How does Juralco go about ensuring their product designs are compliant with NZ building regulations?

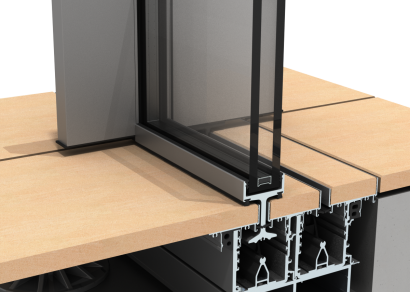

First and foremost, in the design of any Juralco product is the absolute requirement to meet relevant building regulations. Juralco balustrades are SED (Specifically Engineered Design) systems which go through a rigorous design, sample manufacturing and testing process to ensure they comply with AS/NZS1170.

All testing is overseen by an independent engineer, who ensures the product meets the requirements of ULS (Usability Limit State). Once the engineer is satisfied that the product meets the relevant building code requirements and the corresponding product documentation conforms, the product is signed off and a producer statement is generated.

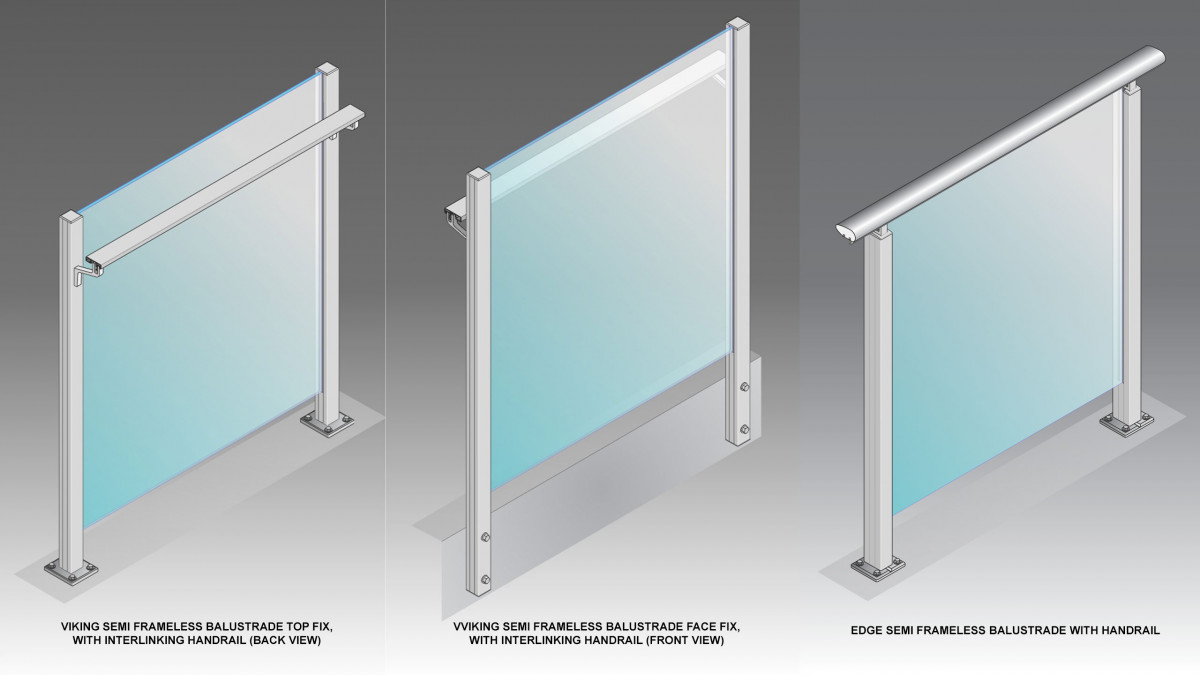

Keeping up with the necessary requirements has been especially challenging in 2016, with changes to NZS 4223.3.2016 affecting the structural design requirements for frameless glass balustrades. On June 1, new legislation requiring the installation of interlinking rails or handrails became compulsory for semi-frameless and frameless toughened glass balustrades. The design, manufacture and testing of suitable rails became the focus for the Juralco balustrade team, particularly as the lead time for the introduction of the legislation was a short six week period. The full range of Juralco balustrade suites was compliant by the deadline, with specially designed low profile interlinking rails and gaskets introduced to the range.

Enhancements of the interlinking rail range continue, along with the research and development of alternate infill options, such a laminated glass for some systems.

For more information, please email [email protected].

Product News

Product News

Popular Products from Juralco Aluminium

Popular Products from Juralco Aluminium

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts