With intensification in New Zealand's major cities, changes are being made to the way buildings are designed to maximise space. To increase useful space in a building there is a move towards lower pitch roofs (under 12.5°). What does this move to a lower pitch roof mean for roofing design? Why does the pitch of the roof impact the design?

Roof pitch is integral to moving water off a roof quickly to prevent ingress into the building. The minimum pitch of a roofing profile is designed to prevent water leakage through the side laps in heavy rain when the profile may be at full capacity with water and there is wind pushing the water back up the profile, stopping the flow to the gutter.

Prior to the 1970's many metal roofing profiles were being laid as low as 1° to 1.5° pitch to suit the style of buildings. However, after seeing issues of water ponding as roofs settle over time, the metal roofing industry changed this in the 1970's to a minimum pitch of 3° for all coated steel and aluminium products. Raising the minimum roof pitch of all coated steel and aluminium products gives enough tolerance to avoid roof deterioration and ensure the roof dries, meeting the minimum 15 year durability requirement of the NZBC.

If site height restrictions allow, it is always recommended to lift the minimum pitch up to 3.5° to allow for roof movement from long term dead loads such as snow. Dimond also recommends increasing the roof pitch by 0.5° on long roof runs over 20m to ensure the best water carrying capacity. This increase in roof pitch also aids the natural self-cleaning of the roof, increasing the roof's life and reducing the manual washing required to meet warranty conditions.

When designing a low pitch roof, remember that minimum pitch is impacted by:

- Roofing profile rib height

- The width of the pan

- The rainfall in the area

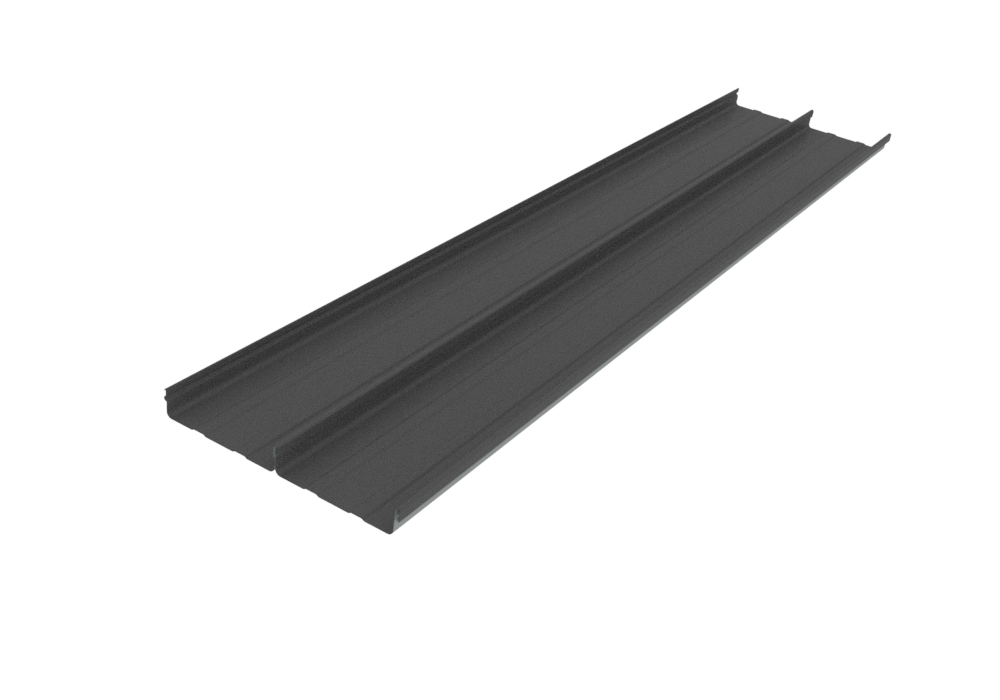

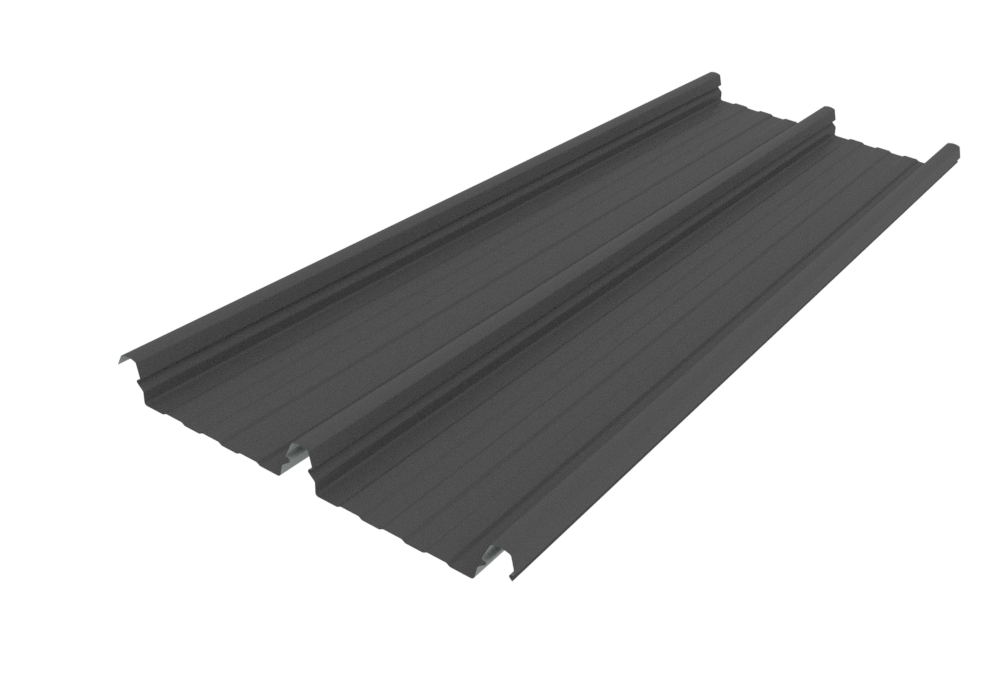

All Dimond profiles are suitable for low pitch roofs under 12.5° and range from a minimum pitch of 3° to 8°, with a capillary groove or gap in the under rib to reduce leakage through the side lap.

When designing for low pitched roofs in heavy rain areas, Dimondek 400 and Dimondek 630 are excellent. Both profiles have a large water carrying capacity, are concealed clip — reducing the places water can enter the roof cavity, and can be roll formed onsite to avoid steps or end lapping, thereby reducing the risk of water penetration.

New Products

New Products

Popular Products from Dimond Roofing

Popular Products from Dimond Roofing

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts