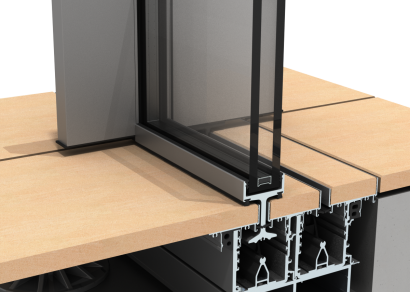

Qwickbuild decking sub-frame components are made from marine-grade, anodised, structural aluminium, with all accessories comprised out of stainless steel or GRP nylon. With the use of non-corrosive materials, Outdure has ensured that the Qwickbuild sub-frame won't be affected by moisture, like traditional timber materials.

Qwickbuild offers superior durability and dimensional stability and is able to span 200 per cent more than the equivalent sized timber. This eliminates up to 50 per cent of the required piles, plus it has the benefit to cantilever 50 per cent of its full span.

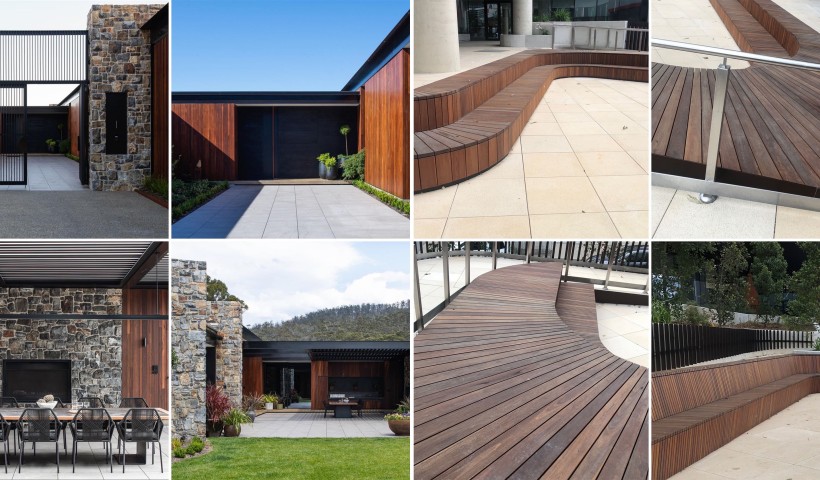

Qwickbuild is available in a variety of joist sizes specifically engineered for other Outdure products such as Ecodecking and Resortdeck – along with other hardwood decking timbers – and can support structural tiles. Qwickbuild is able to achieve a minimum height of 73mm to finished deck level with the use of Ecodecking. This is a perfect solution for when low height outdoor flooring is a requirement.

All Qwickbuild sub-frames are supplied as pre-fabricated panels, or cut to length as a kit-set. This is achieved due to the custom design service offered by Outdure to calculate the best post, bearer and joist layout for the specific scenario. The pre-fabricated Qwickbuild panels can easily be lifted by two people, and placed in position in the required location on site.

Qwickbuild and Ecodecking, used together, reduce installation deck construction by up to half of the usual time, because no fixing of the decking board is required. Qwickbuild is able to be installed over soil/dirt, unsightly cracked concrete, or the most uneven pavers plus, is also a 100 per cent compliant solution as a free standing substrate over water-proof membranes.

View animations of installations on timber piles, over soil and waterproof membranes, and structural tiles installed on a waterproof membrane. To find out more about Qwickbuild, visit Outdure's website.

Product News

Product News

Popular Products from Outdure

Popular Products from Outdure

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts