NEW

NEW

The Mary Potter Apartments (Te Ara o Puanga) is the brainchild of benefactor Mike O’Sullivan who wanted to set the charity up with an enduring form of financial security to offset its reliance on public donations. Designed by Archaus architect Huw Parslow, the 41-apartment development is tucked behind the existing Mary Potter Newtown facility on a small, steep, brown field site and is predominantly constructed of prefabricated engineered timber walls and mass timber floor panels, all manufactured off-site and craned into place.

“A key driver for the Hospice was a respectful development that would not cause undue stress for the patients in their care, the staff they employ, or the wider community,” says Huw. “The drive to combat noise on-site and create a more environmentally responsible development led the team to use timber as the primary building material and inspired the innovative use of off-site manufactory.”

The project is the only engineered timber framed development of its scale and type in Wellington and it incorporates a host of unique features, including:

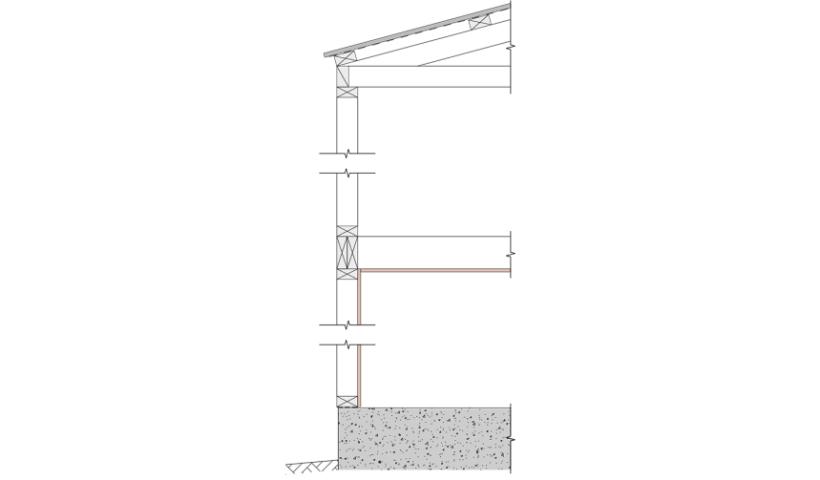

- Glulam timber floors (instead of the traditional reinforced concrete with a floating batten and cradle flooring system)

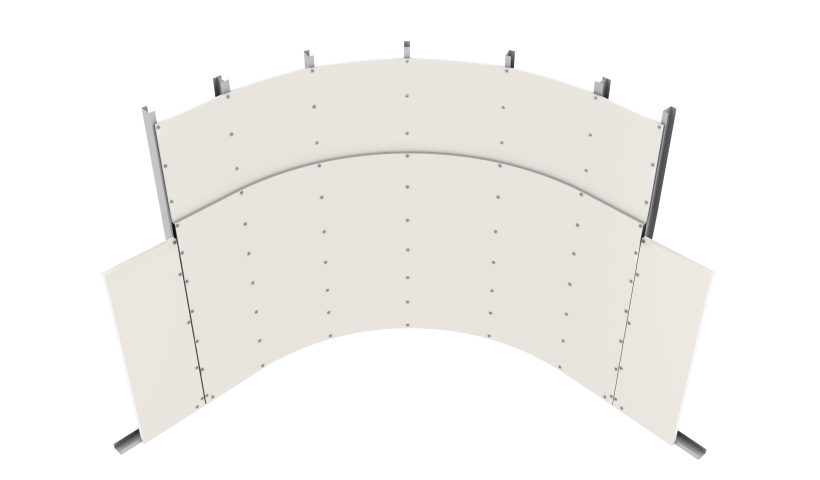

- Inter-tenancy walls made of engineered double-framed Laminated Veneer Lumber (LVL) timber studs with structural plywood bracing and GIB plasterboard linings (for sound and fire ratings)

- External walls made of LVL timber studs, plywood bracing with weathertightness provided by self-adhesive building wrap over the GIB Weatherline external Rigid Air Barrier system.

- The combination of the GIB systems and timber construction provides exceptional acoustic ratings for both Impact Sound Insulation Class (IIC 60) and Airborne Sound Transmission Class (STC 65) the building is seismically restrained with steel vertical tie rod bracing elements.

Four years in the planning stages, the project saw many different design iterations before the final building was agreed upon. Following a hearing, it was granted a Limited Notified Resource Consent under the Housing Accords and Special Housing Areas Act 2013 (HASHAA). The increase in densification and additional height provided by the HASHAA legislation, though challenging, resulted in the existing early 1900s-character properties on Mein Street being retained and renovated, safeguarding the character of the broader Newtown area. Construction kicked off in late 2018.

“The building is a split-level series of interconnected volumes that respond to the steep contours of the site, and the local Newtown environment. The design incorporates variation in cladding materials to break down the building mass into a responsive and sympathetic residential scale. Providing much needed housing in the Newtown area, the apartments are close to the hospital and ideally suited for worker accommodation.

GIB Weatherline played a starring role in construction. When the alternative fire rated boundary wall system failed to provide adequate protection to the steelwork in the wall system depth, the project team opted to use the GIB Weatherline system.

“GIB Weatherline was incorporated as the Rigid Air Barrier for the entire wall envelope of the building, which streamlined the wall types and allowed for the multiple cladding types to align at the substrate without deviation or additional complexity in the façade.”

The project was the first commercial scale residential project to specify GIB Weatherline, and the first one in Wellington to employ the product in off-site manufacture.

“Off-site manufacture meant greatly reduced on-site noise, with the plywood bracing, GIB Weatherline, building wrap and even the windows being installed in the wall panels prior to delivery.”

It also quickened the build and lessened the impact of the development on-site.

Huw says that environmental responsibility was another key component of the brief and played a big part in material selection. Not only is GIB plasterboard Kiwi-made, environmentally certified, non-toxic and compostable, but timber is a renewable raw material grown here in New Zealand, thereby limiting the emissions from transportation.

“The use of timber in construction is a key way for the building industry to respond to the drive for climate change, by sequestering carbon from the environment. Carbon in the form of C02 is captured and stored as trees grow, offsetting the emissions produced through the production of materials such as steel and concrete.”

The unique Te Ara o Puanga development has been extremely well received and is a project that all those involved are deservedly proud of.

Adds Huw, “Te Ara o Puanga is a sensitive and successful development providing much needed accommodation on a disused site in a socially and environmentally responsive fashion, for a worthy client.”

Design and Construction Team:

- Designed by Huw Parslow and the team of Archaus Limited (Architects)

- Engineered by Daniel Moroder and the team of PTL Engineers

- Fabricated at the Concision Factory in Christchurch

- Constructed by McKee Fehl Construction under the watchful eye of Ilan Fisher the site manager.

View further information on www.gib.co.nz/weatherline or call the GIB Helpline on 0800 100 442.

New Products

New Products

Popular Products from GIB

Popular Products from GIB

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts