January 2016 marked the completion of MAXRaft's role in a landmark project; supplying and installing their innovative fully insulated slabs for ten new homes commissioned by Queenstown Lakes Community Housing Trust. The trust is responsible for managing and delivering affordable homes to those in the community who cannot afford them and selected Evolution Homes (a division of Rilean Construction) to deliver the homes for their clients.

"At Evolution Homes the focus is building energy-efficient houses for our clients," explains Contracts Manager Lisa Burroughs. "Our goal for this project was to ensure these homes were built to the same high specifications and excellent energy efficiency associated with our brand."

"Part of the energy-efficient puzzle included each home having a fully insulated MAXRaft slab," Lisa adds. "Which along with efficient building techniques beyond the slab gave a complete thermal envelope from the floor, up the walls and in the ceiling."

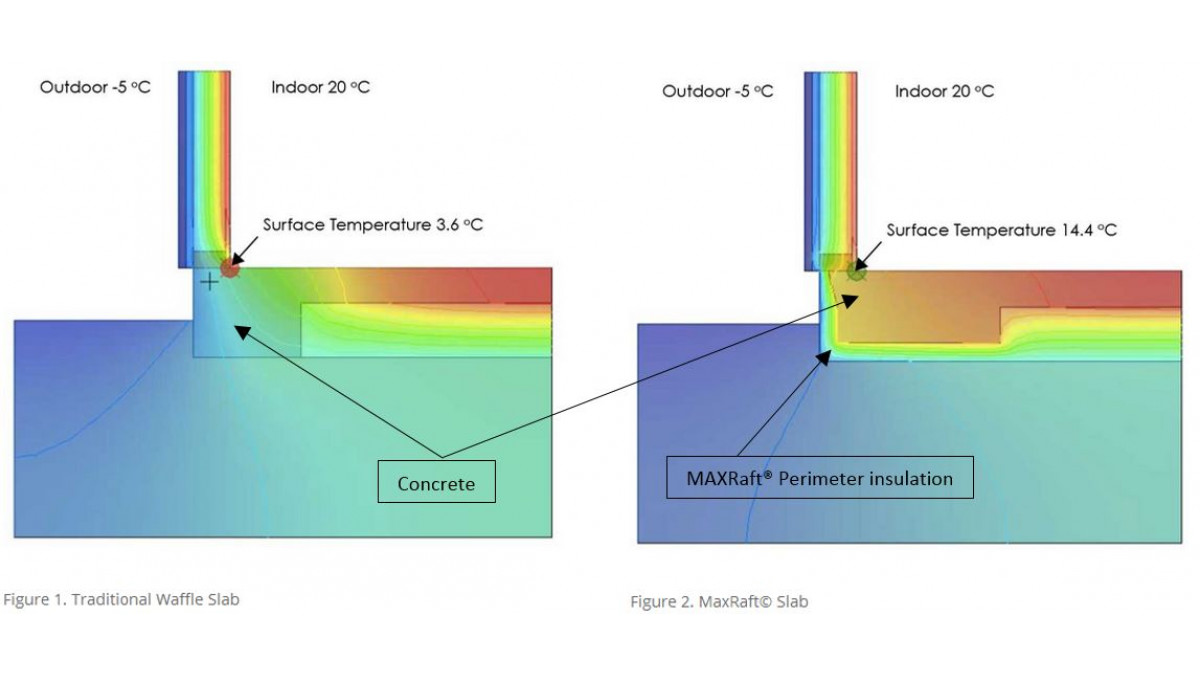

A CodeMarked product, MAXRaft is based on three key components which together achieve an R-Value of approximately R4.5 according to floor type.

- Perimeter footings are designed to create a thermal break, reducing heat loss from the floor where up to 80% of such loss occurs.

- MAXRaft's load bearing thickenings can support the walls of the home, while maintaining a complete thermal envelope around the foundation.

- MAXRaft infill is cost effective, with one trailer of MAXRaft to a standard size house (approx 180m²) equivalent to 24m³ of concrete.

All MAXRaft slabs are specifically engineered for each project, then delivered to site in pre-cut segments along with a site-specific panel plan. The system can be put down in a few hours by a team of two people, and is then ready to receive the reinforcing later the same day, and concrete when ready. It's a time-efficient onsite process that offers a significant advantage, especially on a multi-unit project, says Lisa.

"It eliminates the requirement for site concrete for footing and concrete block work. This reduces the number of trades on site, and allowed us to shave about four days of each build and meet our tight project deadlines."

For Lisa the decision to use MAXRaft was an obvious one, "I've used it on a number of projects in the last five years and now know many happy (and warm) clients because of it."

The project is due for completion in Spring 2016.

MAXRaft can be specified as a complete slab install or supply only, and also has a durable and watertight coating system available.

Project: Queenstown Lakes Community Housing Trust, Shotover Country, Queenstown

Main Contractor: Evolution Homes (a division of Rilean Construction)

New Products

New Products

Popular Products from MAXRaft

Popular Products from MAXRaft

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts