In our previous articles we advocated for a more holistic approach to fire safety, analysing the characteristics of the substrate and understanding the complexity of the interplay of the various components of mass timber buildings.

We offered a new perspective on how encapsulating engineered wood product (EWP) with intumescent coatings during the very early stages of the build provides fire safety not only during construction but how it later translates into contributing to a fire-resistance rating, enhancing the inherent characteristics of mass timber structures.

Today we want to showcase how encapsulating EWPs with an intumescent coating is providing a passive fire solution that is integrating a systems perspective and therefore able to be truly compliant.

Regulations and the concept of compliance

Traditionally, regulations like the NZBC are based on a highly reductionist view when it comes to compliance. They stipulate that analysing the parts of a system and then putting them back together will enable an appropriate view of the whole.

Unfortunately, focussing on the performance of the parts in order to appreciate the whole — with the aim of optimising the parts in order to optimise the whole – will result in an undesired change to the overall system.

But why is that? Let’s look at an example.

Say the objective is to create a safe mass timber building. In support of this goal, the structural engineer focusses on the building’s structural integrity and opts for increasing the size of the columns used, optimising his sub-system. In the event of a fire, this change would lead to adding significantly to the fuel load, which would extend the burn-out period and increase the fire intensity. The overall result would no longer be a safe building, but one that is more likely to be completely destroyed.

We all have seen the tragic failure of this reductionist view pan out in real life — the ACP panels at Grenfell Towers.

As a consequence of the above people tend to call for an increase in government regulation and stricter rules. This however means doing more of the same and is not addressing the underlying problem — the misconception that everything is connected in a linear fashion.

Thinking in systems: The whole is more than the sum of its parts

Through the lens of systems thinking we are able to better understand that stakeholder goals and technical solutions within a construction project are connected in a circular fashion and that they can be best understood in the context of their relationships with each other. The benefit of this approach is that it is inherently trans-disciplinary and aiming at finding long-term solutions.

Understanding the linkages and interactions among the elements and how balancing and reinforcing processes cause specific system behaviour is especially helpful in projects in which cause and effect are not closely related in space or time.

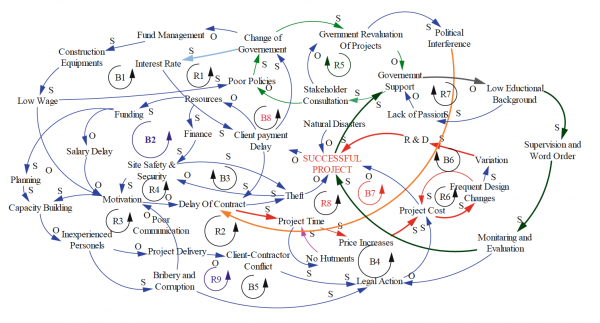

Construction projects are complex systems which have a multitude of relationships and can be best illustrated by the myriad of interactions between the elements.

Figure 1: Mapping out the interconnectedness in a construction project (Source: A systems Thinking Approach to Construction Project Management, 2020)

Zooming in: Buildings are complex systems in themselves

The “building as a system” approach, already used in Canada, focusses on how all the components of a building interact — it includes everything from the exterior to the interior and even further afield, like municipal sewer lines and the electrical grid.

The interplay of these elements can affect their individual performance but also the performance of the other elements. This consideration can make the difference between life and death when it comes to fire safety — highly efficient passive fire components don’t necessarily equate to a safe overall building, if their relation to other elements is not considered.

This makes creating an effective and compliant passive fire system a daunting task. So how to reach fire safety compliance in a complex system?

Compliant passive fire safety in mass timber structures: A balancing act with high stakes

New Zealand has yet to create a specific regulatory framework for passive fire safety in mass timber structures. So how can we be compliant without regulatory requirements?

In terms of fire protection, building codes require all buildings to perform to the same level of safety regardless of materials. Consequently, we can use the current objectives and utilise them as a guide to create a compliance framework for passive fire safety in mass timber buildings. Honouring the holistic perspective at the same time, a compliant solution needs to take into account three aspects:

The substrate

Mass timber is a new material with yet limited long-term experience in how it behaves in fire. Being aware that mass timber is an inherently combustible substrate we need to consider the impact this has on the overall system “building” and reflect this in a passive fire solution.

- The construction phase presents a higher fire risk

It is imperative that we consider fire-safety during construction as the “building as a system”, and this might sound trivial, does not start to exist at the point of its completion, but as soon as the construction process is underway. - High fuel load

Using exposed and structural EWP elements, especially in tall mass timber buildings, adds significantly to the embedded fuel load. This alters the fire dynamics by increasing the duration and intensity of the fire. - Addressing stability and burnout

The heat penetration and continued charring during the fire decay phase lead to further irreversible reduction of the load-carrying capacity of the structure. - Self-extinction and delamination are still not fully understood, thus not controlled

These knowledge gaps limit the ability to design explicitly for burnout stability. Less reliance should be put on inherent fire resistance through charring, while insulative protection should be designed to remain in place until full burnout.

The stakeholders

The various disciplines working in construction align in their overarching goal, but vary in the objectives of their technical solutions. While a designer might focus on aesthetic features and a healthy living space, engineers are focused on structural performance, including in a fire.

A compliant passive fire solution needs to include the expertise and competence of all relevant stakeholders, including builders and applicators, and address any potentially conflicting goals to allow for the best compromise.

The Concept of Fire Resistance

FRR is a risk based approach with the goal to save lives. The three aspects within the FRR concept — structural adequacy, insulation and integrity — add a crucial element to a compliance approach.

Understanding the concept behind FRRs, the implications of the objectives of the three aspects and their interplay e.g., how the concept of encapsulating structural elements addresses the need to control the surface temperature, will allow for an integrated, systemic solution.

Why testing is imperative to proofing compliance

Today’s understanding of the behaviour of mass timber in fire is mainly based on theoretical assumptions. A systemic approach however demands gaining real, opposed to assumed, knowledge. That means, to verify that our passive fire solutions are truly fit for purpose, we need to perform fire tests.

Applying the widely used concept of encapsulation to mass timber and integrating our expertise and the advances of other countries*, we suggest a regime for fire testing “systems”, rather than separate components. This testing regime includes a structural CLT element, a thin-film intumescent coating, topcoat, service penetrations, different kinds of fire stopping as well as linings.

To reflect what happens on site and observe the behaviour of all components in a model situation, we recommend setting up fire tests as a real-life mock-up scenario.

This not only allows us to observe the reaction of the intumescent coating in fire, it also exposes the physical reactions of the substrate (change in surface temperature, the release of combustible gases or charring), and helps us to understand how fire stopping components and service penetrations support or interfere with the others elements.

In recent fire tests, which have been created in line with the described test regime, thin-film intumescent coating solutions have proven to be compliant and deliver on a adequate encapsulation as well as a fire-resistance rating.

Conclusion

To deliver viable passive fire safety for mass timber buildings we require a shift from a linear way of thinking to a systems perspective. We need to study the system and understand the interactions of its elements while focussing on the overall purpose.

Our solutions need to find the right balance in catering to the needs of all stakeholders. They need to perform in fire tests that mimic real life scenarios, which allow us to experience, rather than calculate the impact.

Considering all of the above, a low VOC water-based thin-film intumescent coating can offer these benefits and enables the following gains:

- Alignment with timing of mass timber building schedule

- Increased fire safety during construction (earlier protection)

- Low environmental impact e.g., waste

- A cradle-to-cradle solution (with the coating easily removed)

- Compatibility with other passive fire systems

Intumescent coating solutions can deliver smart, elegant and compliant passive fire protection and contribute to take mass timber construction to the next level.

*Canada is the first to include “Encapsulated Mass Timber Structures” into its Building Code. To address safety during construction a protective encapsulation material, or assembly of materials, providing an encapsulation rating of not less than 25 minutes is required for a certain amount of the mass timber elements.

Most Popular

Most Popular Popular Products

Popular Products