Other common names for fibreglass are glass-reinforced plastic (GRP), glass-fiber reinforced plastic (GFRP) or GFK (from German: Glasfaserverstärkter Kunststoff). It was invented in 1938 to be used as a material to provide insulation, but it was soon shown to have wider and far superior properties. The combination of glass with plastic polyester resins gives this remarkable product a stretchable and flexible strength combined with an ability to support heavy loads.

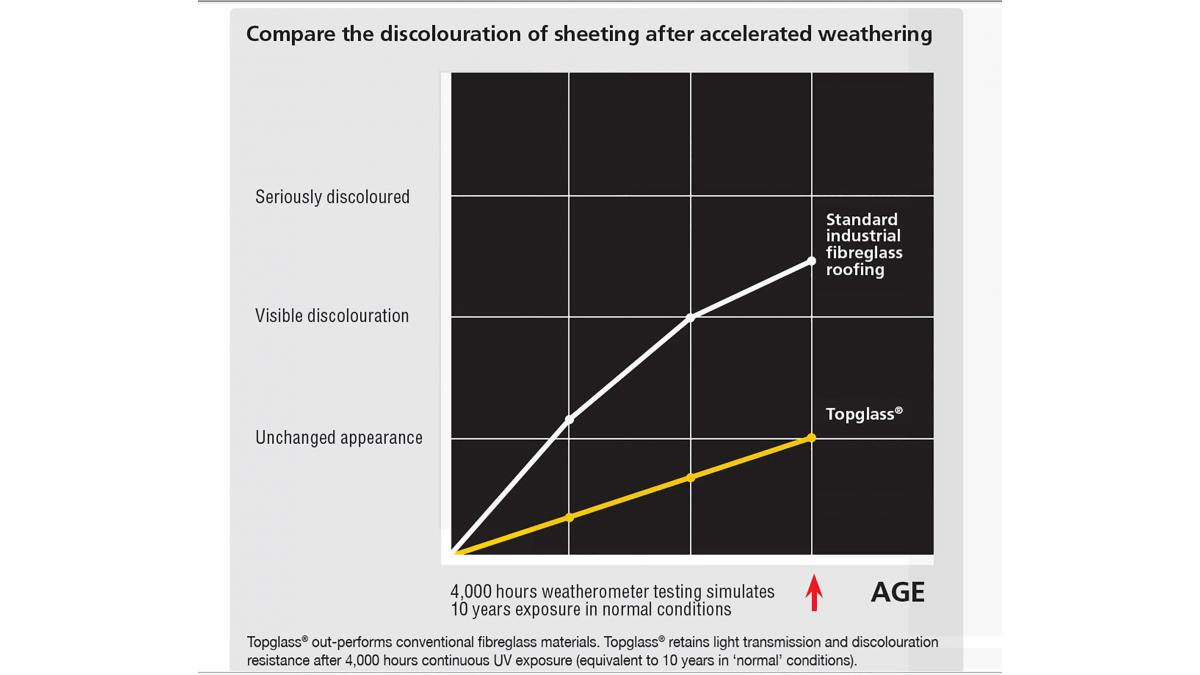

Alsynite One’s Topglass outperforms conventional fibreglass materials. Topglass retains light transmission and discolouration resistance after 4,000 hours continuous UV exposure (equivalent to 10 years in ‘normal’ conditions).

Among its other qualities, Alsynite's Topglass:

- Provides high-quality long-term natural light transmission

- Prevents water absorption and osmosis

- Retains its smooth finish for a greater period of time providing self-cleaning benefits

- Provides innovative product variations in meeting design criteria

- Is a cost-effective UV resistant translucent roof sheeting

- Has improved aesthetics, extreme clarity and improved strength

- Encompasses in-built NZA-5 UV inhibitors which prevent early degradation, yellowing and embrittlement of the sheet.

The construction of roofs made from Fibreglass Roofing Sheets is quick and the design and materials meet all building regulations. The sheets themselves are decorative and attractive in appearance.

Corrugated glass fibre roofs are especially useful for buildings that require a considerable amount of internal light. The clear nature of the GPR roof allows obscured light to flow through providing a bright atmosphere within the building itself.

It is a truly versatile substance and ideal for providing safe and secure covering for what can prove to be the most vulnerable region of a building.

New Products

New Products

Popular Products from Alsynite

Popular Products from Alsynite

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts