It’s probably fair to say that specifying an elevator isn’t something that ranks high on the list of daily activities for most architects. But with an ageing population and medium density trends making multi-storey homes the new normal, it is something specifiers will increasingly need to get comfortable with.

With this in mind, Kiwi-made Powerglide Elevators have developed a Design Support Programme that helps specifiers and builders streamline the design and consent process, as well as avoiding costly delays during construction.

Allan Fullerton, who heads the Specification Team, encourages architects to contact them early, in order to get the most benefit from their expertise and experience.

“The current approach to elevator design is often to draw a 1m x 1m box in the plan and relegate it to the ‘later’ file. By the time we get involved, it’s harder for the architect to accommodate the minor design tweaks that could have significantly enhanced the usability and overall lift experience for the homeowner,” says Fullerton. “The earlier we get involved, the more meaningful advice we can provide, and the easier we can make the process for all involved.”

Powerglide is able to provide comprehensive design support because the lift mechanism is its own proprietary design, and the entire process, through design, manufacture, and installation is managed locally, by an in-house team. According to Fullerton, who created the first Powerglide Elevator back in 2003, this gives them a significant advantage when it comes to supporting the specification process.

“It means we know the system intimately and have the flexibility to make changes at any stage. Our Design Support Programme reduces the turnaround time of all aspects of design, engineering, and compliance by automating many of the specification tasks. As an example, we can provide same-day turn-around for PS1 and associated documentation for building consent lodgement.”

The Powerglide information is clear and accurate, based on the experience of over 900 installations, working to the requirements of consenting authorities throughout New Zealand.

Architects contacting Powerglide for technical information and resources will find themselves speaking to an expert in all aspects of lift specification for residential, commercial and medium-density projects.

The typical Design Support Programme is broken down into 5 stages:

Stage 1: Early Design Stage

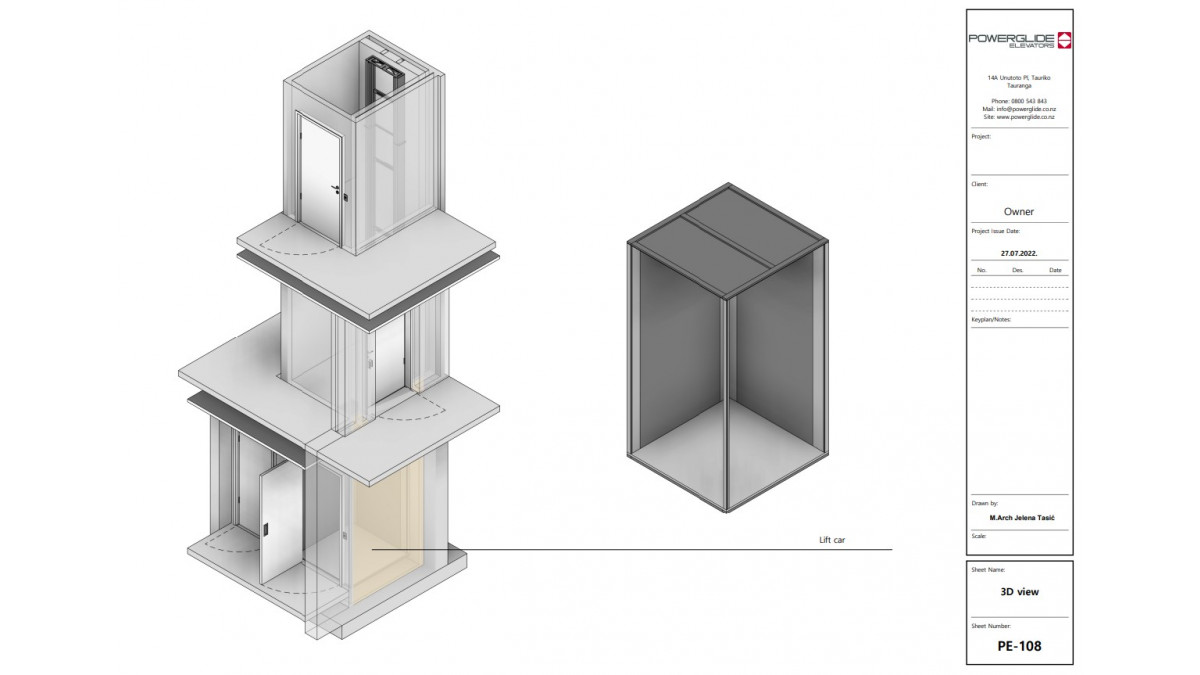

- Powerglide provides simple and clear design guidelines to get to the preliminary design stage, enabling the designer to firm up sizes, layouts, etc.

- Powerglide’s in-house drafter delivers accurate lift drawings for specifiers and builders in formats to suit ArchiCAD, AutoCAD, Revit, and most other design platforms, as well as a printable PDF for sites.

- Documentation is also provided for structural engineers, assisting with the lift shaft design.

- As Powerglide Elevators are designed and manufactured in NZ, lifts can be customised for a project. This gives the designer complete flexibility as opposed to the typical one-size-fits-all situation.

- The Powerglide Design Team is available with expert support and suggestions throughout.

Stage 2: Pre-Consent Design

- Powerglide will assist with any ongoing changes to the design that may affect the lift shaft, helping the designer with even the smallest details.

- Drawings are updated as required, supplying a full set of lift drawings for use by the designer in their own plans, and by the builder on site.

Stage 3: Consent Lodgement

- Powerglide provides same-day service for PS1 and associated documentation for building consent lodgement.

- The prior acceptance of Powerglide's system with all consent authorities means lift-related RFIs are significantly reduced, with none in most cases.

- Powerglide's NZ-made system is specifically designed to meet the NZBC requirements and the system is a recommended solution of NZ's leading lift certification consultants.

Stage 4: Construction Stage

- Powerglide's specification team will assist builders with advice and support during construction of the various elements of the lift shaft and lift plant room.

- When the situation on site doesn't reflect the drawings or plans, Powerglide will help the designer and builder to make the necessary changes to accommodate the discrepancies. If necessary, the lift car design can be altered, even at a late stage.

Stage 5: Post Construction

- Upon completion of the installation, Powerglide will quickly deliver the required post-installation compliance documentation.

- This includes PS3 and PS4, guarantee documentation, service planning when required, as well as after-sales support.

New Products

New Products

Popular Products from Powerglide Elevators

Popular Products from Powerglide Elevators

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts