The origin story

Every superhero needs one. If Above Sheathing Ventilation (ASV) is the superhero of roofs that work, then how and why did ASV come into being?

We have a problem with the way we’ve been doing roofs in New Zealand. In fact, we have multiple problems.

Roofs are there to keep us dry. This seems fairly simple when we just want to shed water away and don’t have to worry about things like condensation. But as well as being protected from the rain, we’d also quite like to be warm, and we’d like for it to not consume too much energy to keep us warm.

To help with this, we’ve added insulation and also sealed up parts of our building envelopes. Now we’re dealing with temperature gradients and vapour pressure, and things are getting interesting.

Most of us are all too familiar with what happens when it’s relatively warm and humid inside, and cold outside. If our building envelopes are not designed and constructed to deal with these differences in indoor and outdoor conditions, we end up with condensation.

Condensation is one symptom of poor building envelope design. In New Zealand, we deal with this symptom by requiring an absorptive material to be placed directly under the roofing iron (similar to AS 4200.2 shown in Figure 1). The theory is that any condensation that forms (usually at night time) will either be absorbed by this roofing underlay or drained away. Then when the roofing material heats up (during the day), the heat will essentially bake the underlay dry again.

Problems start to occur when this cycle is repeated day in, day out. The underlay material is exposed to some extraordinary conditions. Super high temperatures occur in the middle of summer and very cold temperatures (often five to ten degrees below ambient air temperature) are common during winter nights. Just how high is high? Research shows that 90°C (194°F) is not uncommon (Cullen, 1992; Munro 2008; ETAG, 2004; Ali, 2015). For more on this, including some of our own research, stay tuned for upcoming episodes in this ASV technical series.

Add continual wetting and drying to these extreme temperature fluctuations and the conditions created become similar to what laboratories use for accelerated ageing!

Figure 1: AS 4200.2 Figure 3.4.1 is typical of the way we’ve been doing roofs in Australia and New Zealand – with a membrane over purlins and the roofing material installed directly on to the membrane. This arrangement presents some problems.

What sort of materials can withstand this sort of treatment? Unsurprisingly, not many. Most underlays and tapes will look very worse-for-wear after only a few short years of their intended life under these conditions (see Figure 2 and Figure 3).

Figure 2: This is not a leaky roof. The amount of condensation forming on the underside of roofing metal is in excess of what can be absorbed or drained by the underlay and puddles form. The extreme conditions under the metal have also caused wrinkles and sagging, plus the mould is starting to grow.

Figure 3: Temperature fluctuations cause expansion and contraction of underlay materials which can lead to rips and tears, especially in composite underlays where different materials behave differently with varying temperatures. Image courtesy Darren O’Dea.

As well as the stresses and resulting damage to underlays, there are other problems with putting roofing material directly on top of an underlay over battens or rafters:

- Penetrations through the roof cladding create holes in the underlay, thereby creating lots of little pathways for any condensation to leak through into the rest of the building.

- When moisture accumulates in excess of what can be absorbed, the system relies on free drainage. Free drainage relies on a clear path all the way down to the eave and ideally into the roof spouting. But extreme temperature and humidity changes typically cause expansion and contraction of the materials which leads to sagging, and this, in turn, can create ponding (see Figure 2). The problem is particularly apparent in low pitched roofs and where there is no solid substrate (sheathing) supporting the underlay.

- Wrinkles, folds and multiple areas of direct contact severely limit any effective ventilation of what limited gap there is between the roof and underlay. In addition, most roofers go to great lengths to seal up this space as much as possible by folding down corrugation ends and installing tight fitting flashings.

- Extreme temperatures impact the health, comfort and efficiency of the building. As noted above, temperatures under the roof cladding of a typical construction where there is not adequate ventilation can reach up to 90°C (194°F). This heat will transfer into the building either contributing to discomfort or unnecessarily adding to the energy required to keep cool.

- In truss roofs, the top of the insulation is left unprotected. There’s just a big space between the underlay and the insulation. In this setup, air is free to move around and through the top layer of the insulation, thereby reducing its effectiveness.

There is a better way to design and build our roofs and it’s all about putting adequate ventilation in the right place, because:

- Ventilation below roof cladding is better than absorption for managing moisture.

- Ventilation between the roof cladding and the membrane is better than reflectance for managing heat.

With all this in mind, let us introduce you to Above Sheathing Ventilation.

Let’s be flexible

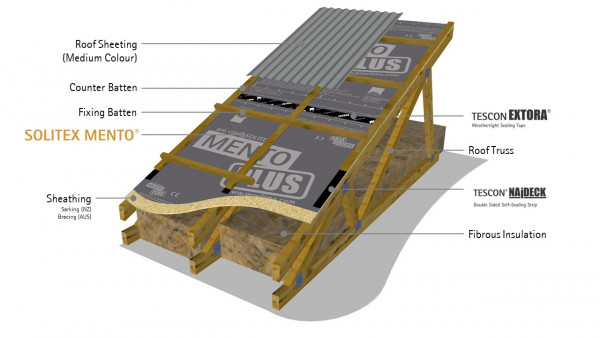

Strictly speaking in this part of the world, it’s ‘Above Membrane Ventilation’. Sheathing is the solid substrate installed on top of structural elements and underneath the cladding (see Figure 4).

Figure 4: Technically, ‘sheathing’ refers to rigid boards placed onto the rafters or top chord of a truss in order to support the membrane under the cladding while providing structural support to the roof. *Specific products may vary.

It’s a term commonly used in the US for the rigid boards that are laid over the rafters of roof trusses. This board has a structural function, but is also there for holding up the water barrier membrane and supporting it against wind loads behind the cladding systems.

If we were describing a wall, then a rigid air barrier would be an example of sheathing.

And as with walls, where not all situations require a rigid air barrier, a flexible barrier without sheathing may be sufficient. This flexible barrier might be a membrane or sarking.

Therefore we could call this method, ‘Above Sarking Ventilation’ but in Australia ‘sarking’ typically means foil. Foils are discouraged because non-permeable membranes (even perforated ones) don’t have a place in modern buildings… but that’s a whole other topic.

So while ‘Above Sheathing Ventilation’ (ASV) may not always be a completely accurate descriptor, at least Australia and New Zealand will have some consistency with the rest of the world. Let’s not get too hung up about the word ‘sheathing’ though. The most important word in ASV is Ventilation.

A ventilated cavity

A result of the $47 billion (Peter Dyer 2019) ‘leaky building’ crisis is that most New Zealanders are familiar with the concept of, and importance of, a ventilated cavity with respect to walls. Why should roofs be any different?

While most would agree that ventilation in the roof is a good idea, there is some confusion about the best place for it.

A common assumption is that ventilation already occurs, either under the peaks of metal corrugations, or in the small (and irregular) spaces between the edge of tiles and any underlying membrane. These air spaces are relatively small and should not be confused with the air layer in ‘ventilated’ roof assemblies. The intent should be to have specifically designed ventilation in a specific location for a specific purpose.

Where the membrane goes

In New Zealand, pitched roofs with clay or concrete tiles have typically been constructed with a membrane directly beneath the tiles and a ventilation layer underneath this membrane. In Australia it is common to have no secondary weatherproofing layer below the roof tiles at all. The theory is that if (or when) the cladding leaks, then large quantities of airflow in the roof will dry out the construction.

When it comes to long run metal roofs, the continuous metal sheeting is often believed to be a perfect water barrier, so “she’ll be right mate!”.

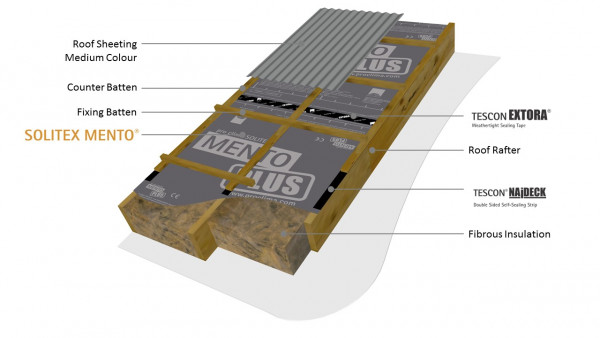

However, membranes or ‘underlays’ play an important role in the building envelope. They’re the real weatherproofing layer because we know that claddings aren’t perfect. All building cladding will eventually leak. The weathertightness membrane should be placed where it provides the best protection for the thermal layer of the building envelope. In a wall or skillion roof, this means directly in contact with the insulation (see Figure 5).

