In recent years, there has been a significant shift towards prefabricated and modular construction to combat the ever-increasing challenges the construction industry faces including trade availability, safety, quality, speed, and construction landfill waste.

This form of construction is becoming increasingly mainstream globally. Moreover, the New Zealand government has implemented the recent H1 code construction changes and initiatives to help drive the uptake of offsite prefabrication and modular construction.

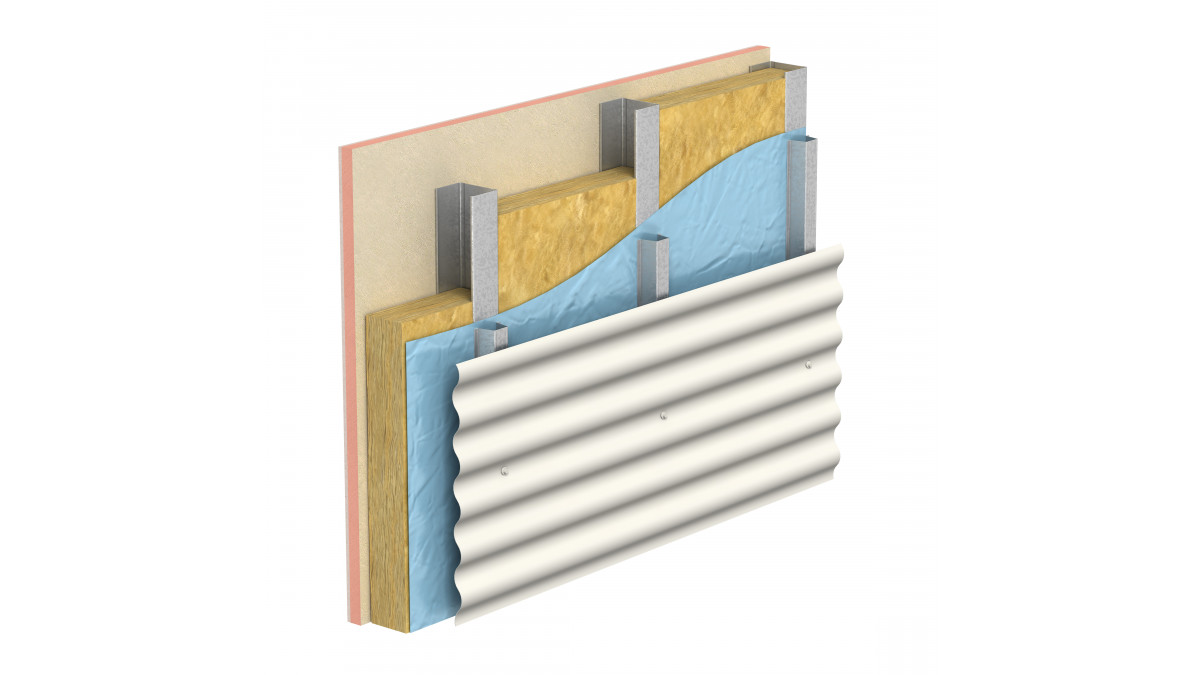

Prefab or modular constructed buildings incorporate metal framing and insulation to comply with the NZBC.

All materials will conduct heat to some extent, but certain materials such as metals will transmit large quantities of heat quicker. Modular buildings rely heavily on metal frames, which can lead to poor thermal performance due to thermal bridging. As heat takes the path of least resistance, a significant amount of heat loss or gain occurs through a metal frame. Consequently, the building suffers from a lower thermal performance and in turn becomes a less energy-efficient building.

Not only metal but timber frames are responsible for thermal bridging too. The recent survey by BRANZ and Beacon Pathway shows that timber frame construction, also fabricated off-site, has an average of 34% thermal bridging through framing. That means that prefabricated wall frames for houses insulated between the framing elements only, do not meet the construction code requirements.

Several factors affect the choice of insulation, including maximising cost efficiency, customer outcomes and material properties and orientation that meet NZBC compliance.

Using a modern continuous insulation material, such as Kooltherm, can provide a better solution for prefab and modular structures than conventional framed segments. This solution slows the movement of heat through building elements by separating the bridging points in a continuous form. It can be installed quickly on either the internal or external side of the frame, delivering higher performance outcomes and thermal resistance and a thinner wall footprint in many cases.

The use of metal in modular buildings can also lead to an increased risk of condensation, especially if the building is used in colder climates. Condensation may occur as a result of insulation only being installed between the stud of a building, lowering its thermal effectiveness and reducing the temperature of materials inside the walls. This also extends to the internal lining. When insulation is only installed between the studs, it is common for cold spots to occur where the plasterboard has been fixed to the studs. This can lead to damp spots as a result of condensation, also known as ghosting. The installation of a continuous layer of insulation next to a frame keeps the temperature of the frame regulated, making it less likely for the temperature to fall below the dew point, reducing the risk of mould and condensation.

As these buildings are partially or fully constructed off-site and then transported to their destination, strict requirements are in place when considering space. Along with needing to fit perfectly together, it is essential for these buildings to be easily transportable, ensuring costs are kept to a minimum. Therefore, the width of these buildings must fall under permitted limits dictated by transit rules. Overstepping these limits can result in the requirement of a special transit permit and potential road closures, both of which increase construction costs.

Using a high performance insulation product with a slim profile means building depth doesn’t need to be increased to fit thicker bulk fibre insulation, allowing frame size to be maintained and eliminating future transport issues.

Prefab buildings are used frequently when constructing buildings, such as hospitals and schools. As these buildings are considered special use, they must achieve a higher level of energy efficiency whilst providing a consistent comfort for all occupants. Insulation plays an important role when thermal comfort is considered, therefore it is vital to select the right insulation material.

As modular buildings are designed for use and re-use across New Zealand, a range of different weather extremes and the six new climate zones must be considered. Using an insulation material that is adaptable and performs consistently at a high level, regardless of the climate outside the building envelope, is essential.

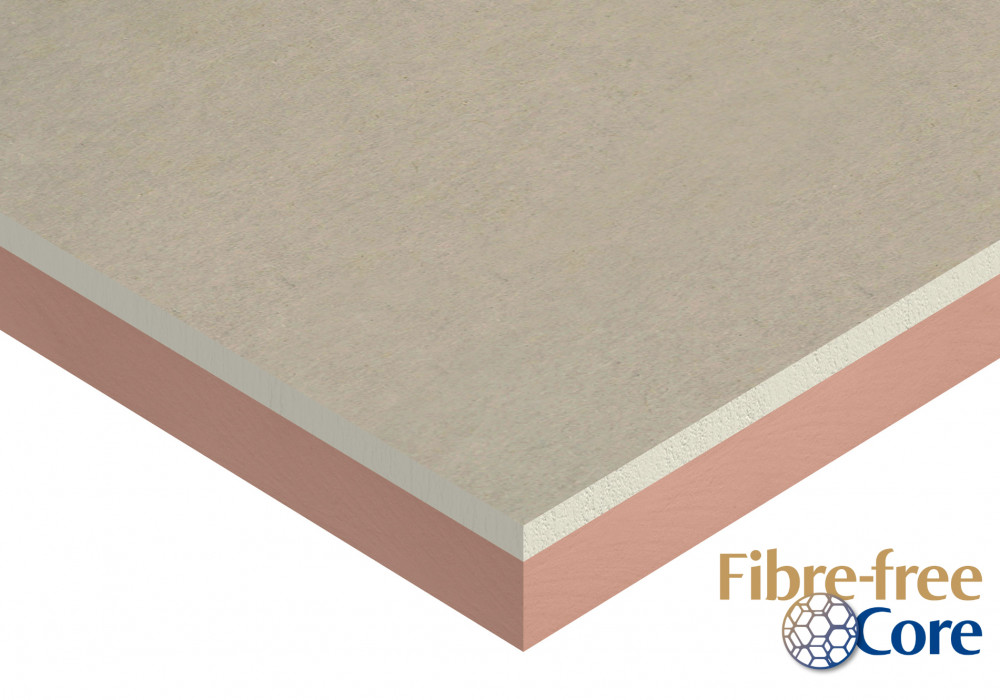

Kingspan Kooltherm insulation offers the perfect solution for modular building. It provides a continuous layer of insulation eliminating the effects of thermal bridging and reduces the likelihood of condensation allowing for thinner construction profiles. Moreover the Kooltherm range is a high performing thermoset phenolic insulation with a fibre-free core making it ideal for roof, wall and floor applications. Being a thermoset material, it boasts exceptional fire performance, demonstrating low fire spread and smoke emission.

To browse the full Kooltherm range, visit the Kingspan Insulation website or get in touch with our Technical Services team who will be happy to help you find the most suitable insulation for your project — call 0800 123 231 or email [email protected].

New Products

New Products

Popular Products from Kingspan Thermakraft

Popular Products from Kingspan Thermakraft Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts