When designing a bathroom, the product selection for the plumbing systems and fixtures can have a real impact on the embedded carbon of the project. Selecting products manufactured locally by a supplier that is taking tangible steps towards reducing carbon can have a huge positive effect in sustainable construction.

A New Zealand manufactured waste system immediately reduces the embodied carbon in the products as pre-manufactured and imported fittings are inefficient to ship. This embodied carbon is multiplied by the sheer distance of the New Zealand market. Importing a container of pre-made fittings is less economical when compared to a bag of the raw material. A container of pre-made fittings will mostly consist of air, compared to a fully packed shipment wall to wall of material in pellet form. When comparing pre-manufactured fittings to raw material in pellet form, the volume can be reduced by up to 85%.

As part of the WaterMark Certification process, the manufacturer is externally audited to ensure that the production process follows best environmental practice. The criteria for this includes the use of in-house recycled materials minimising waste and a strict QA processes. A WaterMark Certification from a local manufacturer provides the end user with an assurance that the product is fit for purpose and made with the environment in mind.

Allproof are going one step further; by installing 449 solar panels on their manufacturing facility, Allproof are sourcing their own renewable energy to power production equipment, fork trucks, electric vehicles and offices. The solar panels generate up to 1,000kWh per day providing nearly 50% of the buildings total demand.

The environmental economics and processes for local manufacturing means that there is a clear advantage when reducing carbon by selecting NZ made. The Allproof leak control flange is just the start of the system of a locally made floor waste system. The gulley, flange, fire collar and decorative tile insert Invisi grate is all made in house with the best practice in mind. For this reason Allproof’s floor wastes are matched perfectly to the local environment, meet with approval from installers, and give specifiers confidence that the chosen system is one that will meet the demands and warranty requirements of local building codes.

When it comes to a shower channel, Allproof offer stocked ‘off the shelf’ sizes and custom design options. The custom option allows the channel to be measured and fabricated locally after tiles are installed to ensure that the perfect finish is realised.

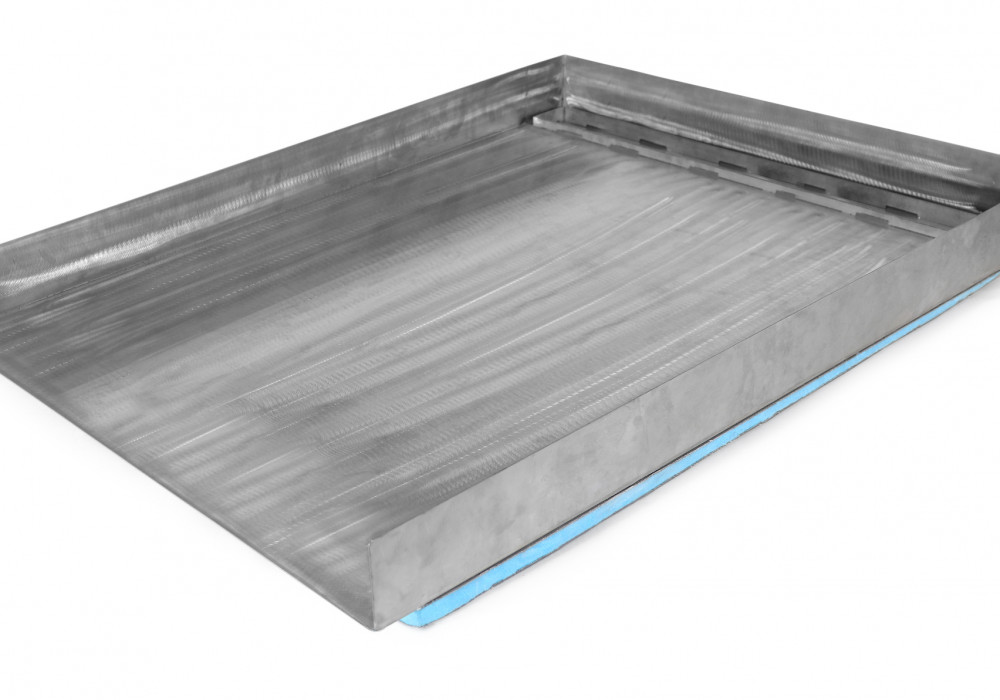

Additional to custom shower channels, Allproof also manufacture custom stainless steel tile over trays. A tile over shower tray offers a premium waterproofing solution to provide the specifier and end client with peace of mind. The laser cut, CNC folded stainless steel tray is adhered to an engineered XPS base that creates the falls outlined in NZBC E3 and enables the tiles to be stuck directly to the tray. This removes the requirement for screed and membrane in the tray. As part of the production and QA process the tray is flood tested to guarantee the result Allproof have built their reputation on.

New Products

New Products

Popular Products from Allproof Industries

Popular Products from Allproof Industries

Posts by Andrew Smith

Posts by Andrew Smith

Most Popular

Most Popular