Figure 5: In a skillion roof, the ventilated cavity should be created between the underside of the roof cladding and the roof membrane. The membrane is placed directly on top of and in contact with the insulation. It’s separated from the roof cladding by battens and counter battens. *Specific products may vary.

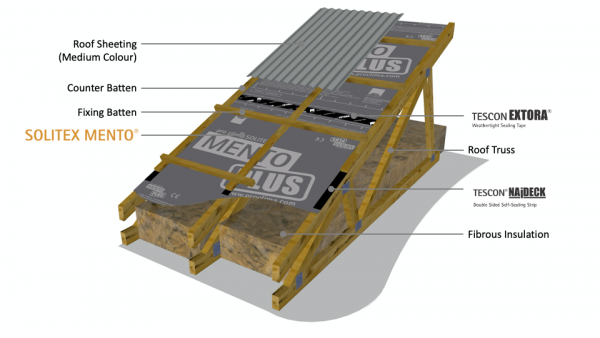

Truss roofs are more common in Australia and New Zealand. In this instance, the same attention should be paid to designing the ventilation space between the roof cladding and the membrane. It’s essentially the same as for a skillion roof but with a gap between the membrane and the insulation (see Figure 6).

Figure 6: The ventilation arrangement for a typical truss roof is the same as for a skillion roof. A ventilated cavity is created between the roof cladding and the membrane by battens and counter battens. The insulation is still protected by the membrane above, but with a void between them. *Specific products may vary.

Above Sheathing Ventilation (ASV)

ASV can be implemented by adding counter battens (running vertically) directly above the weathertightness membrane. Regular battens (running horizontally) are then attached above the counter battens to form the fixing structure for the roof cladding (Figure 7).

Figure 7: Ready for the roofing cladding to be installed, this site shows the arrangement of counter battens (running vertically) and battens (running horizontally) to form a drained and ventilated cavity. *Specific products may vary.

The counter batten construction provides an air space between the exterior face of the roof sheathing and the underside of the roof cladding so that a clear air pathway exists beneath the roof cladding from the soffit to the ridge.

Solar powered ventilation

ASV uses energy from the sun to induce an airflow in the air space between the cladding and the membrane. The sun heats up the roof cladding and this heat is transferred to the air in the cavity below. The warmer, and therefore more buoyant air moves up the inclined air gap creating solar powered ventilation (see Figure 8). Miller, Wilson, and Karagiozis (2006) observed that this type of ventilation helped remove unwanted heat and moisture from the roof deck, thereby improving the roof’s thermal performance as well as its durability.

Figure 8: ASV is solar powered ventilation. Heat from the sun shining on the roof cladding, warms up the air beneath the cladding and induces a flow that moves the air upwards towards the ridge, while drawing in more air at the soffit. *Specific products may vary

Benefits of Above Sheathing Ventilation (ASV)

Various building science studies from around the world have found that no matter what the roof cladding type, there are significant benefits to providing ventilation between the cladding and a secondary weathertightness layer using battens and counter battens.

The three main benefits of ASV are:

- The counter battens enable free drainage of water on the membrane or the underlay boards.

- The air exchange reduces overheating of the attic, regardless of the colour of the roof cladding, thereby reducing the cooling demand of the building while creating more comfort internally.

- Air movement in the layer helps to remove any moisture that might accumulate either via water vapour permeating from the interior of the building, or from dew condensing from ambient air entering the cavity.

Design for effectiveness

Up until now, we’ve been designing and constructing roofs with adaptations to address symptoms. In New Zealand we’ve relied on roofing underlay materials to absorb inevitable moisture on the underside of roofs. In Australia it’s common to simply rely on mass movement of air in the roof to dry out any accumulated moisture. But there’s a better way.

By understanding what’s going on in our roofs, we can design systems that keep our buildings dry, healthy and durable. The science shows that Above Sheathing Ventilation (ASV) makes sense.

In following episodes we’ll go into more detail about how water can get into our roofs and how we can get rid of it, the importance of the sun and how we deal with heat, and we’ll explore the all important details of how to design and construct eaves and ridges for effective ventilation.

Most Popular

Most Popular Popular Products

Popular Products