Designed and developed by the Rockcote Resene Technical Team over the past two years, it addresses many if not all the issues faced by the plastering industry.

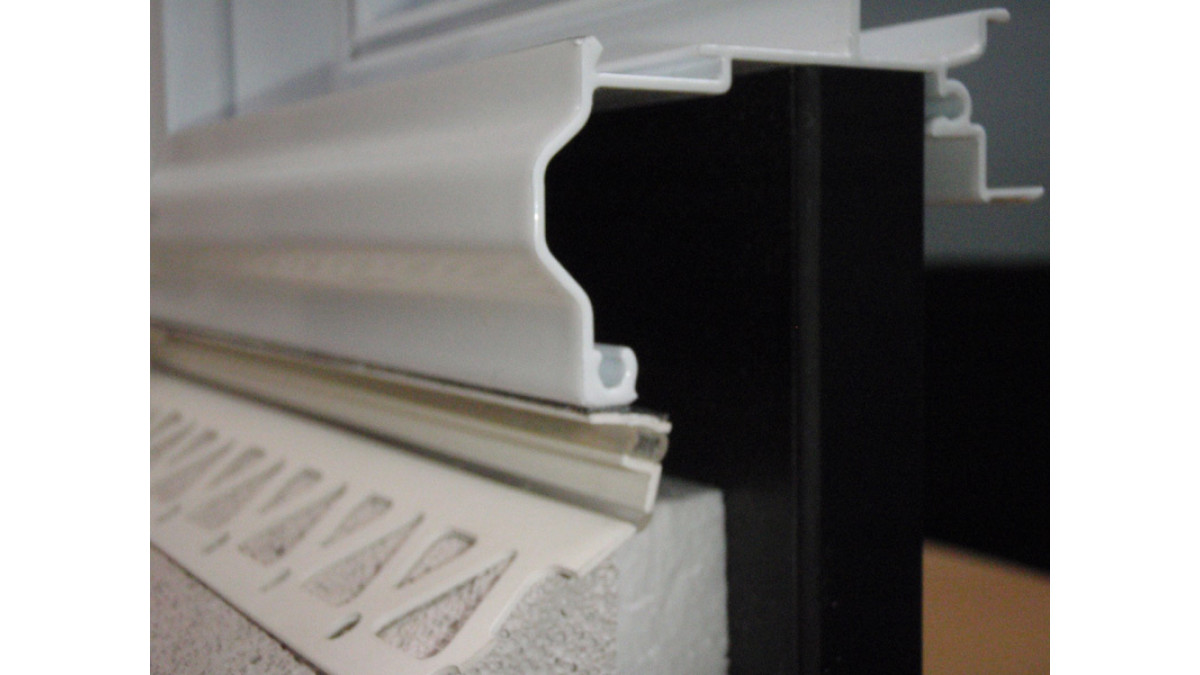

Multiple Cladding Junctions

Attaches to prepared, colour steel, zincalume, powder coated aluminium, fibre cement sheet, glass, wood and most other smooth painted surfaces.

Installation

Fast, easy, and accurate installation via the permanent bonding VHB adhesive.

Cost Efficient

Eliminates the requirement for assorted jamb and sill flashings for different systems, eliminates wastage, and dead stock.

Reduction in uPVC

Minimises uPVC thermal stress and resultant hairline cracking of coatings.

No Length Limit

The flashing can be butt joined to eliminate wastage.

Flexible Joint

Multiple co-extruded rubber joints allow for dissimilar substrate movement.

Flexible 'Elbow' Joint

Co-extruded rubber 'elbow' allows multiple angles to be achieved, ie sills, raking soffits etc.

Plaster Clearance

6mm primary connector leg allows for ample clearance when plastering to ensure no plaster contacts the adjacent substrate.

Pressure Equalisation Chamber

If the first co-extruded rubber membrane is broken the second layer remains intact to resist moisture penetration.

Rockcote GreenSite Approved Component

- Minimises waste during construction process / flashing can be joined.

- Reduces uPVC material required to achieve an equivilent flashing -- one flashing replaces 9 current flashings.

- BRANZ tested and passed to the E2 VM1 Weathertightness test criteria, and is designed and made in New Zealand.

New Products

New Products

Popular Products from Resene Construction Systems

Popular Products from Resene Construction Systems

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts