properly tested for compatibility in the long term.

In contrast, when using a membrane manufacturer's lab and field tested, internationally warranted system, its elements can be installed with confidence.

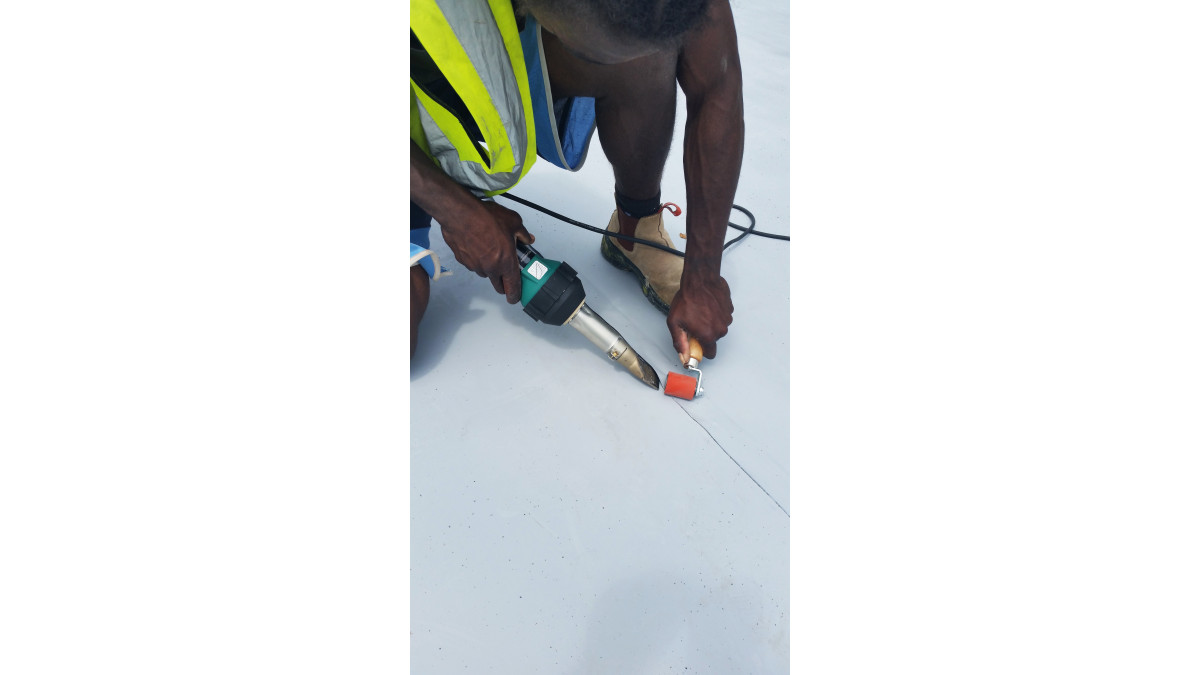

When it comes to thermo-plastic membranes, welding incompatible plastics together without an intimate knowledge of their composition can be disastrous. For example, PVC, TPO, or TPE membranes welded to say, polyethylene accessories which are more commonly used with rubber membranes can render a surprisingly good initial bond, which gives a false sense of security. Over time, the weld between these incompatible plastics becomes brittle and can eventually break open.

ONLY LIKE FOR LIKE MATERIALS GO TOGETHER

There can be instances when a membrane manufacturer does not make all of the accessories required for the market. In this instance, an empirically disciplined and fully documented process must prevail in order to procure components that will be compatible with the membrane, and to ensure it lasts well beyond the Building Code's minimum durability requirement of 15 years for roofs and decks.

Viking Roofspec recently commissioned a division of the University of Auckland to scientifically 'diagnose' the chemically correct plastic for making accessories compatible with the Enviroclad TPO membrane, as its overseas membrane supplier didn't make these. These locally fabricated items are now integral parts of the Enviroclad membrane system.

As well as minimising risk, a low pitch roof installed to specification by a licensed applicator using the manufacturer's full system is usually more aesthetically pleasing, as the accessories match the look of the membrane that they were designed to be installed with.

This systems principle should not only apply to all low slope membrane systems, but to all construction products.

Note: Viking Bituclad has now been replaced with three fit for purpose solutions: Viking GM Lybra, Gemini and Phoenix Super.

New Products

New Products

Popular Products from Viking Roofspec

Popular Products from Viking Roofspec

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts