In last month's blog post, I discussed the types of glass best suited to different structural applications. As I continue this series on structural glass, this month I want to discuss sealant, fixing and hardware.

Considerations for sealant

Glass is a brittle material which makes it sensitive to stress concentrations. Therefore, adhesives are good alternatives to mechanical glass joints since they spread the stresses over the surface of the joint.

There are many types of sealant used in glass. Joint size must be designed for the specified design load.

The sealant bite can be calculated using the equation in NZS4223:1, from the wind load and glass span. The minimum sealant is 6mm and there are many types of sealants depending on the usage and application.

Additionally, structural sealant should not be used for long term loads. Structural silicone sealant must be tested for compatibility with all materials to which it must adhere on a project-specific basis.

A compatibility test certificate for sealant should be provided to confirm the compatibility of sealant with all finishes and materials.

Considerations for fixing and hardware

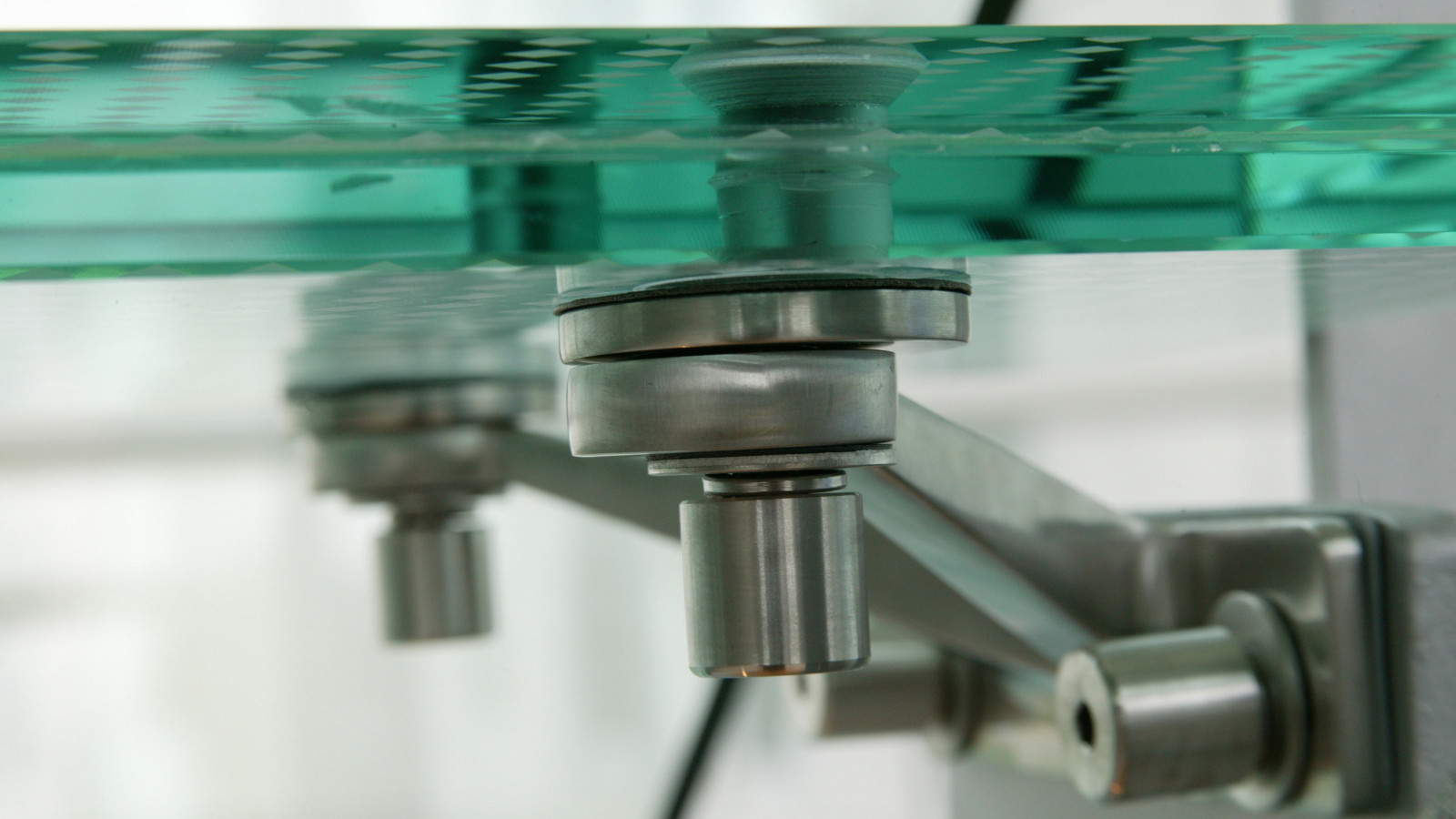

Fixing and hardware are two of the most important components in the glass design process. There is a variety of fixing and hardware options which are designed to provide a secure connection between the glass component and the support structure and to absorb forces when the glass flexes under load.

Countersunk fittings are one method that can be used to support glass. A countersunk hole is drilled through the glass panel to allow the secure installation of fixings or hardware. When loads are exerted onto the panel, they are transferred from the glass through the countersunk point fixings and into the support structure.

There is also a wide range of proprietary fixing systems that could be applied to secure the performance of the glass as a barrier. These include:

- Infill Frame or Sections (glass is wedged into the channel in a frame)

- Infill Mechanical Fittings (glass is fixed to metal cleats with countersunk fittings)

- Infill Clamp Fittings (glass is clamped by clamp fittings fixed to the frame)

- Infill Spider Fittings (spider connection system fitted to posts that allow for vertical and horizontal adjustment).

It is important to provide the glass designer with the point fixing relative movement due to differential deflection of the supporting points

In next month's blog post, I'll be discussing the structural glass maintenance, inspection and crack patterns.

Most Popular

Most Popular Popular Products

Popular Products