Until now, the NZBC has stated that nails are the only solution for weatherboard fixing. This system can be time-consuming with multiple steps for the builder, and comes with the inherent issues that nailed solutions often encounter (damage to the back of the board, and fastener pull as the board expands and contracts).

Now BRANZ has appraised the Quik Drive screw system and Simpson Strong-Tie Trim Head collated screws for weatherboard fixing.

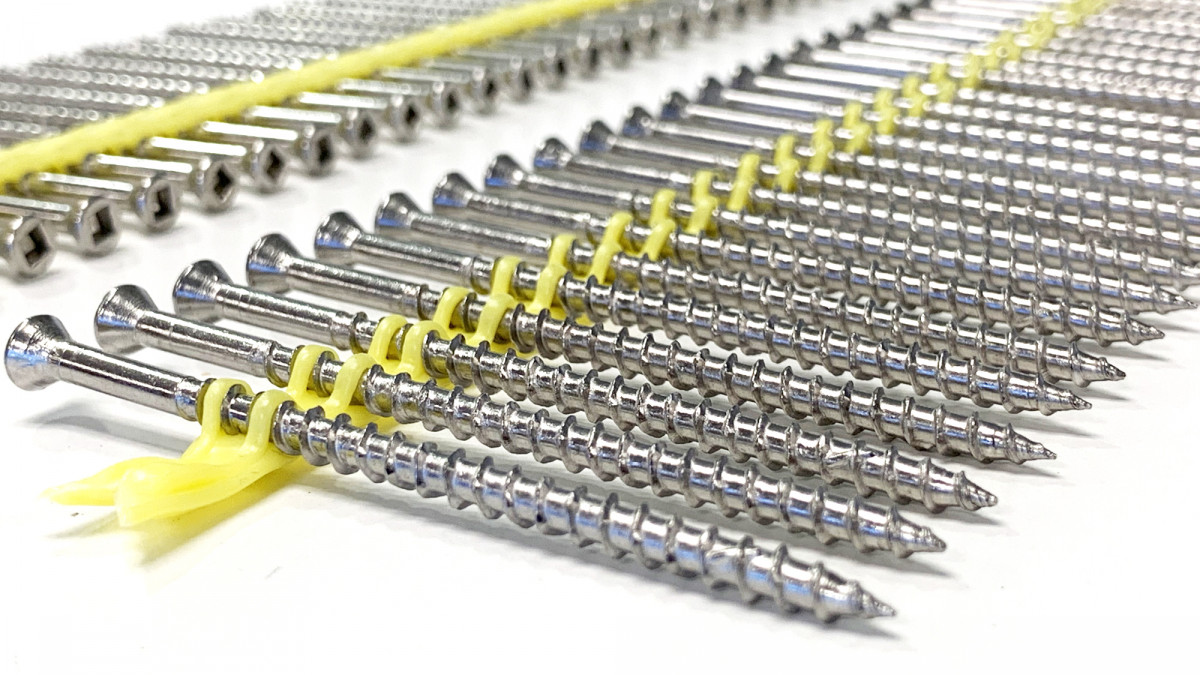

These 7G 305 grade stainless screws come in two lengths (65mm and 75mm) and install via the Quik Drive PRO300 screw gun. Not surprisingly, screw testing by BRANZ has revealed stronger hold than nails, which resists fastener pull out, making the structure stronger and reducing the risk of call-backs for the builder.

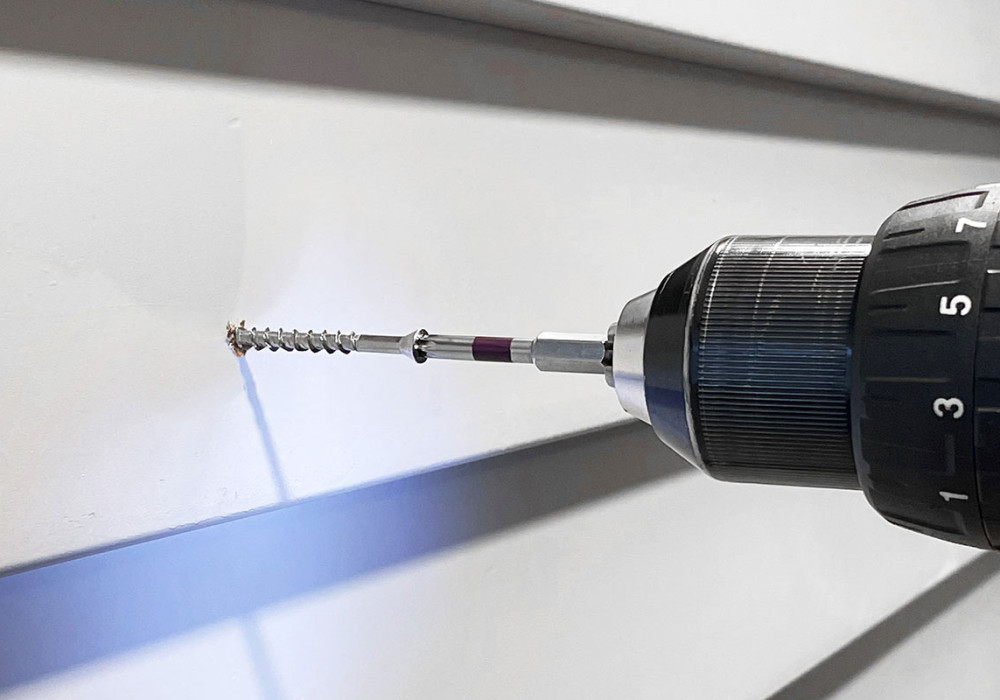

Installing these via the Quik Drive System allows the builder to accurately set and control countersink depth (no more running back through and punching nails), and the weatherboard clip removes the need to mark out the height and ensures the fastener never grabs the board below.

The trim head leaves a small hole for subsequent filling, and dramatically reduces damage in the back of the board meaning less risk of moisture ingress over time, making this the ideal solution for builders and cladding crews.

New Products

New Products

Popular Products from Simpson Strong-Tie

Popular Products from Simpson Strong-Tie

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts