An exciting new roofing process was recently trialled and successfully conducted on a large Auckland based warehouse project by Dimond Roofing in partnership with Kiwi Roofing NZ Ltd.

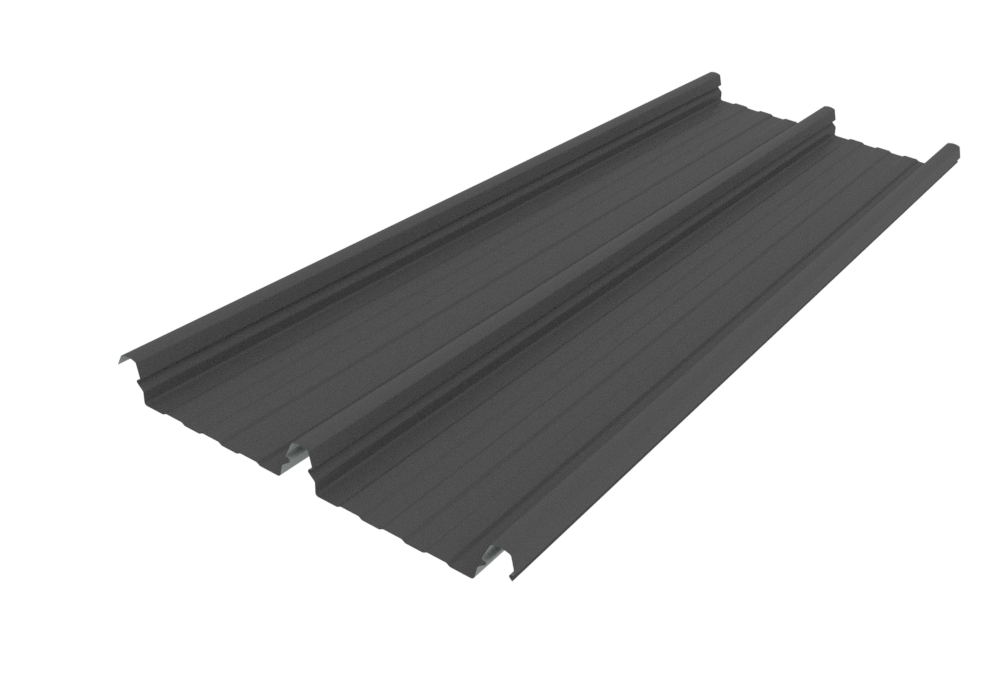

Dimond Roofing currently has mobile capacity in place, which enables them to roll profiles directly onsite, for example, it was recently used for a major project, roll forming DD630 in Napier. The roll-former is containerised, which enables the machine to be transported and set-up and operated where required.

As an extension to this current mobile capability, the new Roll to Roof process sees the mobile equipment craned to the building’s roof level to roll form direct to the building. rather than the roof being roll formed at ground level then craned onto the roof for installation. This has multiple advantages, including removing the requirement for onsite material storage and reduced site space required for processing. The project is significant as it is the first time that this process has been used in New Zealand.

For Roll to Roof, two containers are used, the smaller one to hold the de-coiler, and a larger one to hold the roll forming machine. These containers are craned into place and are secured to anchor points during operation, with the containers being movable to different sections of roof. The containers are also brought back to ground level for a coil change.

Paramount to the process is Health and Safety, given the roll forming is being conducted at height. Focuses have included the health and safety induction process and daily toolbox meetings, crane exclusion zones, PPE requirements and wind controls.

Dimond Roofing was very proud of the first project which went very successfully, and was truly a team effort with the customer, with demonstrated benefits particularly through:

- Cost savings — including reducing the need for on-ground support staff which is generally required during on-site roll forming jobs

- Time savings — by rolling directly to the roof this produced significant time benefits, for example, ad-hoc estimates have concluded significant time savings on this job

New Products

New Products

Popular Products from Dimond Roofing

Popular Products from Dimond Roofing

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts