Built by Mainzeal Property & Construction for Wintec (Waikato Institute of Technology) the carparking building just off Ward St flanks the main pedestrian entrance to the Wintec City Campus and therefore required special touches to ensure it added rather than subtracted from the streetscape.

Chow:Hill Architects decided to mask the northern wall with a translucent glazed façade that used the same design language as the main façade on the former campus library that sits nearby — a multi-level showcase of diagonal transoms and mullions that has earned the affectionate description "crazy glazing."

The window manufacturer was FIRST fabricator, Origin Windows Ltd, of Hamilton, and the glass supplier was Chesham Glass & Glazing. The façade project was one of the most technically demanding that Origin has been involved in and was a finalist in the 2011 Window Association of New Zealand Design Flair Awards.

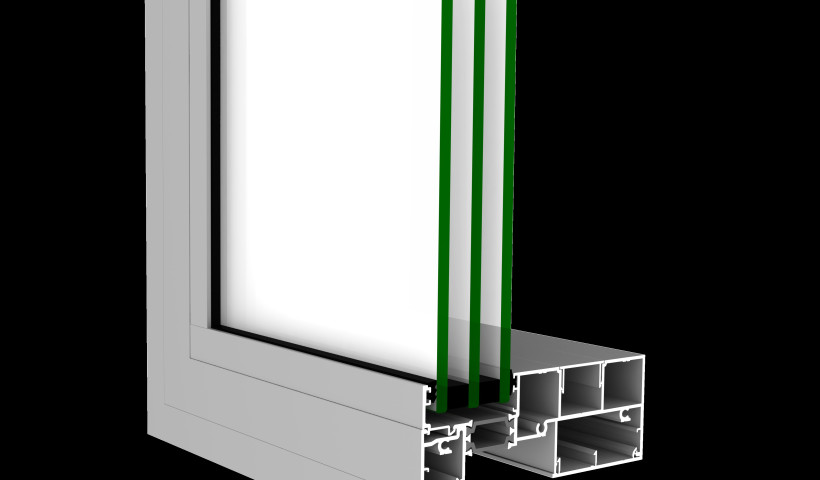

Using the APL 150mm seismic structural glaze system, Origin was required to manufacture windows where no two panels were alike and where there were no right angle joins (apart from the wall corners). Detailed cutting sheets were provided by APL (Architectural Profiles Ltd) for each length of profile and these had to be manufactured by Origin to a tolerance of 1.5mm using long raking saw cuts in complex mitres that were beyond the range of most equipment.

A main split mullion bisected the 16.7-metre-high wall and was fixed back by specially designed brackets to a structural steel beam on the same alignment. The five transoms were all split profiles and each was bracketed to steel support behind. Special hook brackets with jacking bolts were used behind the mullion and these allowed fine adjustment during the installation phase.

"We worked early on and closely with APL, Mainzeal, Chow:Hill, Chesham Glazing and the structural steel fabricators to ensure shop drawing accuracy," said John Luuring, of Origin. "We all then were able to work from the same set of drawings. The accuracy of what was achieved shines out when the final result is viewed. Coordination was the key."

Each window unit was a unique piece of a puzzle, said John, and the puzzle pieces only came together on site. "There was no margin for error, no second chances."

Structural glazing was undertaken at Cheshams where the window panels were laid out and measured. APL supplied the company with the angles, lengths and diagonal checks for the glass. These had to be checked against the manufactured window panels and then bracing applied with straps (in some cases) to achieve the correct diagonals. The glass was then laid and cut.

The 150mm seismic system is designed to allow 16mm of seismic racking.

The bracket placement on the back of the main bisecting mullion was calculated to achieve optimum deflection resistance.

Glazing in 12mm obscure was used and the window powder coat colour was Matt Black.

New Products

New Products

Popular Products from FIRST Windows & Doors

Popular Products from FIRST Windows & Doors

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts