MAXRaft specialises in insulated concrete flooring systems designed to increase the performance of a building from the foundation up. These systems deliver excellent thermal performance and energy efficiency for a range of projects — from schools, hospitals and retirement villages, to social housing developments and stand-alone residential homes.

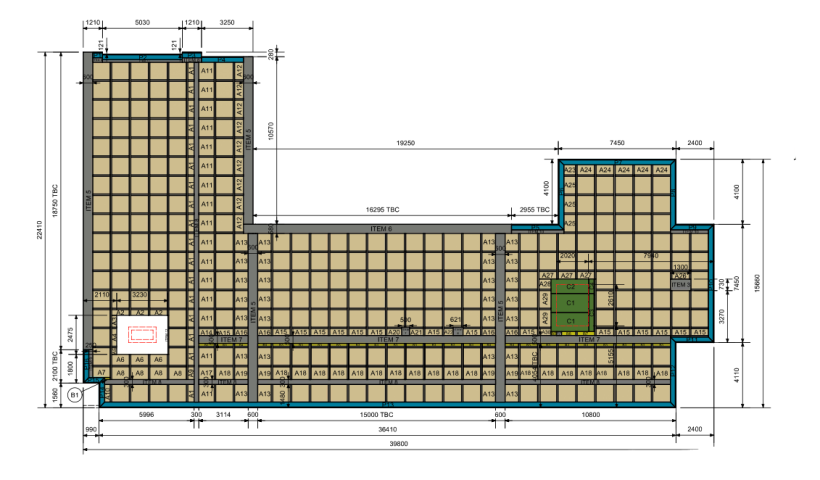

Designed to suit different ground conditions, the MAXSlab and MAXRaft systems feature pre-cut polystyrene components which are manufactured off-site and supplied with a panel plan to maximise on-site efficiency and minimise waste. Each component contains 15% recycled material and can be recycled at end of life.

The MAXSlab and MAXRaft systems are suitable for Homestar and Passive House designs and have exceeded the latest H1 requirements for over ten years, making them a reliable solution for meeting compliance and preventing heat loss through the foundation.

MAXSlab — for good ground conditions

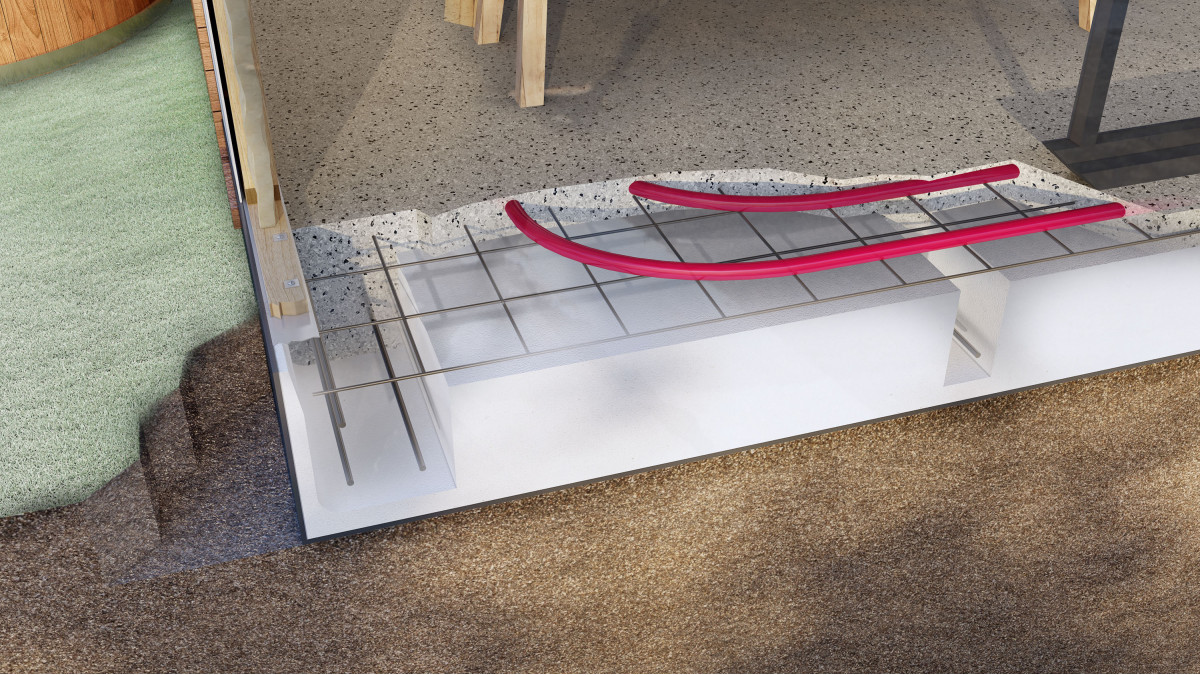

The MAXSlab insulated flooring system is ideal for projects where ground conditions meet the definition of ‘good ground’ as per NZS 3604. The system features three insulation components which work together to provide a continuous insulating layer beneath the slab and to the exterior perimeter surfaces:

Perimeter footings or slab edge insulation create a thermal break, reducing heat loss from the perimeter (where up to 80% of heat loss typically occurs)

Load bearing thickenings support load bearing walls, while maintaining a complete thermal envelope around the foundation

Polystyrene infill ensures the floor slab is properly insulated and a thermal break is maintained throughout

Installed on a damp proof membrane, the system provides an R-value of R-2.6 to R-5.6.

MAXRaft — for less stable ground

Engineered to be seismically stronger in earthquake conditions compared to traditional concrete foundations, the MAXRaft system is suitable for constructing insulated slabs on less stable ground, including projects with soft ground, expansive soils or where piles are required, as well as TC2 type ground found in Christchurch.

MAXRaft features a similar three-layer build-up to the MAXSlab system, with one key difference in the design of the infill area, which features stiffened ribs throughout the floor to maintain a thermal break around the foundation — effectively preventing the heat loss to the ground between ribs which often occurs in traditional waffle floors.

The MAXRaft system provides a foundation R-value of R-1.9 to R-5.6.

Meet H1 compliance with MAXRaft

The R-values achieved with the MAXSlab and MAXRaft systems are dependent on project-specific design and area/perimeter ratio. Both the MAXSlab and MAXSlab systems can also work in conjunction with Underfloor Heating where a minimum of R3 is required. The MAXRaft team can work with you to meet and exceed the R-values required for your design.

New Products

New Products

Popular Products from MAXRaft

Popular Products from MAXRaft

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts