In a recent project we were involved in, the building use included outside broadcasting of live events, including sports fixtures and social/community activities. The television crews need to run cables across vast distances to get their equipment in the right position. Access to these locations usually requires the cables to be run on the outside of the building. This is time consuming and requires all manner of health and safety compliance.

Where possible, it is preferred to run the cables inside the building (shortest distance between two points) but this is not always possible due to the existence of fire walls. The temporary nature of the cable installations makes it impractical to penetrate the fire wall in a compliant manner each time a broadcast is performed.

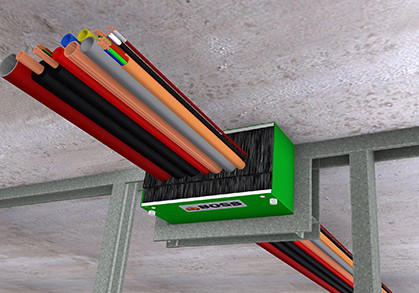

Concept Solution using the BOSS FyreBox Range of Cable Transits

The concept of using a permanently installed fire stop solution for temporary cable bundle applications was initiated. The Boss Fyrebox was considered due to its construction and functionality. When the box is installed at floor level, it creates a 'tunnel' for the cables to be run through the fire wall. When the cables are removed, the functionality returns to that of a blank seal. The integrity of the fire wall would be maintained irrespective of the presence of cable bundles.

The unique smoke brushes on the FyreBox allow for a smoke seal to be created prior to the heat activation of the intumescent material within the box.

The high pressure intumescent located inside the box provides 120 minutes integrity rating. Tested to AS1530.4 a FRR -/120/120 on multiple services — including metal sprinkler pipes of 38mm diameter, copper pipes with insulation (AC pair-coil), a range of plastic pipes and cables (power and data) using the P40Mak Wrap to 300mm either side of the box around all services — provides an insulation rating of up to 120 minutes.

Consultation Process

While the concept appeared to be sound, a coordinated consultation process was required to confirm the practicality of the installation and the repeated use of the transit.

The economic benefits of employing the concept became evident firstly from the facility management perspective (operations budget over time) and secondly from the construction company (cost of supply and ease of installation).

After agreement was reached with the broadcaster, the facility management team and the construction company, the developer commissioned a fire engineer to do an assessment of the product in this specific application to ensure compliance.

Learnings from this experience include:

- Approach the challenge with an open mind

- Be willing to consider new technologies

- Share the ideas/concepts with other stakeholders for their opinions

- Consider the technical capabilities and limitations of the device

- Base early assumptions on available compliance reports

- Be prepared to seek professional advice when appropriate

- The suppliers and manufacturers are a source of information not fully utilised

- Innovation often comes about as a result of asking questions

Collaborative Consultation Results In Innovation

This is yet another example of what can be achieved through a collaborative approach to addressing a challenge. We are all too often limited in our thinking by previous (negative) experience and a lack of specialist knowledge.

We at Potters encourage architects, designers and the professions to engage with us as early as the concept stage of a project to discuss the numerous aspects of passive fire protection on building projects.

We may not have all the answers, but can certainly make a constructive and innovative contribution to the collaboration process.

Most Popular

Most Popular Popular Products

Popular Products