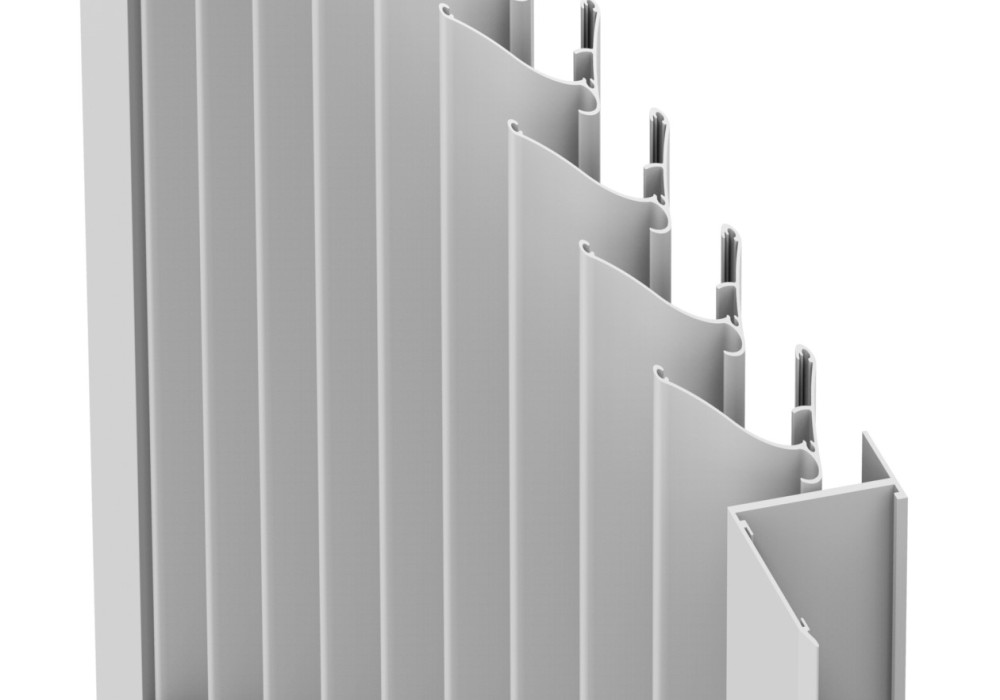

Traditionally, ventilation louvres have been constructed with horizontally oriented blades. No matter the type of louvre — whether it be single bank, double bank, triple bank, drainable, non-drainable, screening, acoustic — you name it, the blades have been set horizontally. However, with modern architecture being no respecter of such deep-set traditions, we have begun to see an increasing call for louvres with vertical blades.

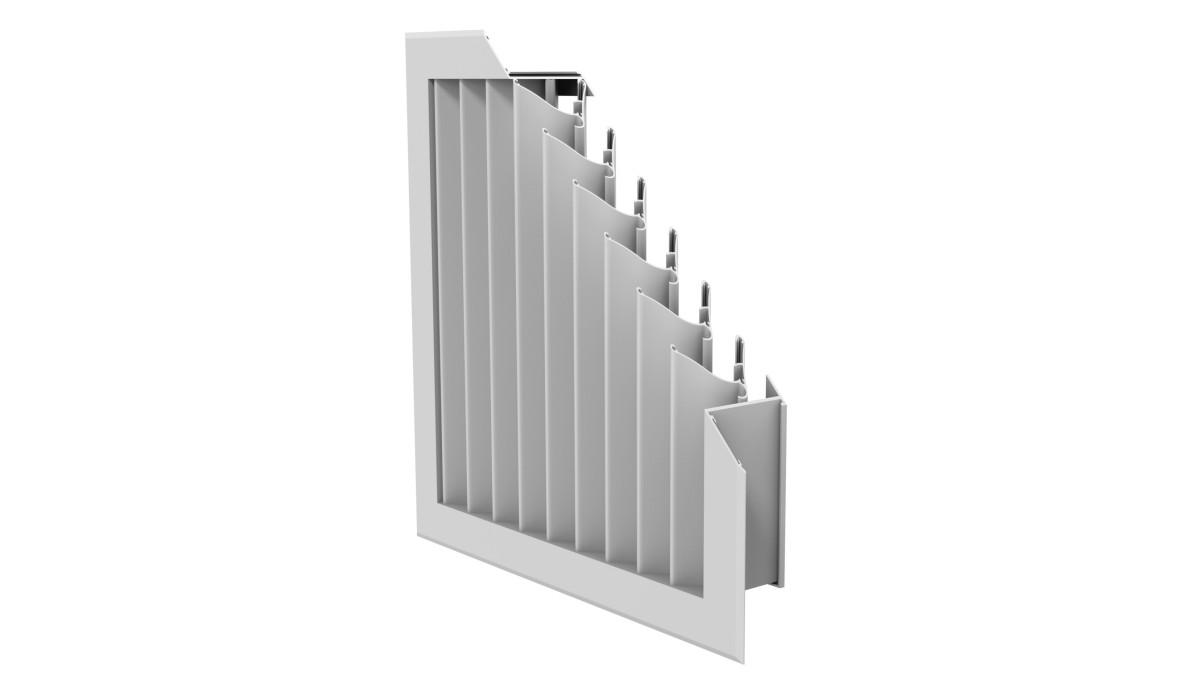

In response to this demand, Ventüer has developed a completely new double-bank vertical blade system: the VL-VF2.

With considerable time spent in the development of this system, including extensive CFD analysis and wind tunnel testing of prototypes, Ventüer had high hopes for the performance results of the final product. And the independent BS/EN:13030 performance testing didn’t disappoint: the VL-VF2 has certified Class A rain defence up to 3.5m/s intake velocity and an aerodynamic performance of Class 3.

To explain what this classification means: during the BS/EN:13030 testing procedure, air is driven at the face of the louvre panel by fan driven wind simulation equipment whilst nozzles spray water parallel to the airstream, simulating a 75mm/hour rainfall with 13 metres/second (47 km/h) wind. A second fan draws air through the louvre (simulating the intake of an HVAC system) at progressively higher velocities up to a maximum of 3.5 metres/second.

To achieve a “Class A” rain defence rating, a louvre must allow no more than 1% of the simulated rain to enter between the blades. The VL-VF2 achieved this by a very comfortable margin: at 3.5 metres/second intake velocity it is still 99.7% effective (i.e. only 0.3% of the water was getting between the blades).**

The VL-VF2 also has great aerodynamic performance, with a low pressure loss that is comparable to many single-bank (and much less weather-resistant) louvres. This means that there is less load on the mechanical plant, with the fans using less energy to draw air into the HVAC system.

And to cap it off, the system is only 100mm deep, meaning that it fits easily within standard window joinery and façade cladding systems. Constructed entirely from extruded aluminium, and available with flanged and channel perimeter frame options, the VL-VF2 can be easily integrated with any NZ façade system.

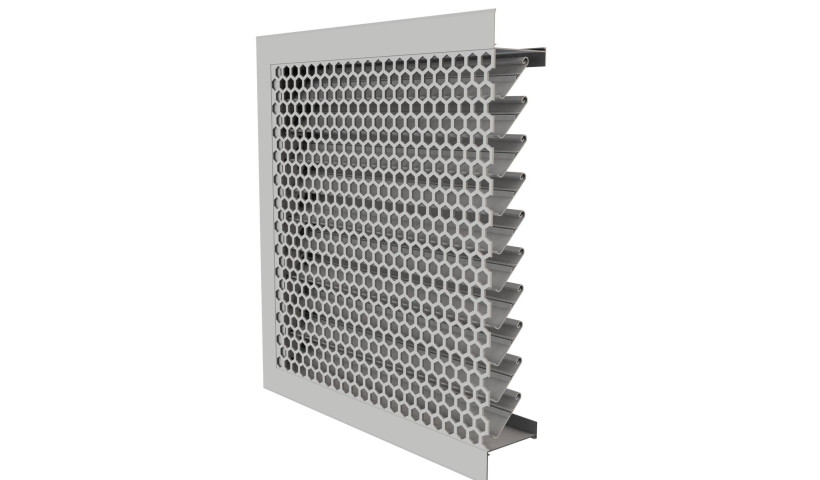

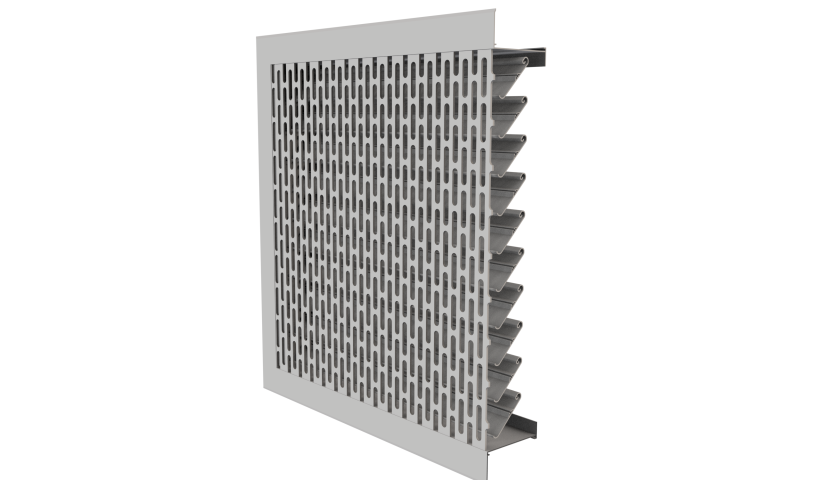

Standard ancillaries include optional bird mesh and insect screens to the rear of the louvre.

** Precautionary note: it should be noted that field conditions are sometimes more extreme than the BS/EN:13030 test, and that when exposed to very heavy rain and very high wind speeds more water may penetrate the louvre than is demonstrated by the test procedure. Please contact Ventüer to discuss project-specific applications.

New Products

New Products

Popular Products from Ventüer

Popular Products from Ventüer

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts