The standard AS/NZS 4859.1.2018 defines the general criteria and technical provisions of thermal insulation materials for buildings in New Zealand and Australia. The latest update to New Zealand Building Code (NZBC) clause H1 Energy Efficiency stipulates the use of this standard to verify the thermal resistance (material R-value) of insulation materials.

The updated AS/NZS 4859.1:2018 standard will see changes introduced to the way insulation products (bulk, reflective foil and rigid foam) are tested, as well as how thermal performance (material R-value) is calculated and declared. The biggest changes within the amended standard AS/NZS 4859.1:2018 are to do with thermal testing and formal declarations of performance labelling.

Compared to the previous suspended standard (AS/NZS 4859.1:2002), AS/NZS 4859.1:2018 contains new thermal testing requirements that are more stringent. This means the declared material R-values will decrease across the entire range of insulation products.

Specifiers and builders need to be vigilant to ensure the products they’re specifying and buying meet the amended standard (AS/NZS 4859.1:2018). Here’s why:

- If the manufacturers and suppliers are not complying with the new standard, the advertised thermal values for their products may not be accurate, i.e. the stated values will be higher than they actually are.

- Specifying these non-compliant products will affect the thermal performance of the finished building. As a result, the building might not comply with the minimal required thermal performance under the NZBC H1 Energy Efficiency clause.

How to ensure you only specify insulation products that comply with new H1 Energy Efficiency standards

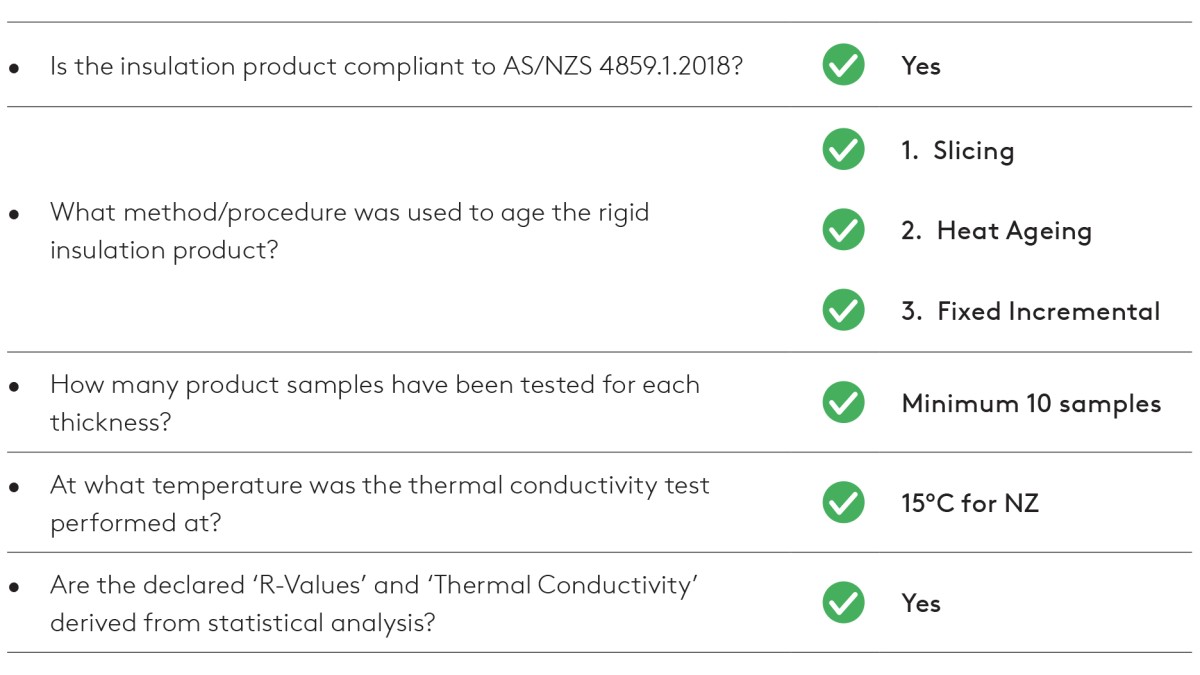

When verifying performance for rigid insulation (Phenolic PF, Polyisocyanurate PIR, Polyurethane PUR and Extruded Polystyrene XPS), it’s important to ask the product manufacturer/supplier the right questions. By asking the questions outlined below, you’re ensuring the information provided is accurate and compliant.

If the product manufacturer/supplier answers any of these questions incorrectly, or quotes a different or equivalent compliance standard, it’s likely their product does not comply with AS/NZS 4859.1.2018.

For example, one of the mandatory requirements detailed in AS/NZS 4859.1.2018 is the use of aged rigid insulation product samples in the thermal performance test. The mean test results are required to be statistically adjusted, so that the thermal conductivity and R-values will represent the thermal performance of the product after 25 years of ageing under normal in-service conditions.

Important questions to ask your insulation manufacturer/supplier (and the answers needed for a compliance):

- Is the insulation product compliant to AS/NZS 4859.1.2018? (yes)

- What method/procedure was used to age the rigid insulation product? (slicing, heat ageing or fixed incremental)

- How many product samples have been tested for each thickness? (minimum 10 samples)

- At what temperature was the thermal conductivity test performed at? (15°C for NZ)

- Are the declared R-Values and Thermal Conductivity derived from statistical analysis (Yes)

How to check insulation product labelling

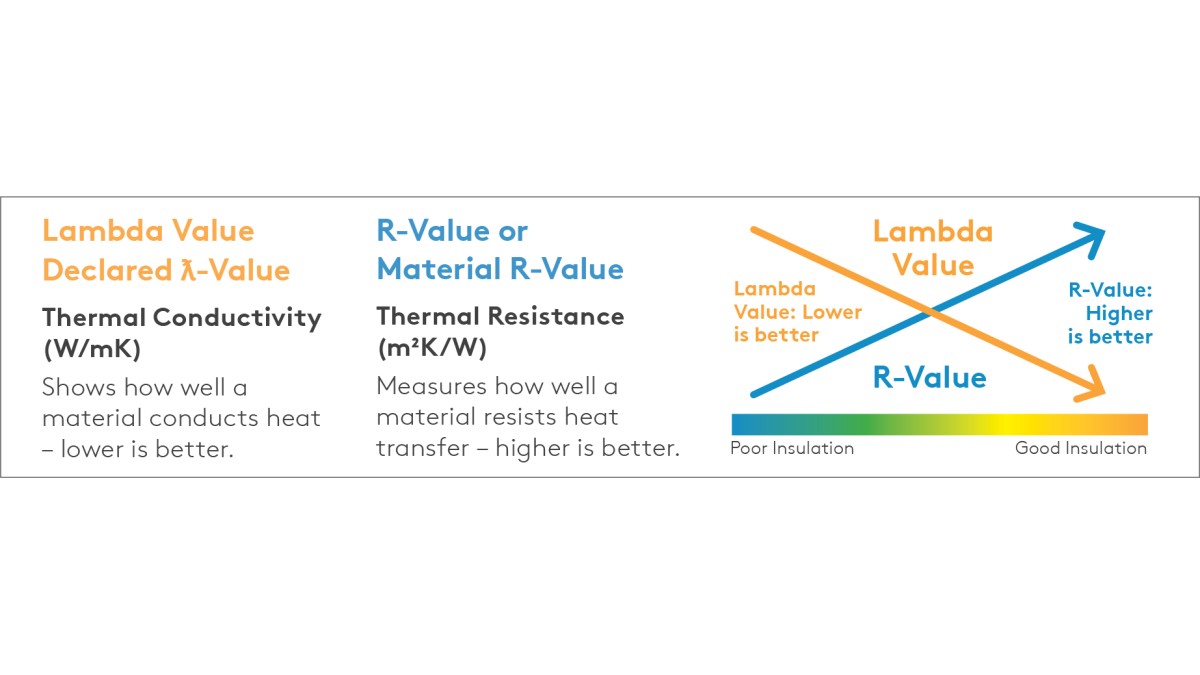

As part of the AS/NZS 4859.1.2018 standard’s requirement, the insulation product’s label needs to include the following information:

- Statement of conformance to AS/NZS 4859.1.2018

- Material thermal performance ‘R-Value’ or ‘Declared λ-Value’ (thermal conductivity) are statistically derived using the R50/90 or λ50/90 method, respectively.

- The relevant temperature for the declared thermal values (15°C for NZ)

It should be noted that ‘Construction R-value’ is no longer acceptable for product labelling.

Want to talk to an expert?

If you’d like help with understanding the new standards for insulation in New Zealand and the differences between material R-value and construction R-value, please call us on 0800 806 595 or email [email protected]

New Products

New Products

Popular Products from Kingspan Thermakraft

Popular Products from Kingspan Thermakraft

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts