A stunning residential property overlooking Lake Wakatipu was in its early stages of a complete renovation when the main contractor discovered the disastrous state of the building’s roof structure when removing the existing steel roof. The old steel roof needed to be replaced due to general wear and tear. It was long past its prime and was leaking, but when the material was removed, it exposed the decayed structure and an assortment of spacings between purlins; ranging from between 600-900mm to 1200mm.

Unfortunately, it was at this point, where the roof renovation graduated from just replacing the old roof cladding, to the need for a whole new structure which would include a new substrate, and brand-new waterproofing material.

The homeowners decided that since they would be paying for a new roof structure, they may as well go the extra mile, and invest in a warm roof system. The challenge they had was that they still wanted to maintain the metal roof look due to the existing aesthetics of their home.

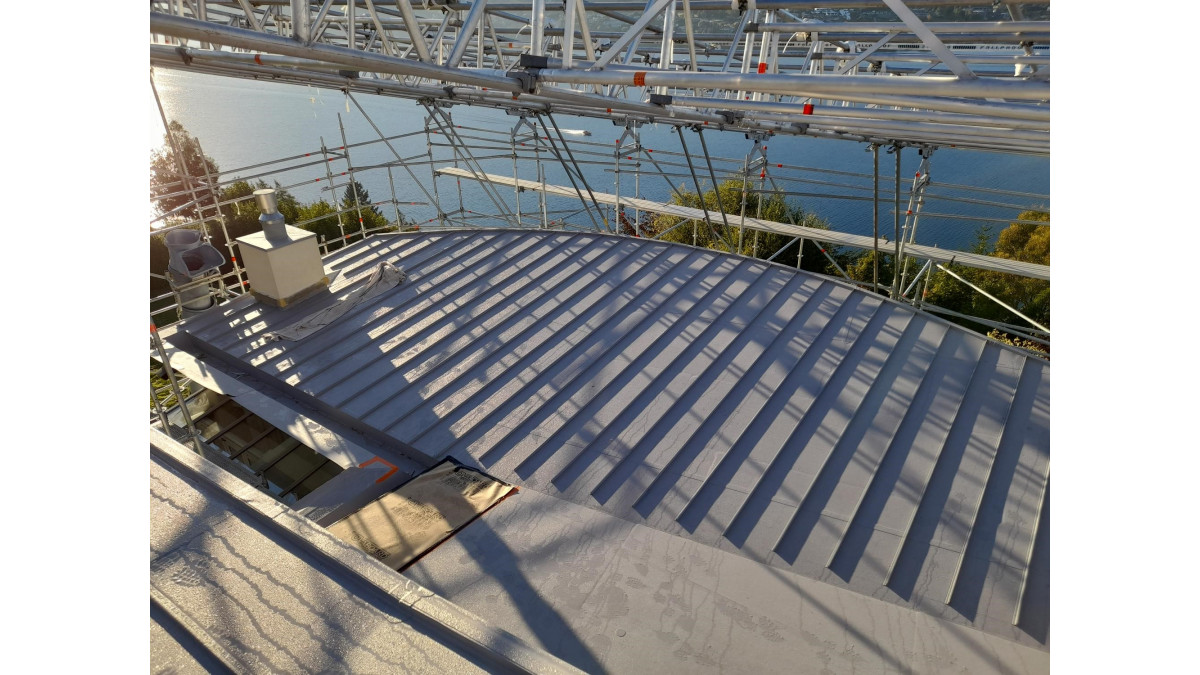

With advice from a Viking Approved Applicator, the recommendation was made to install a Viking WarmRoof using Viking Enviroclad as the waterproofing membrane due to its compatibility with a proprietary weldable rib accessory — exclusive to Viking Roofspec, which resembles the standing seam of a metal tray roof.

The renovation started with the reconstruction of the structure using 17mm CCA treated plywood supported by rafters secured consistently at 600mm centres which was sloped to form the fall of the roof, meeting minimum pitch requirements of two degrees. Seeing the home is located in Climate Zone 3, a vapour barrier was installed on the plywood (underneath the insulation panels). Parapets were then increased in height to accommodate the thickness of the warm roof’s 100mm polyiso insulation panels. The roof has a curved parapet, requiring a lot of care and extra time to shape the insulation board and then tastefully install the sheet membrane over the curve.

This shape then also poised a challenge for the weldable ribs as the installers had to calculate precisely where the lines would lie; cutting the ends of the ribs to sit along the curve.

Towards the end of the project, the builder decided to install skylights within the warm roof system, meaning the Viking licensed installers had to cut and remove some of the polyiso panels so the skylight upstands could be installed onto the substrate and then dressed with vapour barrier — keeping it continuous. Water diverters were also created as best practice to promote flow away from the skylight.

The homeowners and the builder are extremely impressed with the solution Viking and the Approved Applicator came up with to meet the unique requirements of this roof reconstruction. It is a beautiful looking roof that functions as an insulator, potable water collector and it provides a stylish look to the building’s exterior.

Although the Viking Approved Applicator faced some very unpredictable weather challenges, the homeowners and architect are extremely happy with the exceptionally clean finish and are even happier that it was completed at half the cost of a new standing seam zinc roof.

New Products

New Products

Popular Products from Viking Roofspec

Popular Products from Viking Roofspec

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts