We were recently in the company of project managers, quantity surveyors and passive fire installers in a social environment. While all were from different companies, they were all very aware of the enigma that is passive fire.

The usual chest thumping took place with comparisons of the size of projects under management and the ability to deliver in time and the performance against budget.

The informal discussions that took place over the ensuing couple of hours provided some interesting insights. The perceptions of the percentage of the overall budget that should be allocated to the supply and installation of fire stopping on high density apartment projects were very diverse. As were the anecdotal references to completed project passive fire budget blow-outs.

While the project managers are concerned with getting the job done on time, the quantity surveyor's objective is to get the project over the line within budget. The firestopping installer is concerned with getting the job done right the first time and the building consent authority wants a building that complies with the NZ Building Code.

Perspective of the project manager

“I don’t want to have to justify budget blow-outs so wherever possible I spread the cost of labour for reworks and rectifications into all available cost centres." This comment had us considering how widespread this practice actually was.

Project managers, and the foremen on site, often have to get the sub-trades (passive fire installers) to propose compliant designs and system solutions for these reworks and rectifications and then provide a quote for the work. These are then dealt with as variation orders in terms of the project budget.

Where the trades — plumbing, electrical, mechanical services etc — have not “tagged-out” the supply and install of fire stopping on their scope of work, they often install compliant devices in a non-compliant manner. Fire stopping is, after all, not their core business.

The consequence of this lack of coordination between the trades and the sub-trades is that no one is able to accurately determine the actual cost to the project of passive fire.

Perspective of the quantity surveyor

“We encourage the trades to “tag fire stopping out” of their scope of work and pass the responsibility onto the project managers to manage the installation process on site.” When asked why a scope of work for fire stopping was not formulated in the same manner as would be the case for the electrician and plumber, there appeared to be a notion that the percentage of the overall budget allocated to fire stopping did not justify this.

This raises the question: “Is there a reasonable manner to more accurately determine the true cost of fire stopping?”

Consider the following list of “hidden” costs associated with not getting it right the first time:

- Cost of repeated construction monitoring

- Cost of repeated compliance inspections

- Cost of engagement of subject matter experts (designers, fire engineers etc.)

- Cost of site foremen’s time to research alternative solutions

- Cost of time spent gathering compliance data from manufacturers

- Cost of repeated consultations with designers, fire engineers and installers seeking agreement

- Cost of time labour spent off the tools waiting for decisions to be made

There is often no fire stopping cost centre setup in the project accounts and consequently many of the actual costs are not properly allocated by the administrators.

The procurement of additional fire stopping materials may be the only actual cost recorded.

Often the design of a compliant alternative solution (to rectify a non-compliant installation) would necessitate a substantial labour component with multiple phases of installation at the same penetration. The fire stopping sub-contractor may load the price when submitting a request for a variation order to cover the cost of labour to remove the non-compliant installation.

Perspective of the fire stopping contractor

The installation contractors offered insights into the different approaches taken by the main contractors as to how they record passive fire costs.

Some construction companies have a specific person (a foreman) responsible for the fire stopping on the project. This allows for more effective scheduling of trades and allows the fire stopping installer to have some input into the preparation of penetrations.

Others appear to “cross the bridge when they get to it”. Little planning or coordination of trades takes place and the fire stopping installer is often seen as the last resort.

The installers were quick to mention that a lot of the work was proposed as variation orders with approval being obtained before work commenced.

This is a reactive rather than proactive approach. There have been incidents where the design and specification had been signed off as a variation order, only to find the product, in the quantities required, were not available. This resulted in the entire process being repeated causing much frustration and delays.

In neither case is there a clearly defined manner of accurately determining the true cost of fire stopping on a project.

Perspective of the fire stopping product supplier

We need to be engaged at the concept design stage of each project.

We can add value to the project by providing insights into the design and timing of the incorporation of compliant fire stopping solutions.

Early consultation is the key to accurately determining the true cost of fire stopping on new builds and within the built environment.

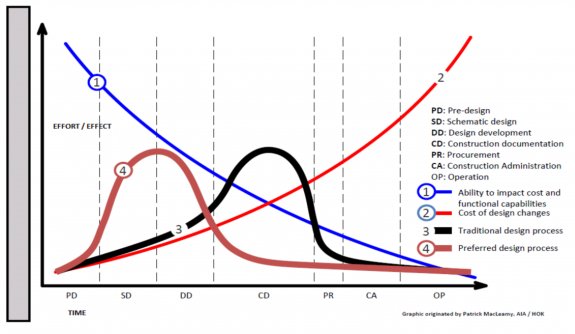

The MacLeamy curve indicates the Preferred Design Process to be at the “schematic design” stage of the process.

By incorporating “slots” into the concrete floor design — in collaboration with the structural engineer — to install compliant cable transit devices for cable trays and pipe runs etc, would reduce the risk of not getting it right the first time.

With the use of BIM modelling and Revit design, the layering of services in acute spaces is achievable and with compliant multi-service, single point of entry devices now available on the market, there is no reason why this technology should not be the preferred method of fire stopping.

This could be included in the PS2 submissions the building consent authority on new build projects.

This would eliminate the risk of non-compliance and all the associated direct and indirect costs involved with not accurately determining the true cost of fire stopping.

By building compliant fire stopping into the project plan as an overlapping activity with the major trades like plumbing and electrical, the issue of PS3 and PS4 would be straightforward.

The True Cost of Fire Stopping

A consensus was reached that not enough effort is put into understanding the processes and procedures of accurately recording the actual cost of fire stopping on site, when there is inadequate allocation of budget for fire stopping.

All the players can get the best result by involving the supplier early in the design phase of the project. There are reasonable ways to more accurately determine the true cost of fire stopping by making provision in the project plan and the project budget — by consulting with the supplier early in the design process. This is what is considered as being best practice in other parts of the world, so all we collectively need to do is talk to each other.

To secure a consultation with your Potter Interior systems passive fire account manager simply contact us at 0800 POTTERS.

Most Popular

Most Popular Popular Products

Popular Products