When building a house overlooking Mangawhai’s stunning white sand dunes, a standard out-of-the-box build just isn’t going to cut it.

The owners wanted their new house to fit the beautiful Mangawhai setting and showcase stunning views on all sides. They worked with builder Peter Oakden to develop a plan for a unique home using natural materials, and designed to stand up to the harsh weather conditions that come with living by the sea.

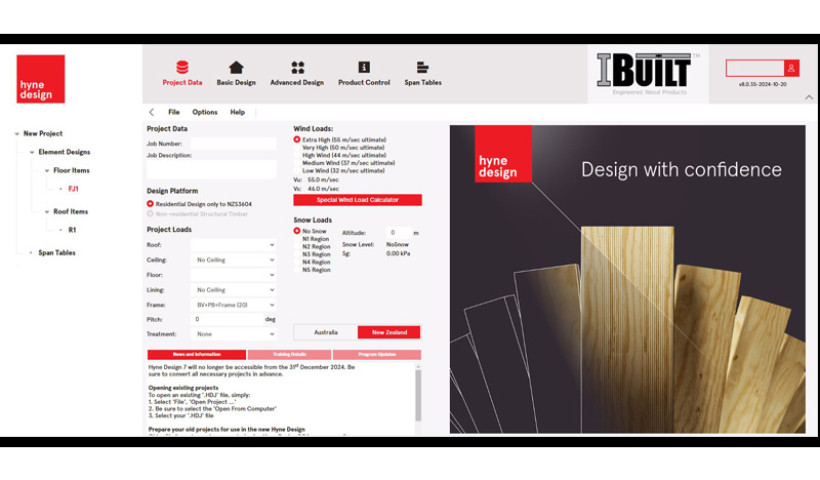

That’s where IBuilt’s Hyne Beam 21 came in. The high performance engineered hardwood was used for two huge internal roof beams that join external portals. Choosing the high-strength Hyne product gave the owners the uninterrupted views and durability they were looking for — and they look fantastic as well.

The owner explains: “The beams are absolutely stunning, as is the entire house. Driving up the road, the exterior of the house makes a very bold statement. It can be seen for miles around.”

Natural setting, natural materials

One of the key requirements for the build was that the new house needed to fit into the landscape. It also needed to be tough enough to stand up to the harsh winds, storms, and sea spray thrown at it from every direction.

That meant finding naturally strong, resilient materials — like wood. The builder and owners chose to go with natural wood for the exterior, in a range of timbers to suit.

Peter had seen a sample of the Hyne 21C hardwood product during a work presentation, and thought that it could be the ideal material for the house, performing as needed without compromising the aesthetic of his design. Hyne 21C is an engineered and glue-laminated wood product made of Australian hardwood, offering extremely high strength performance — in fact, it’s often used as a replacement for steel.

Peter says: “The beauty of the Hyne 21 was that it provided the strength and stability we were looking for, yet was dimensionally not excessive.”

Custom-made for a perfect fit

Ultimately, the Hyne engineered hardwood was used to create two huge custom internal beams that extend out of the house, and seven external ‘portals’ that extend to the ground in an inverted L shape. Project Engineer Stephen Orchard explains that the external beams are not actually structural portals, but give the building a “robust timber feel.”

The L joints are mitred internally with metal plates for strength, stability, and a clean finish, which made installation slightly more complicated. Builder Peter explains that it would have been tricky to do onsite. Working with the I-Built design team made it easier. The team worked with him to meet his design specifications and make sure the build went smoothly.

Peter says: “They were great to work with and very accommodating and helpful, not just producing the basic item but also preparing and mortising the knee joint, which would have been difficult to do onsite.”

Photos by Dan Stenhouse at Creative Lab

New Products

New Products

Popular Products from New Zealand Wood Products Ltd

Popular Products from New Zealand Wood Products Ltd

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts