The 414m-long building, which houses the new AGP glass plant and diverse APL manufacturing operations, is in the final stages of landscaping and is the fifth and most recent 5-Greenstar industrial design structure in the country — and also the largest, with a footprint of 49,000 square metres.

At the well-attended Waikato ‘GreenSpeak’ event, APL’s Executive Director, Sustainability, Mikayla Plaw, was presented with the Greenstar Industrial Design rating certificate by Green Building Council Director, Jennifer Whittle. APL is on the road to receiving their Greenstar Industrial built rating once the building has been completed.

Mikayla said that APL’s current buildings at Te Rapa, in Hamilton, had all been designed to high architectural and environmental standards for their time but the company saw the rural site at Hautapu, as the chance to consolidate the business units onto one site, improve efficiency and move to a new level of sustainability, design merit and building user safety and comfort.

Nick Moyes, Principal Architect at Jasmax, who headed the design team, said that any building with sustainability at its heart started with collaboration. “Our vision for the manufacturing plant was developed jointly with an integrated design approach,” said Nick, “and most key green goals and initiatives were conceived together.”

He said that Foster Construction, the main contractor, played an integral part in bringing the most efficient and effective methods to the site, both for construction and environmental management. Foster holds Toitū Enviromark Diamond Certification, exceeding the internationally recognised ISO 14001 standard, but still had to work hard to meet the demanding Greenstar criteria in selection of sustainable materials, procurement, managing, and monitoring products brought to site and recycling construction and demolition waste.

In the case of the latter, Foster worked closely with APL to achieve an enlarged customer base for waste materials, including packaging. Over 513,000kg of material was recycled, with as many as 10 separate bins on site during the construction phase as well as palletised material and bagged product for returning to manufacturers. This waste minimisation achieved the target of 90% recycle but perseverance was required in the sometimes challenging task of identifying secondary users and outlets, said Mikayla. “It wasn’t always a case of one man’s trash is another man’s treasure.”

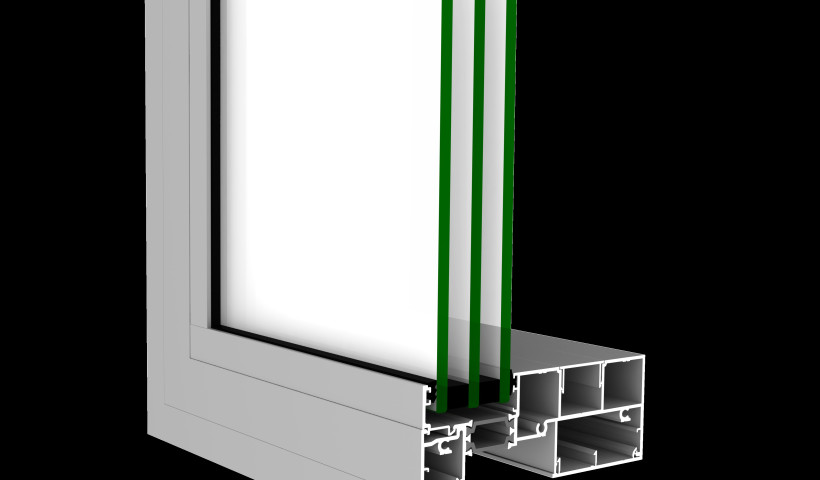

Nick Moyes said that one of the most exciting features of the project came from ensuring that occupant experience was central in design decisions. “For example, daylight and exterior views were a massive consideration and led to the inclusion of five huge skylights (roof windows) that minimise the use of lighting, the second highest energy use after the plant, and allows most occupants to connect to the outside. This connection is something that is so often missing from manufacturing facilities.”

The roof windows (supplied and installed by Vantage window manufacturer, Wight Aluminium) combined with highly efficient lighting systems including dimming controls and daylight sensors, result in a reduction of over 500,000kWh of lighting energy annually.

“We hope the hard work, planning and careful waste diversion programme that went into the design and construction phase of the new building can inspire others who are developing large-scale industrial plants to aim for a Green Star standard,” said Mikayla.

Product News

Product News

Popular Products from FIRST Windows & Doors

Popular Products from FIRST Windows & Doors

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts