MAXRaft is a New Zealand owned and operated company dedicated to delivering high performance insulated flooring systems that increase thermal performance and energy efficiency in homes and buildings across the country. Their systems are carefully designed and manufactured to minimise and manage waste, ensuring a circular economy.

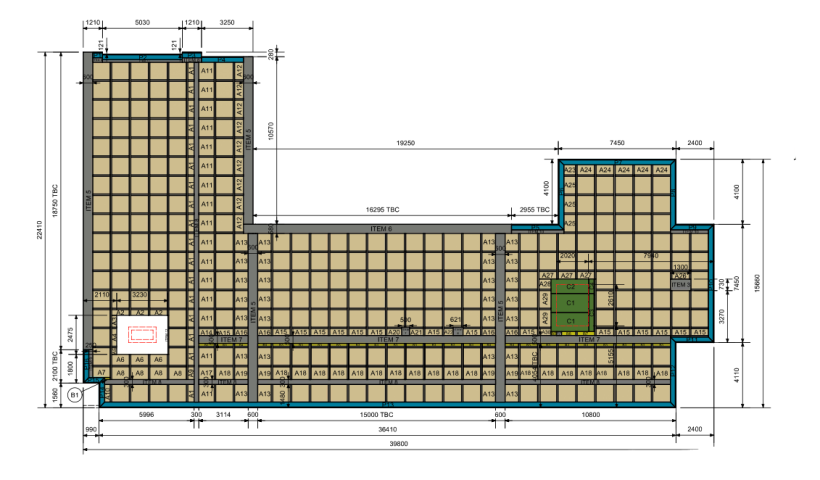

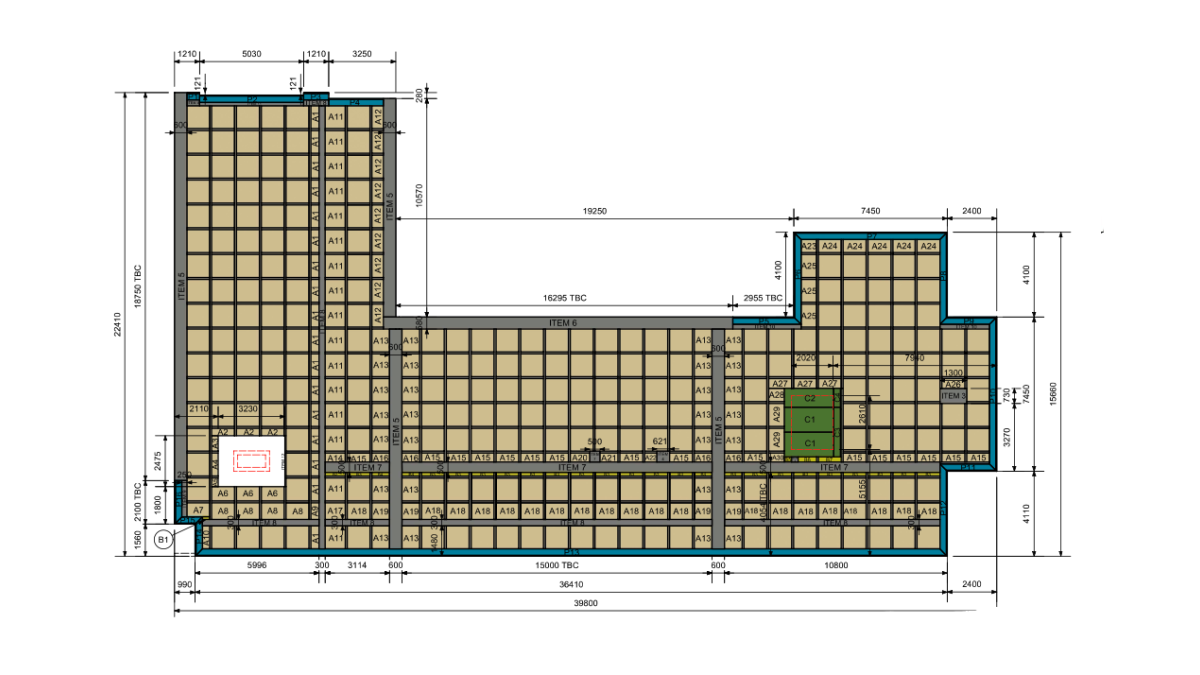

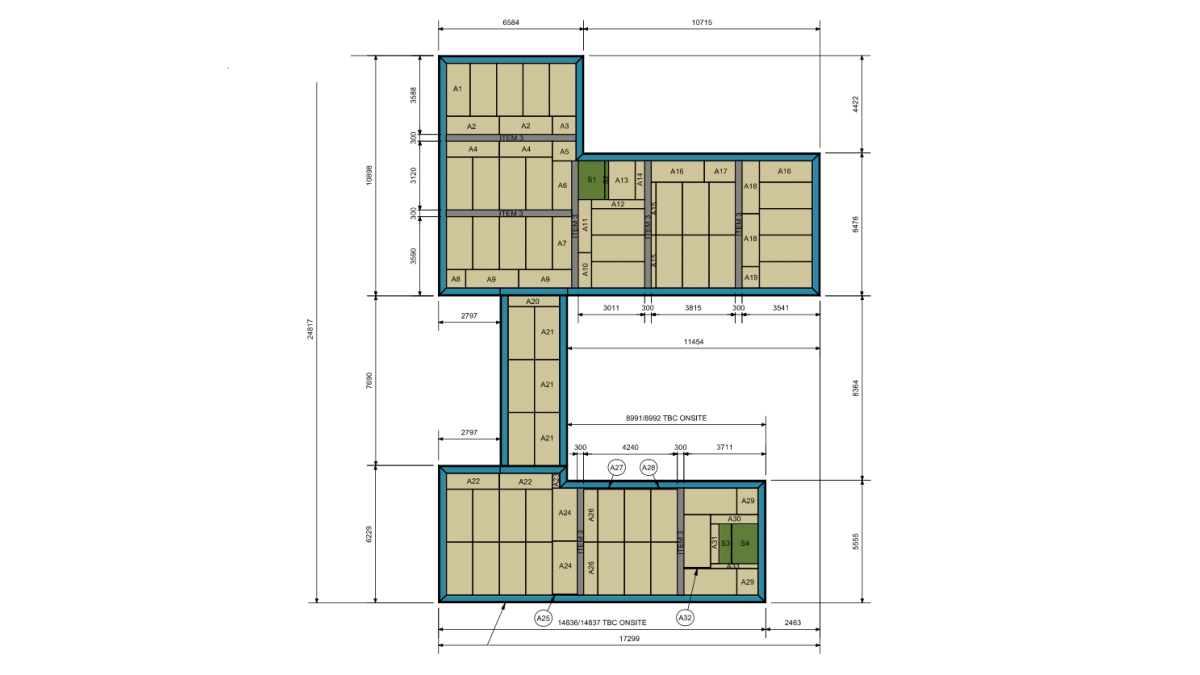

Site-specific panel plans free of charge

The first step the MAXRaft team takes to reduce waste is to produce site-specific panel plans for their flooring systems, free of charge, so only what is needed is manufactured and sent to site. These panel plans, designed by MAXRaft’s in-house QS team, ensure that the design meets structural requirements, matches the ground type on site and takes into account all load bearing and point loads.

Pre-cut systems to reduce waste

All components of MAXRaft’s insulated flooring system are then pre-cut to measure offsite following the site-specific panel plan. This makes installation simple, with all components delivered ready for install, and minimises offcuts to almost zero.

100% recyclable offcuts

Any offcuts that are produced on site, such as from details like window rebates, can then be returned to the MAXRaft factory for recycling. These offcuts are recycled into new products like slabs, with each component of MAXRaft’s system containing approximately 15% recycled material.

Over 10 years of sustainable manufacture

From day one, MAXRaft has been committed to leading the way in sustainability and reducing the environmental impact of their products. “We try and keep it simple but clean,” says Ange Smith, Business Development Manager, MAXRaft. “There’s a circular economy in what we do — when the plan comes through, how it’s detailed, how it’s cut, how it’s handled on site and how it’s returned. And it’s something we’ve been doing for over 10 years.”

To learn more about MAXRaft’s insulated flooring systems, contact MAXRaft

New Products

New Products

Popular Products from MAXRaft

Popular Products from MAXRaft

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts