The challenge

The 90 Devonport Road project represented a significant opportunity and challenge: constructing New Zealand’s largest mass timber office building while meeting sustainability, efficiency, quality, and carbon reduction targets. With an eight-storey structure primarily featuring Cross-Laminated Timber (CLT), the project had high expectations for precision, timely delivery, and environmental leadership.

Red Stag TimberLab’s involvement

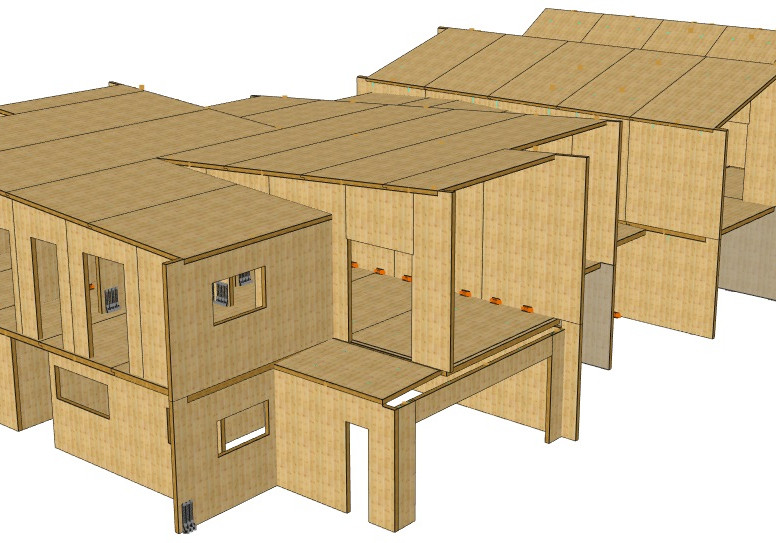

Red Stag TimberLab (RSTL) supplied over 3000m³ of CLT for floors, walls, roofs, and prefabricated stairs. The RSTL team provided consultation and design support with Early Contractor Involvement (ECI), to develop optimised CLT solutions tailored to the project’s requirements.

A meticulously executed 3D modelling process along with the latest CNC technology allowed RSTL to manufacture CLT elements to high precision. A total of 934 individual elements were manufactured and installed with speed and accuracy. RSTL’s digital fabrication process ensured a streamlined, just-in-time delivery that helped the construction stage stay on track without needing additional storage or material protection contingencies on-site, underpinning the project’s efficiency and minimising disruption during construction.

“LT McGuinness contracted Red Stag to provide the CLT walls and floor panels for the 90 Devonport Road project in Tauranga. The detailed shop drawing process and delivery schedule coordination enabled our team to confidently proceed with a just-in-time delivery model. The product quality allowed us to exceed the programmed installation timeframes for the entire build, creating advantages to commence the façade and fit-out ahead of schedule.” — Craig from LT McGuinness

Red Stag renewable energy

Red Stag’s self-sufficient renewable energy generation secures their position as one of the lowest-carbon CLT supplier in New Zealand.

Bio-Fuel Energy: Red Stag Timber utilises offcuts from sawing and planning as a bio-fuel to generate electricity and provide thermal energy to dry timber. Red Stag Timber is also a net exporter of electricity to the national grid to help power New Zealand’s growing energy needs.

Thermal Energy: Wood waste is used as the energy source for the kiln drying of timber. The thermal energy required to kiln dry timber can exceed 85% of the energy usage for a modern sawmill. Utilising its own wood offcuts as an energy source ensures that both CO2 emissions and landfill disposal requirements are minimised.

Results

The CLT components showcased exceptional structural integrity, surpassing traditional construction materials in strength and resilience. By leveraging the latest digital CNC technology and prefabricated CLT solutions, the construction process at 90 Devonport Rd achieved notable efficiency gains, reducing labour costs and accelerating project timelines without compromising on quality.

The CLT in this project has sequestrated 2,213.4 tonnes of CO2-eq based on Red Stag’s Environmental Product Declaration (EPD) and third-party calculations, greatly reducing the carbon footprint, and reinforcing RSTL’s commitment to sustainable construction.

“Engaging with local industries to build the Tauranga City Council offices at 90 Devonport Road has been one of the great pleasures of this development. This was certainly the case with Red Stag TimberLab, who manufactured and delivered the CLT components from their plant in Rotorua. The efficiencies of CLT manufacture from RSTL enabled the build to stay on time, and we have no hesitation in working with RSTL again.” — Will Ellison, Developer at Willis Bond

90 Devonport Road Project Credits

Client: Tauranga City Council

Developer: Willis Bond

Builder: LT McGuinness

Architect: Warren & Mahoney

Structural Engineer: Dunning Thornton

Product: CLT

New Products

New Products

Popular Products from Red Stag TimberLab

Popular Products from Red Stag TimberLab

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts