These K-Lockers were made off-site at KerMac’s manufacturing premises in Mt Wellington and transported to site where a team installed them in place after the main works had been carried out.

KerMac Lockers are made from robust 6mm/13mm compact laminates, making them a strong and robust product for long term performance.

The great benefit in using K-Lockers is that they perform well in all environments including wet areas such as gyms and pool areas — there is no problem with rusting. The product can take a lot of punishment without showing the after-effects such as damaged doors.

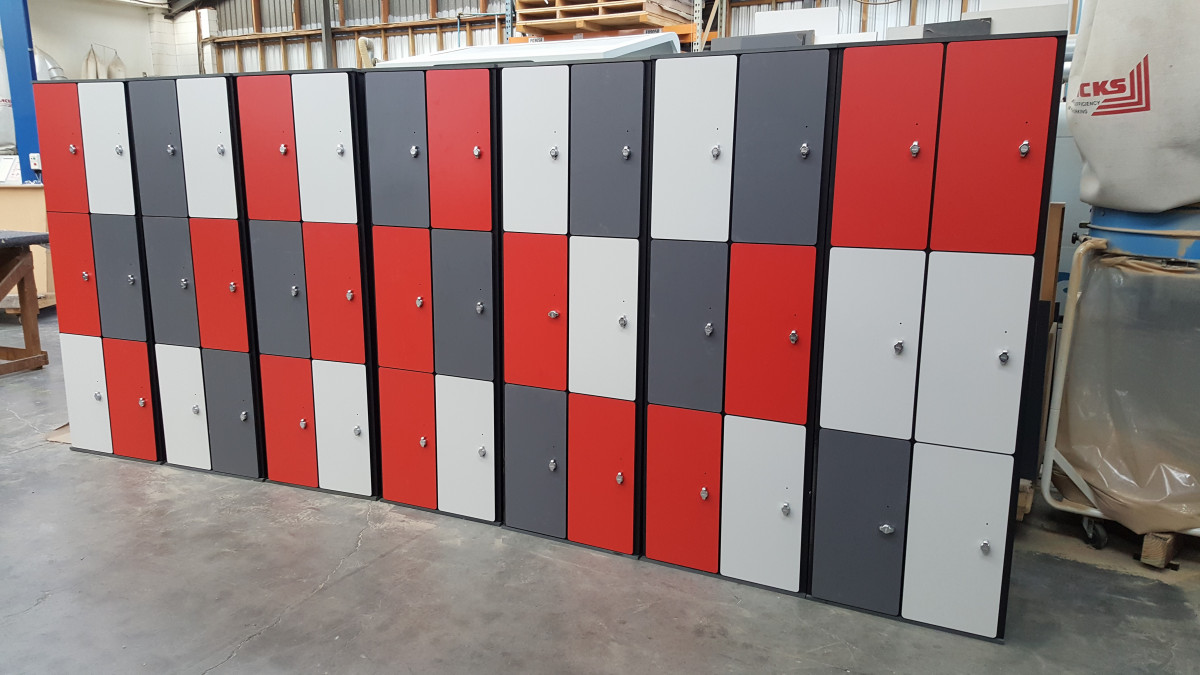

Different finishes and colours can be used to create the right look for the specific area they will be installed into. K-Lockers always look fresh and clean and can be wiped down easily to maintain that new look. Another bonus in using compact laminate is that it has anti-bacterial properties — a great feature in these times when cleanliness is a must.

KerMac K-Lockers are made with aluminium structural frames, compact laminate walls and doors, stainless steel hinges and fasteners.

There is a standard specification for the set-out of the lockers but they can vary in height and width depending on the client’s needs and can be altered to suit a bespoke requirement. The formation of each tower of lockers can be configured into one, two or three lockers and, also a two-locker ‘Z’ formation to allow hanging space for clothing or storage of larger sports equipment for example.

Locking systems on the lockers can vary according to the requirements of the client. Locking devices offered for lockers are padlock system, key system and keyless pad system.

New Products

New Products

Popular Products from KerMac Industries

Popular Products from KerMac Industries

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts