Located in one of Auckland’s leading retail districts, the $790M Westfield redevelopment in Newmarket is a world-class retail and lifestyle destination. The project is the largest undertaken by Scentre Group in Australasia, which operates under the Westfield brand in New Zealand and Australia. It incorporates multiple sites over 4.5 hectares and will be home to more than 230 new speciality stores and a rooftop lifestyle, dining, and entertainment precinct.

The buildings include a concrete floor area of 186,766m², which is about 13 times the area of Eden Park. To construct the buildings, the equivalent of 33 Olympic-sized swimming pools of soil was moved.

The existing structure at 277 Broadway was mostly retained and is linked to the neighbouring 309 Broadway site via an air-bridge over Mortimer Pass. A selection of James Hardie products were specified by architect, Armando Salinas, and Scentre Group’s creative team for their density, durability, non-combustibility and design flexibility.

The building design is sympathetic of its prominent location within the broader Newmarket context, located right next to the motorway. To provide interest and break up the facade, the design team employed different materials such as James Hardie fibre cement, glass, precast, perforated metal, and a ‘green wall’. Titan Facade Panel is a strong architectural feature in the building facade and is a cladding system with a contemporary geometric, expressed-joint industrial look.

The big, bold, geometric panels have been painted in charcoal grey. The panels provide a smooth surface that gives a continuous uniform finish providing a fashionable look, perfect in trendy Newmarket. In addition, Villaboard Lining was applied to entry soffits of the centre, which are designed to be far more open than the now-demolished hub. This cladding combines with a green wall facade of 2,700m² or just over the size of five America’s Cup yacht sails.

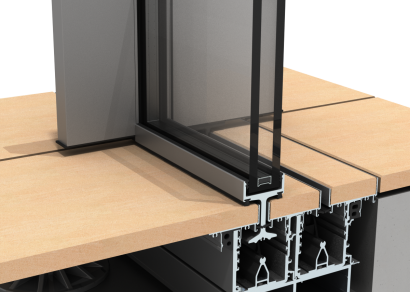

Also ideal in this heavy commercial space is HardiePanel Compressed Sheet, which has been used as a structural floor. It’s a durable, moisture-resistant alternative to particleboard, engineered timber, and plywood substrates, and a lightweight alternative to concrete.

Constructing in the busy retail centre of Newmarket created numerous challenges for construction, with 7,100 tonnes of structural steel used in the buildings — about 12 times the amount used in the Sky Tower. Thanks to the advanced fibre cement composite structure of James Hardie products, they are lightweight and easy to install in constrained sites like Newmarket. The products were erected using a boom lift and fixed to CLD Structural Cavity Battens and RAB Board as a fire rated wall and structural steel components.

This solution enabled compliance with stringent Council requirements relating to fire performance. Where the structural design required stronger, stiffer shear walls, RAB Board 9mm was specified as a rigid air barrier over the 6mm fibre cement sheets, due to its density. RAB Board also allows early close-in which enabled the cladding work to start, meeting the stringent timelines for the project.

The 9mm sheets also provide excellent acoustic performance to combat external noise from the busy local roads and nearby motorway. RAB Board is suitable to withstand high wind pressures and creates a wind barrier which equalises pressure within the cavity to external pressures. Compared to flexible underlays, which can deteriorate from positive/negative pumping actions created by gusting winds within the cavity and on building facade, RAB Board provides greater long-term durability.

Product News

Product News

Popular Products from James Hardie

Popular Products from James Hardie

Posts by Singh Kamboj

Posts by Singh Kamboj Most Popular

Most Popular