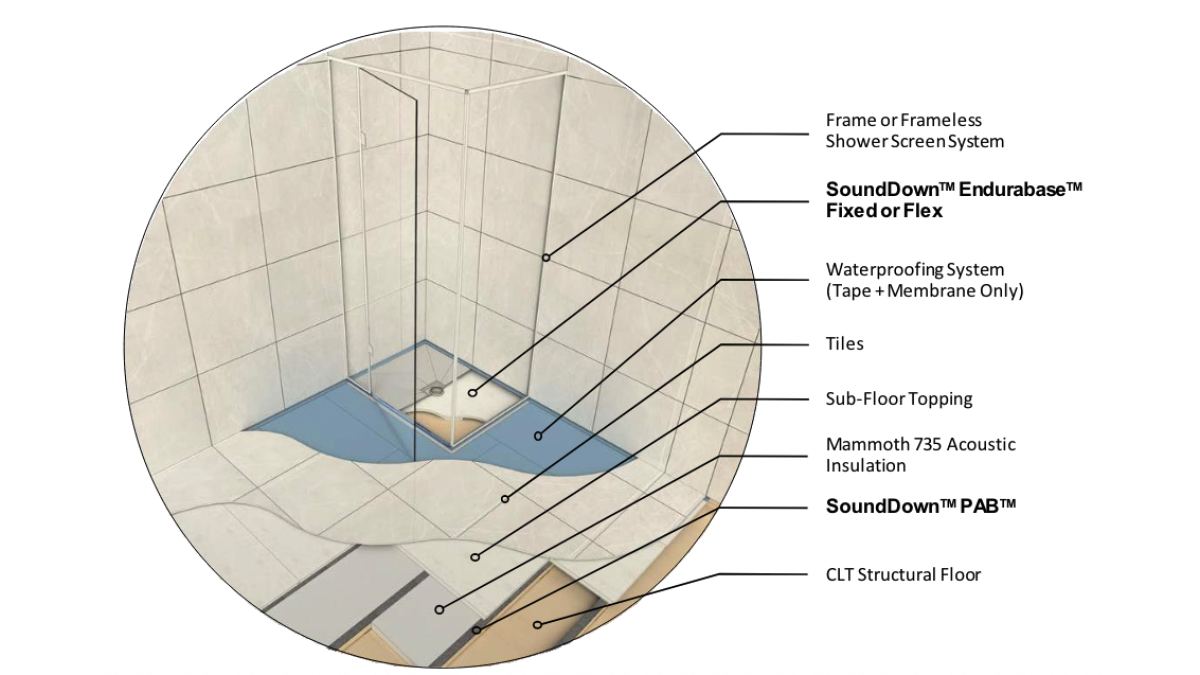

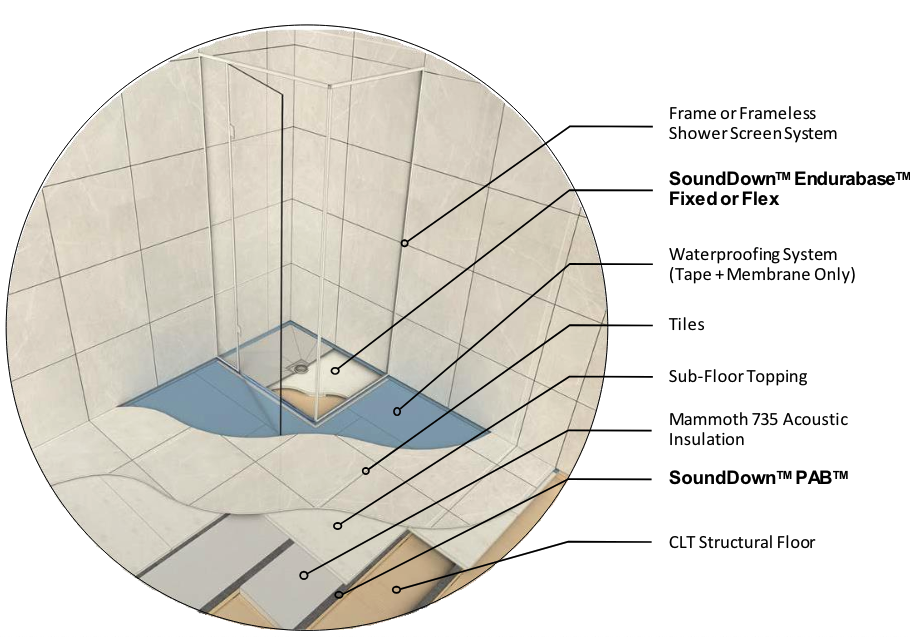

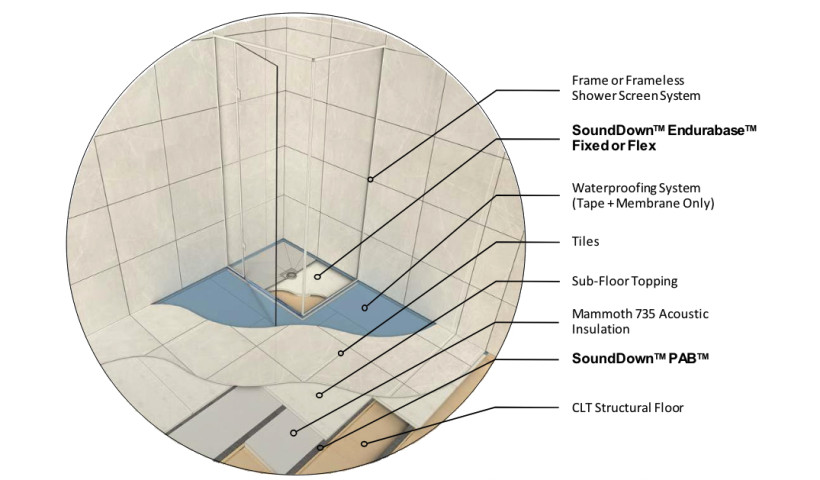

SoundDown Endurabase is a seamless prefabricated shower base system that ensures watertight wet areas and eliminates the need to build up the shower floor with wet screeds, reducing on-site labour.

Developed to be compatible with raised acoustic floors in apartments and townhouses, with an aim to simplify the creation of a seamless flush shower entry whilst guaranteeing compliant floor falls, the SoundDown Endurabase system is composed of two fundamental components: a prefabricated sub base and a pre-formed tileable tray. These are shop drawn as a system to meet specific requirements around the height and size of the shower, manufactured off site, and delivered for quick and easy installation with no need for complicated build-ups and additional screeding.

The prefabricated sub-base

The SoundDown Endurabase system uses a Maglock DragonBoard base which is acoustically isolated and sits on the floor. The sub-base is available in heights from 25mm to 40mm to meet height requirements. The unique magnesium oxide and fibre reinforced magnesium sulphate composition of the Maglok board provides an ideal substrate for a waterproof membrane and surface flooring.

To meet the stringent requirements of E3/AS1, the designer must specify a suitable waterproofing system to be installed on top of this sub base. The surface element must be continuous, impervious and be either covered or have the joints sealed. An integrally waterproof sheet material such as polyvinylchloride will meet the acceptable solutions (E3/AS1).SoundDown recommends using the ARDEX waterproofing system detailed on page 10 of the SoundDown Design Guide; this system not only meets the requirements of E3/AS1 but provides a warranted solution for wet areas. Where specifying an alternate waterproofing system, consult the waterproofing manufacturer to confirm suitability of products and warranty terms and conditions.

The pre-formed tileable tray

The shower tray or wet floor sits on top of the sub base, and is manufactured to project requirements to ensure the system meets level entry or whatever height is needed. The SoundDown Endurabase system uses two industry-leading shower tray options depending on project requirements:

- For fixed size showers: The SoundDown Endurabase Fixed system comes in a set of standard shower sizes with a Henry Brooks Fibreglass Tray.

- For project-specific shapes and sizes: The SoundDown Endurabase Flex system is custom designed for unique shower sizes and shapes, with a pre-formed Oben cement coated XPS-core shower base.

- For wet rooms: The SoundDown Endurabase Flex Wet Room system features the same XPS-core shower base as the Flex system, available in any size to meet wet room requirements.

The SoundDown Endurabase system is ideal for multi-unit residential and commercial buildings where it can simplify the design of wet rooms and save crucial time on site. It has already been specified on a number of retirement villages, where it brings the benefits of time savings, long lasting reliability, and the peace of mind of a 25-year system warranty.

“What’s unique with SoundDown Endurabase is that it is premanufactured and is installed very quickly,” explains Warren Tretheway, SoundDown. “So it minimises a big amount of time on site typically needed for wet trades while providing a resilient wetroom or shower space. With mass timber that's very important — if you get moist penetrations into CLT substrates that can be catastrophic long term, so it’s very important that you deliver these resilient wet room systems.”

To learn more about how the SoundDown Endurabase system can help your projects, get in touch with the SoundDown team.

New Products

New Products

Popular Products from Build Anatomy

Popular Products from Build Anatomy

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts