NEW

NEW

In the creation of the Marley Curve diverter, the Marley team connected with over 500 New Zealand households to understand their awareness of downpipe filtration, identify what existing products were being used, and capture their pain-points with existing practices. Marley discovered people were seeking smart and simple solutions — something which really resonates with Marley's values.

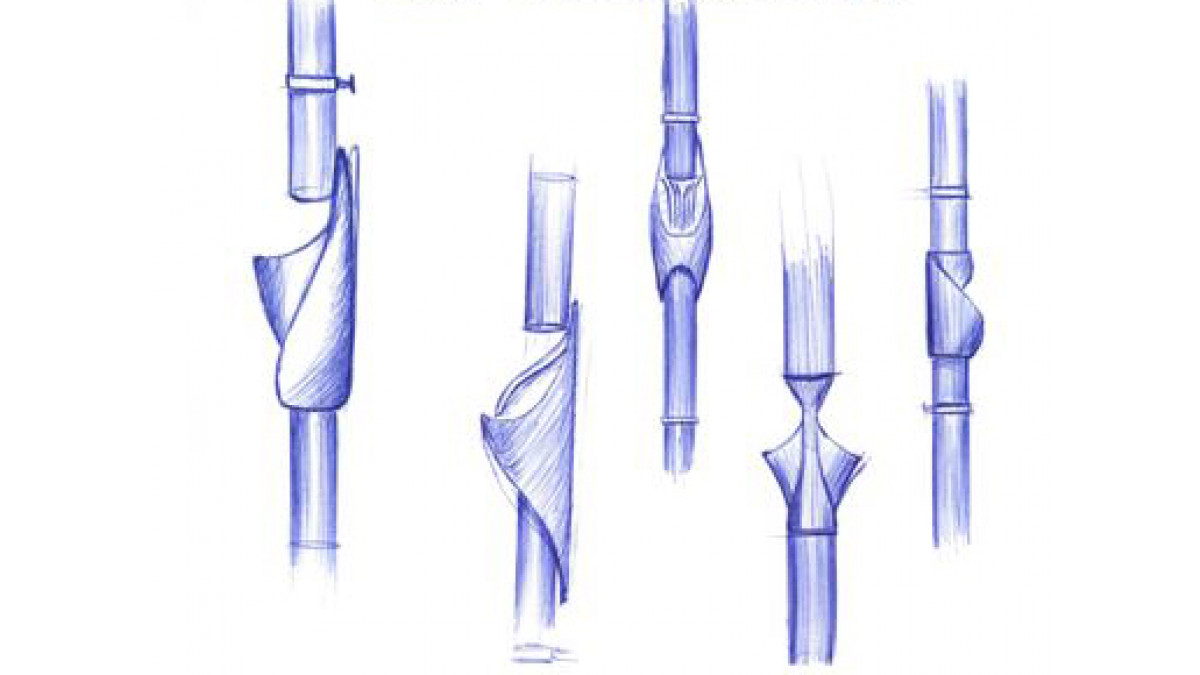

The design process began with creative concept generation and looking outside the industry, and to nature, for inspiration in solving the problem of keeping debris out and drawing water in. The winning concepts were selected for their ability to deliver upon the key product requirements:

- High level of performance (minimal water loss and effective debris diversion)

- In-situ aesthetics

- Low maintenance

- Ease of installation for DIY and trade installers

The final product achieves the perfect synergy of these fundamental design drivers.

3D product design was created using SolidWorks software. Incorporating fluid flow analysis was useful in aiding detailed design of the innovative screen, however, the creation of functional 3D printed prototypes was imperative for extensive in-house testing. These robust prototypes, constructed in nylon from selective laser sintering (SLS) processes were also used for customer and end user appraisal.

Functional prototypes were installed and monitored on homes around Auckland and the Bay of Plenty, with installation conducted by tradesmen and homeowners, with little input from Marley. The first test unit was installed on a house in July providing real test conditions during the wettest months of the year. The Marley team were really impressed with the results, as were homeowners on the trial.

Detailed design of the innovative polypropylene screen was very challenging. Dozens of iterative design improvements were made and prototype testing conducted, chasing the high level of performance required. This was a very difficult part to injection mould, and Marley's injection moulding team were pushed to their limits.

The end-result is an attractive and highly effective leaf diverter. Not only does Curve look great on a house, but with a clean screen it also retains over 99% of the water passing down the downpipe — reducing annoying splash-off and maximising water capture for those on tank supply.

New Products

New Products

Popular Products from Marley

Popular Products from Marley

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts