Released in September 2020, the Ministry of Education’s updated ‘Weathertightness Design Requirements for New School Buildings’ document sets the bar high for architects and designers.

Many of the details shown in the document have been purposely set well above current NZBC Acceptable Solutions, in order to dramatically improve the building’s capacity to handle thermal and moisture loads. Like all large property owners, the Ministry is keen to avoid any further disruption and cost related to remediating leaky buildings.

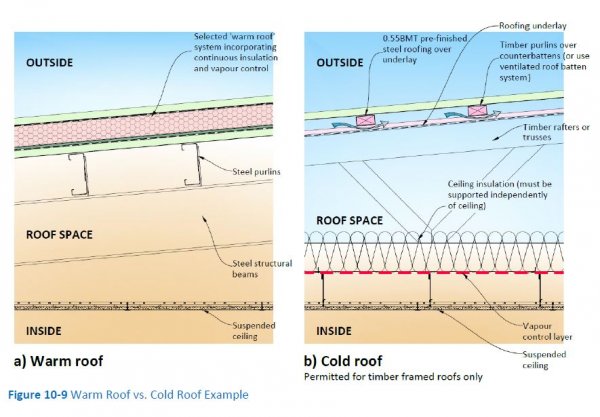

Section 10 of the document deals with Roofs and is where we find some of the biggest changes in design philosophy. ‘Warm Roofs’ (where all the insulation is on the outside of the structure) are now the preferred roof type for new school buildings, especially if the roof structure is steel, to avoid thermal bridging occurring. pro clima SOLITEX roof underlays and tapes are used in many of the Warm Roof systems on the market today, and pro clima NZ Ltd can assist designers with the specification of products in this application and for other parts of the building envelope.

For Timber framed roof structures ‘Cold Roofs‘ (where the insulation is within or below the roof structure) are also permitted if designed and built in accordance with the revised details. Cold Roofs are a good cost-effective option for renovating existing buildings where there are height limitations, or where a Warm Roof system doesn’t quite fit within the project budget.

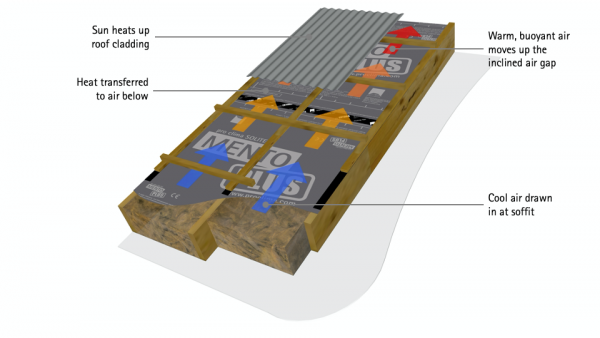

The key differences in the updated schools Cold Roof details vs current NZBC details is the addition of a vapour control layer underneath the ceiling insulation layer, and the incorporation of a vented cavity between the metal roofing and the roof underlay. The vapour control layer minimises the moisture load entering the truss space through air leaks and vapour diffusion. And let’s face it, in a classroom full of sweaty kids, there’s a fair bit of humid air rising! Adding a ventilated cavity between the metal roofing and underlay works just like a vented wall cavity. The movement of air up the cavity provides a cooling effect in the hotter months and allows better management of condensation moisture in the colder months.

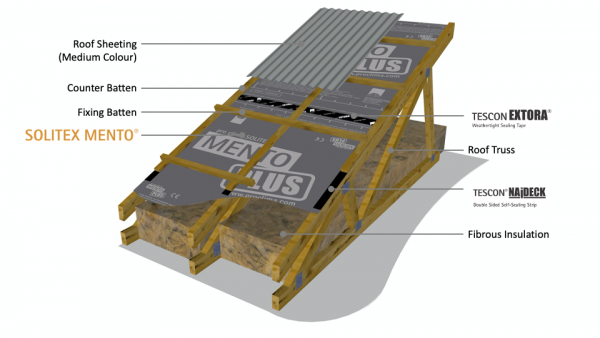

pro clima NZ Ltd have for many years been advocating the use of the Above Sheathing Ventilation method of roof underlay application, and have developed a set of typical Construction Details for both Truss and Skillion roofs, which help make the Cold Roof details shown in the MOE document a reality. These details are based on research and international best practice and give designers all the answers they need on how ventilation, drainage and vermin proofing is achieved at the eaves, ridge, hips and valleys, and the various requirements at different roof pitches.

For the Truss roof option, the truss space itself needs to be ventilated, as well as the cavity above the pro clima SOLITEX roof underlay.

The Skillion roof option is simpler as insulation fills the whole rafter depth (just like on a wall), and ventilation is only needed above the roof underlay. pro clima INTELLO is an intelligent vapour control layer and is used in all the Cold Roof details to minimise the amount of moisture entering the thermal layer, but to also allow drying in the warmer months. Roof colour, orientation, pitch and building location all affect the roof’s ability to handle thermal and moisture loads, so talking to a building envelope specialist or WUFI operator about your project’s specific requirements is recommended.

When combined with good ventilation of the internal space, these higher performance roof systems go a long way towards better protecting the investment we make in our schools, to provide a safe, healthy and more comfortable learning environment for students.

Find out more about pro clima’s Above Sheathing Ventilation system, or call pro clima NZ Ltd on 0800 PRO CLIMA to discuss further with one of the technical sales team.

Most Popular

Most Popular Popular Products

Popular Products