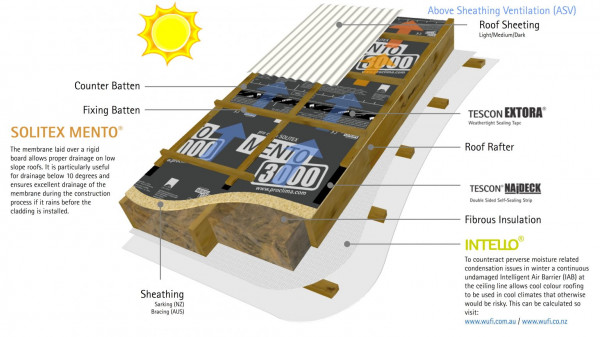

In Part 2 of this series, our brave new roof used Above Sheathing Ventilation (ASV) to battle the dark forces of winter. In the coldest depths of a still night, we showed how ASV can help reduce or even eliminate the evil accumulation of moisture beneath roofing material. But the good work of our roof is not done. Summer brings another set of challenges, but ASV is ready to take on the fierce forces of the Sun!

All the heat reaching the Earth’s surface is from direct radiation which occurs in the line of sight between the Sun (heat source) and your roof (heat receiver).

During a typical sunny day, the surface of a roof will receive at the solar peak approximately 1 kilowatt per square metre (kW/m2) of solar radiation. Depending on the roof colour, between 20% and 95% of this radiation will be absorbed. (Suehrcke, Peterson & Selby, 2008).

Once heat from the Sun has entered our atmosphere it will be absorbed by anything facing the sky, including the cladding materials on our roofs. This can lead to a problem of overheating in our buildings, particularly during the warmer months of our relatively temperate climates. But thanks to the atmospheric gases we are blessed with, we can utilise purpose-built cavities to induce air movement and purge the majority of this heat before it has time to transfer into our buildings.

Reflecting radiative heat vs convective heat removal

Shiny, reflective surfaces (low-emissivity surfaces) are used in space stations to reflect radiant heat from the Sun, thereby reducing excessive absorption. In space there is no atmosphere, therefore no convection (movement of air). In space, all heat transfer is by direct radiative transfer between two objects facing each other.

In 1960s Australia “high-tech”, low emissivity aluminium foils were popularised in roofing construction. Foil based materials have now been applied to construction systems for decades and have become engrained in the psyche of the Australian building industry as the “go-to” solution to improve summer performance. The theory is that adding a highly reflective surface to a roof will help reduce thermal radiation into the building. This is a solution formulated with a myopic view of the climate on our blue planet. It’s an approach that is biased towards summer performance and can therefore exacerbate perverse outcomes during cold, clear winter nights when extra-terrestrial, re-radiation effects take over. When the roof becomes excessively cold in the cooler months of the year, unnecessary moisture issues can occur (ASV – Part 2: The Blue Planet).

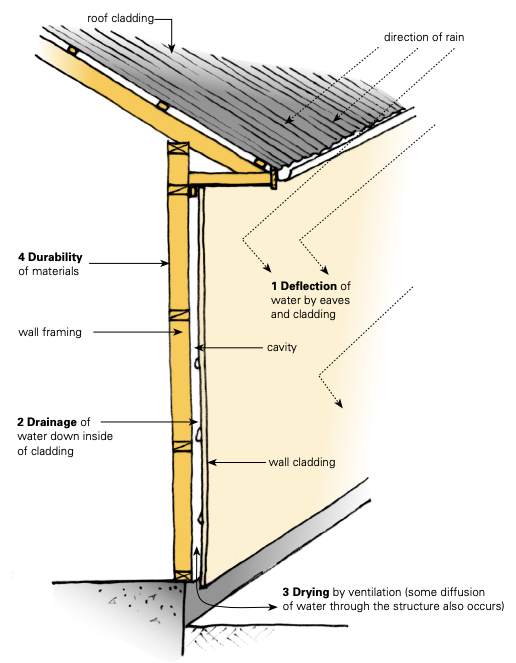

The New Zealand construction industry is more concerned with moisture safe design following widespread and well documented incidents of ‘leaky buildings’ (Dyer, 2019; PWC, 2009). The use of vapour permeable membranes and ventilation combined with the ‘4Ds’ is now standard practice in walls (view image below). However, the summer impact of heat flow downwards in roofs has been paid less attention.

A drained cavity allowing some ventilation between an underlay and cladding has become standard practice for walls in New Zealand following the ‘leaky building’ crisis, but roofs are treated differently. (Image: Department of Building and Housing Te Tari Kaupapa Whare)

Convection removes heat (and moisture)

Above Sheathing Ventilation is the superhero. It allows for the removal of heat via convective airflow. The key to preventing heat flow down into the roof assembly is to utilise controlled, purpose-built convection pathways behind the cladding. We call this Above Sheathing (Membrane) Ventilation (ASV). In Part 2 we explained how ASV helps to remove moisture in winter. We will now look at ASV’s other secret power, removing heat in summer.

Heat islands

Altruistic design choices can lead to an overall reduction in the peak summer temperatures experienced in urban areas. Choosing heat reflective colours (light colours) and increasing tree foliage are often cited and proven effective strategies.

We know black is hot and all cricketers know white stays cooler. White roofs increase the albedo. The light colour reflects more of the incoming radiative heat from the sun. Some roof cladding materials can achieve up to 77% solar reflectance. This means only 23% is absorbed by the cladding (Blusecope, 2021). The regulations in Australia allow less insulation for lighter coloured roofs in warmer “summer dominant” climates (NCC Vol 2, 2019).

The magnitude of overheating in Sydney, Australia, has been calculated at close to 9°C. This causes a cooling penalty of up to 16% and an increase in the indoor overheating levels of up to 56%* (Santamouris et al., 2020). To combat this Santamouris et al. suggests: “Reflective surfaces can decrease the peak ambient temperature in Sydney by up to 1.5 °C, […]. Therefore, the deployment of tested and durable reflective materials is of the utmost importance, since weathering, soiling, chemical stress and biological growth can result in considerable optical ageing and an increase in solar absorptance.” An example of this is shown below.

Over time the absorptivity of the roof will increase as the roof ages, surfaces dull and dirt, grime and lichens accumulate. (Image: Jesse Clarke, Pro Clima Australia)

Roof colour — a double-edged sword

Almost all climate zones across Australia and New Zealand have a distinct summer and winter. This may seems obvious, but it does become less apparent in the far north tropical zones. We therefore need solutions that can handle both extremes. Lighter coloured roofs induce cooler temperatures in summer, which is good. However, a lighter coloured roof will also lower the average roof cladding temperature and sub-layer temperatures in winter, which potentially exacerbates moisture related issues. That’s not so good.

The solution is to design and construct effective water, air, vapour and heat control layers. (ASV – Part 2: The Blue Planet.)

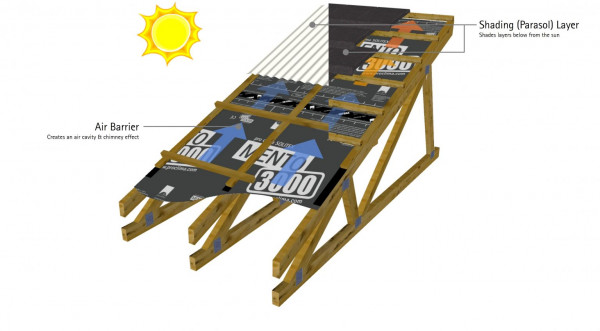

The umbrella academy

A parasol is a lightweight umbrella used to give shade from the sun. In architecture, a parasol roof is a light roof that shades the main structure from the sun. It has been used for decades by architects in hot climates to improve summer comfort by blocking the sun and removing heat by convection from the underside of the parasol. Although these roofs are often complex and generally reserved for architectural homes with larger budgets, the fundamental principles can be employed on a smaller scale utilising convective air currents to remove large amounts of heat and moisture.

If the umbrella is a light, heat-reflective colour, then the parasol works even better to fight the sun. But we need to be conscious of the equal and opposite reaction in winter

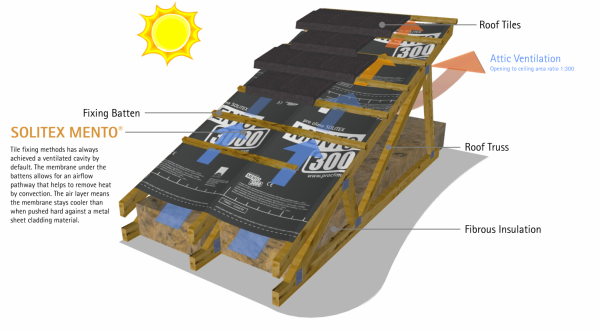

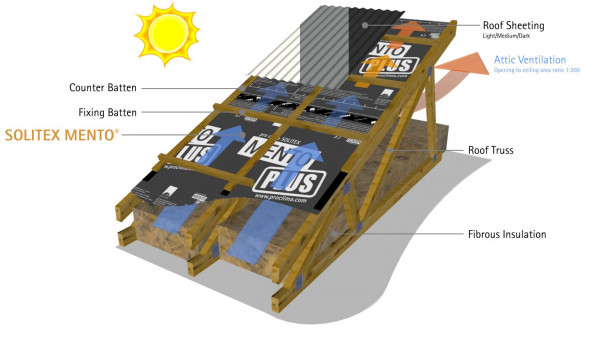

In many countries and for many years, pitched roof constructions with tiles made of clay or concrete used to be built with a ventilation layer underneath the tiles (see image below). In this situation the battens, which are needed to attach the tiles, typically create a thin air layer which can move by heat induced convection (Kölsch, 2019).

Tiled roofs have always allowed for incidental airflow under the battens and tiles, but not necessarily with dedicated inlet and outlet openings.

The air exchange created by the movement of air under the tiles reduces overheating of the attic during summer (Kölsch, 2019).

This same principle of airflow under a tile system or the parasol roof can be intentionally designed into a roof assembly with the inclusion of a dedicated ventilation pathway. A roof with this type of build-up will remove significant amounts of heat regardless of the cladding material or colour.

Purpose-Built airflow pathways allow heat to be removed before it reaches the insulation layers below.

Self-regulation

Evidence suggests that a light colour roof with Above Sheathing (Membrane) Ventilation delivers the best summer performance, but the penalty for a mid-dark colour may not be as high as you would think.

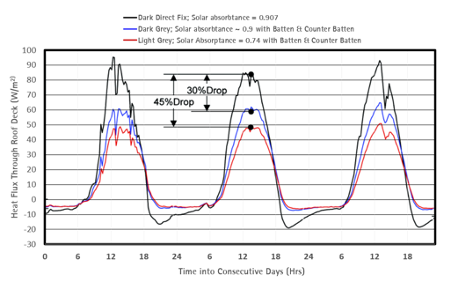

Self-Regulation effect of different absorptance roof colours.

2006 research from Oakridge National Laboratories in the US found that “regardless of roof colour the stack effect ensures the system is self-regulating. Darker roofs create a stronger stack effect removing more heat.”

Test roof At Oakridge National Laboratory. (Miller, Wilson & Karagiozis 2006)

The effect of Above Sheathing Ventilation and solar reflectance for two metal roofs compared with a direct-nailed shingle roof. Stone-coated metal installed on batten and counter batten systems. These roofs were offset from the roof deck by about ¾in. (0.019 m) using a batten and counter batten system. (Adapted from Miller et al. 2006)

Using this strategy of increased solar reflectance and Above Sheathing (Membrane) Ventilation results in a reduction of heat flow penetrating the attic floor by 70% during daylight hours, compared with the heat flow penetrating the attic floor of a roof with conventional asphalt shingles (Miller et al. 2006).

Given that sheet roofing in Australia and New Zealand is available with just 23% solar absorptance, ASV can be used in conjunction with ventilation strategies to further enhance the cooling effect. When designed and constructed appropriately, a roof can protect against wintertime condensation as well as summertime overheating.

Bigger is better (in summer)

The dedicated pathway beneath the cladding needs to include sufficient height and cross-sectional area for unimpeded airflow. The effective ventilation area is taken as the cross-sectional area created by the vertical counter battens.

When promoting airflow under the roofing systems, this is a case of bigger is better. Larger vertical counter battens allow for higher volumetric airflow with less resistance and thus better heat removal. The bigger it gets the more it becomes like a full parasol roof.

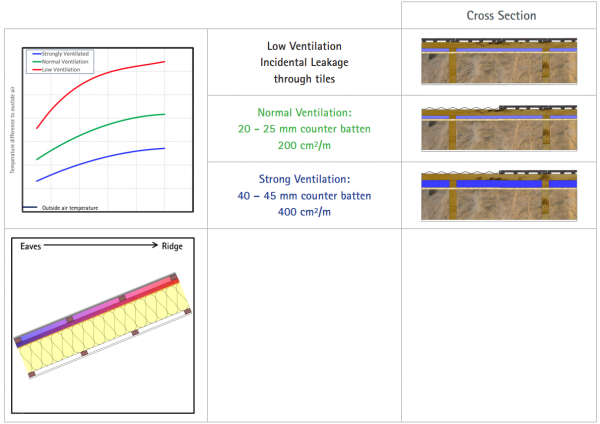

The height of the counter battens can be increased to enhance the airflow and heat removal in summer.

The behaviour is like a heat exchanger. The larger the unrestricted airflow pathway, the cooler the cavity, and the less work the insulation below needs to do. The net result is that the temperature difference curve flattens (Kölsch, 2019).

The effectiveness of the ventilation for removing heat is related to the counter batten height. Low, Normal or Strong Ventilation can be designed. (Adapted from Kölsch, 2019)

Design thresholds for the inlets and outlets are also critical. For best performance in summer, it is always better to seek a strong ventilation strategy. This means utilising taller counter battens and larger inlets and outlets so as to not restrict the airflow. The Central Association of the German Roofing Trade (Zentralverband des Deutschen Dachdeckerhandwerks dachdecker) and DIN 4108-3 standard practice result in opening ratios at the eave and ridge achieve a “low”, “normal” or “strong” ventilation strategy as described in Table 2 (DIN, 2018). These opening area ratios form the basis of design thresholds which have been studied with specific Above Sheathing (Membrane) Ventilation strategies from the Fraunhofer Institute of Building Physics (IBP) for both winter moisture and summer heat removal.

In New Zealand and Australia, corrugated sheet metal is a common roof cladding material of choice. It is worth noting that the corrugations in typical profiles provide an open area of approximately 60 cm²/m.

It is of course important to check local requirements for vermin and bushfire protection. These meshes and screens may have anywhere from 10% to 90% open area ratios and will reduce the resulting inlet/outlet opening area correspondingly.

Inlet, outlet and counter batten arrangements for different ventilation strategies.

The corrugations in sheet metal will achieve ~60 cm²/m of roof ridge. The ridge caping fixed without dressing down into the corrugations can provide sufficient ridge opening area.

Super solutions

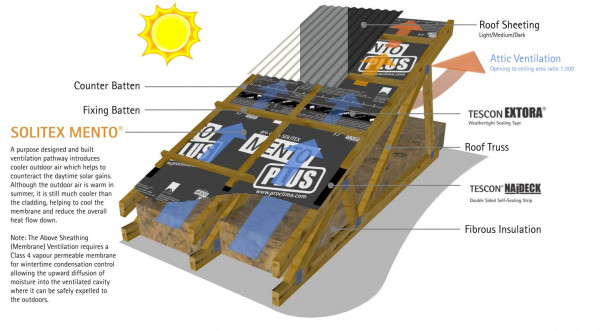

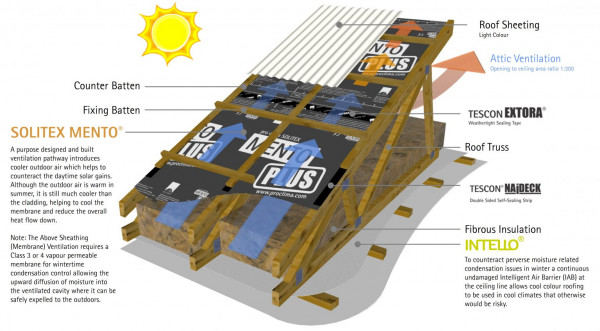

Structured ventilation strategies require specific addition of ventilation behind the cladding and within any large air voids (attic / roof / truss space) above the insulation layer. This formulates the basis of super strategies to remove heat and moisture at the cladding level and from within any uncontrollable large air voids in the roof structure.

Design requirements — structured ASV

It is recommended only “normal” or “strong” ventilation strategies are employed for the cavity between the cladding and the WRB.

The design thresholds are:

- Normal Ventilation is achieved with nominal 20 mm high counter battens. This achieves approximately 200cm² of roof cross sectional open area per lineal metre.

- Strong Ventilation is achieved with nominal 45 mm high counter battens. This achieves approximately 400cm² of roof cross sectional open area per lineal metre.

- The eave free open area should be no less than the roof cross sectional open area, including any adjustments for vermin or bush fire mesh.

- The ratio for the structured ASV ventilation opening sizes should be minimum 1:4, where the ridge vent area is at minimum 1/4 of the calculated eave vent area.

Roof form adjustments

- Where the resulting ridge length is less than the eave length (e.g. hip roof) due to geometry, the eave inlet size should be calculated based on total eave length and the outlet at the ridge distributed evenly along the ridges with a vent opening area of 1/4 of the total eave inlet area. This means ridge vents may need to be enlarged compared to a basic gable or mono-pitch roof.

- On the sections of a roof where there is no ridge parallel to the eave to fit an outlet (e.g. any type of hip roof), then an additional vent would need to be added.

- Where the ridge is venting two ASV roof sections on either side (e.g. standard gable), then the ridge capping vent area needs to allow for the total openable area for both sides.

Remove heat using a designed ventilation cavity under the cladding. Cooler air entering the cavity at low level absorbs heat from the cladding as it rises to the ridge or high point. The ventilation therefore helps to cool the membrane reducing the overall heat flow downward into the living space.

Design requirements — ventilated roof spaces

- Pro Clima recommends that large air voids on the outside of insulation layers (e.g. truss spaces) are ventilated, unless specialist hygrothermal design advice has been sought.

- Recommended total open vent area including eave inlets and ridge outlets should be equal to the 1:300 ratio between the net free opening area of the vents to the area of insulated ceiling.

- Approximately 30% of the total unobstructed vent area required should be located not more than 900mm below the ridge or highest point of the roof space, measured vertically.

- The remaining 70% of required opening area should be provided by the eave vents.

- Dimensioning inlet vents larger than the outlets ensure all makeup air comes from the outside and is not drawn from the inside.

- The outlets for the ridges will be based on the greater of:

- The ridge ventilation requirement for the structured ASV ventilation pathway behind the cladding, or

- The requirement for the ventilation of the attic based on 30% of the 1:300 ceiling ratio ensuring the ridge capping detailing allows for the required open area.

- Eave vents should be evenly distributed around the roof perimeter.

- Outlet vents, such as ridge vents, must only be installed in conjunction with inlet vents.

INTELLO or INTELLO PLUS Intelligent Air Barrier system at the ceiling line coupled with a services cavity allows a continuous an undamaged vapour control layer which limits the upward movement of interior air into the roof space.

Design requirements — mesh

To prevent vermin in cavities it is accepted in New Zealand that 3 – 5 mm mesh is suitable (Department of Building & Housing, 2011).

In Australia, cavity closers must meet AS 3959 requirements for bushfire protection up to BAL 40 (Standards Australia, 2018). This can be achieved by fitting an ember guard made of non-combustible material, or a mesh or perforated sheet with ≤2mm holes made of corrosion-resistant steel or bronze.

Design requirement — cool roofs

The addition of an intelligent air barrier and vapour control layer at the ceiling level, adds further protection by limiting the pathway for warm, humid air to enter the roof assembly in winter.

Cooler coloured roofing systems can be used for enhanced summer performance in mild to cool temperate climates using pro clima INTELLO PLUS to manage winter condensation risk. The roof assembly can be super enhanced by removing the large void altogether, as is the case with a skillion or cathedral roof using the structured ASV design requirements. This provides the most predictable outcome for beating moisture and heat.

Removing the large air void inherent in truss roof design means the thermal and moisture characteristics of these roof systems are highly predictable. As such, with the right professional advice you can rest assured your roof will work as you intended in summer and in winter in any climate zone. Roof slope should be limited to 5 degrees with the SOLITEX MENTO system to facilitate drainage. Ask a professional for verification.

ASV — The year round superhero

Above Sheathing Ventilation (ASV) is a year round roofing superhero. During the coldest depths of winter nights, air movement between roofing cladding and the membrane will help reduce or even eliminate condensation from the underside of roofing material. Any condensation that does form can be freely drained away via the clear pathways created between counter battens.

But ASV’s work isn’t done when winter is over.

Harsh summer conditions expose roofs to severe solar radiation. Left unchecked, this can add significant and uncomfortable heat loads to our buildings. But the air movement induced by ASV can come to our rescue yet again and work to keep our buildings cool, no matter the cladding type or material colour.

So far in this series, we’ve exposed that there’s no secret serum to creating a super roof. There’s just good science. In the final two parts, we’ll look at the all-important details of eaves and ridges to help designers and builders go above and beyond.

Most Popular

Most Popular Popular Products

Popular Products