Noggings are horizontal members which run parallel with the top and bottom tracks and are typically installed in the centre of a steel stud wall. Noggings are required for various reasons, but most importantly, noggings provide the means for compliance with the National Construction Code (NCC).

Noggings help achieve compliance with NCC fire-rated wall requirements

The NCC addresses fire-resistance requirements of lightweight construction in Specification C1.8 Clause 3.4 (b) which states that fire-rated internal or external walls are to be subjected to a static uniformly distributed load test of 0.25kPa.

Rondo includes noggings, as required, in fire-rated walls lined one side designs to ensure that they:

- Have the structural adequacy to meet the BCA Specification C1.8 requirements

- Comply with the fire tested system

Noggings assist in compliance with NCC structural requirements

The NCC addresses structural adequacy requirements of lightweight construction in Section B. Within this part of the NCC, the minimum design actions to be considered are specified, and include amongst others wind and seismic actions.

Rondo includes noggings, as required, in their lightweight construction designs to ensure that they have the structural adequacy to meet the NCC Section B compliance requirements.

Noggings provide for more efficient designs

The use of Noggings reduces the unrestrained (torsional/ flexural-torsional) length in a Steel Stud Wall. The greater the unrestrained length, the less efficient the wall design becomes.

For example;

- Wall A: Has no nogging installed mid-height. The wall studs are 64mm x 0.75bmt and are installed at 600 centres, with 0.375 kPa ultimate pressure and one layer of 13mm plasterboard on one side only– the maximum wall height that can be achieved is 2300mm.

- Wall B: Has no nogging installed mid-height. The wall studs are 64mm x 0.75bmt and are installed at 450 centres, with 0.375 kPa ultimate pressure and one layer of 13mm plasterboard on one side only– the maximum wall height that can be achieved is 2801mm.

- Wall C: Has one nogging installed mid-height. The wall studs are 64mm x 0.75bmt and are installed at 600 centres, with 0.375 kPa ultimate pressure and one layer of 13mm plasterboard on one side only – the maximum wall height that can be achieved is 3050mm.

The most efficient wall in this scenario is Wall C as it achieves a greater wall height than both Wall A and B, and there are also fewer Studs to install than Wall B, reducing both material and labour costs. The above analysis has been checked in accordance with AS/NZS4600 Cold-formed steel structures code.

Noggings can improve the quality of the finish

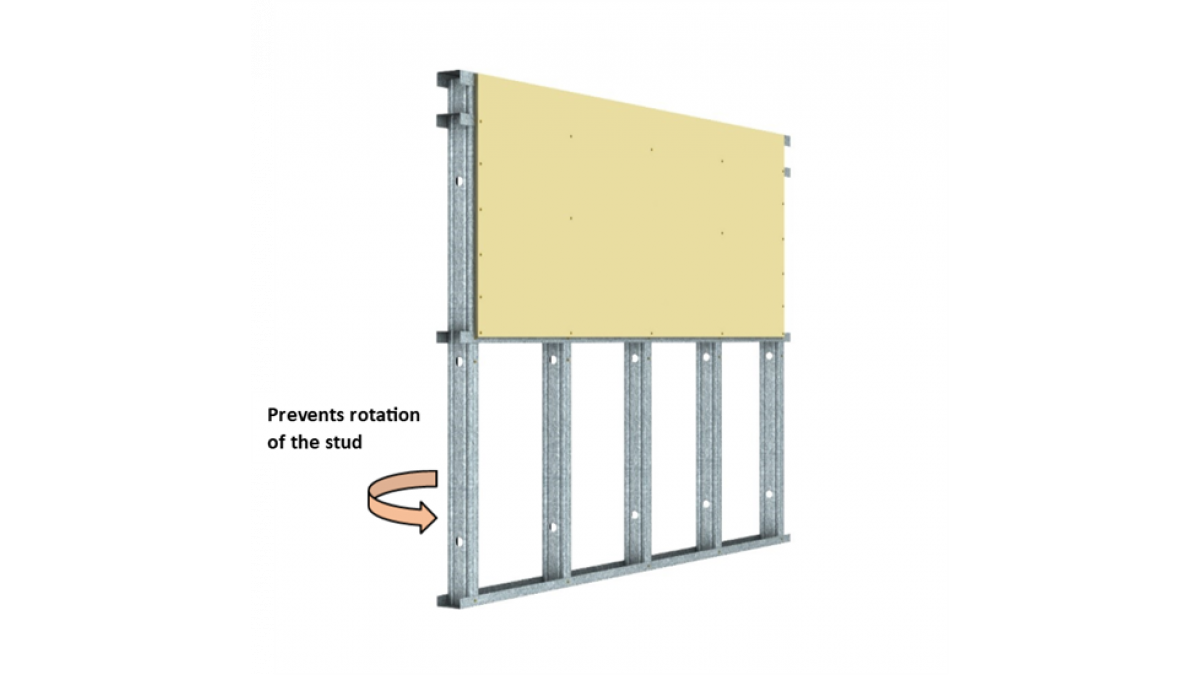

Stud rotation can be a problem, outside of structural adequacy and NCC compliance as well. Without the nogging, there is a greater chance of the wall studs rotating and this can cause plasterboard misalignment and potentially cracking of the plasterboard. Getting called back to a job where the plasterboard walls have cracked is costly and can also damage the reputation of the construction team.

Noggings can improve construction times

When lining a wall on one side only, the studs can rotate during the installation of the plasterboard. This can lead to quality problems such as uneven board set joints, misalignment of the framing with the board edges, plumb of the wall and the like.

By installing one row of nogging halfway up the wall, particularly when the wall height exceeds about 4m, the studs are kept aligned, set-out is maintained because the noggings are precision manufactured and the studs remain square to one another. This can speed up the installation of the plasterboard as installers don’t need to constantly correct the position or rotation of the studs as they fix the linings in place.

New Products

New Products

Popular Products from Rondo Building Services

Popular Products from Rondo Building Services

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts