The benefits of choosing NZ-made

New Zealand manufacturers utilise the local workforce benefitting from NZ’s depth of skills to develop innovatively designed products for the local market. New Zealand has built a strong reputation for quality, sustainable values and honesty in local manufacturing. Additionally, the economic benefits are retained within the country and support local employment.

Allproof’s range of passive fire protection products are manufactured at its production facility on the North Shore of Auckland employing over 130 staff. Allproof’s intumescent material is produced in-house, then cut and assembled into a range of products. The cast-in fire collar range are moulded on site from 100% recycled materials using clean solar energy reducing the carbon footprint of innovative NZ made products.

NZ testing for total confidence

IANZ provides an NZ recognised accreditation system for laboratories to ensure product specifiers, installers and end users can have complete confidence in the testing, application and inspection of products tested at these facilities.

Allproof use independent local testing laboratories that are IANZ accredited with high levels credibility to ensure accurate and honest testing in their product range. All product testing is conducted with full compliance to AS1530.4 and AS4072.1.

Trusted NZ appraisals

A BRANZ Appraisal is a “robust, in-depth and independent evaluation of a building product or system to assess whether it is fit for purpose and meets Building Code performance requirements” — BRANZ. Allproof’s passive fire protection literature and product range has been BRANZ Appraised adding another level of credibility and trust to the testing process and results.

By obtaining an appraisal on product literature and testing Allproof display integrity and honesty to ensure that locally made and tested products live up to the high reputation and the expectations of NZ made.

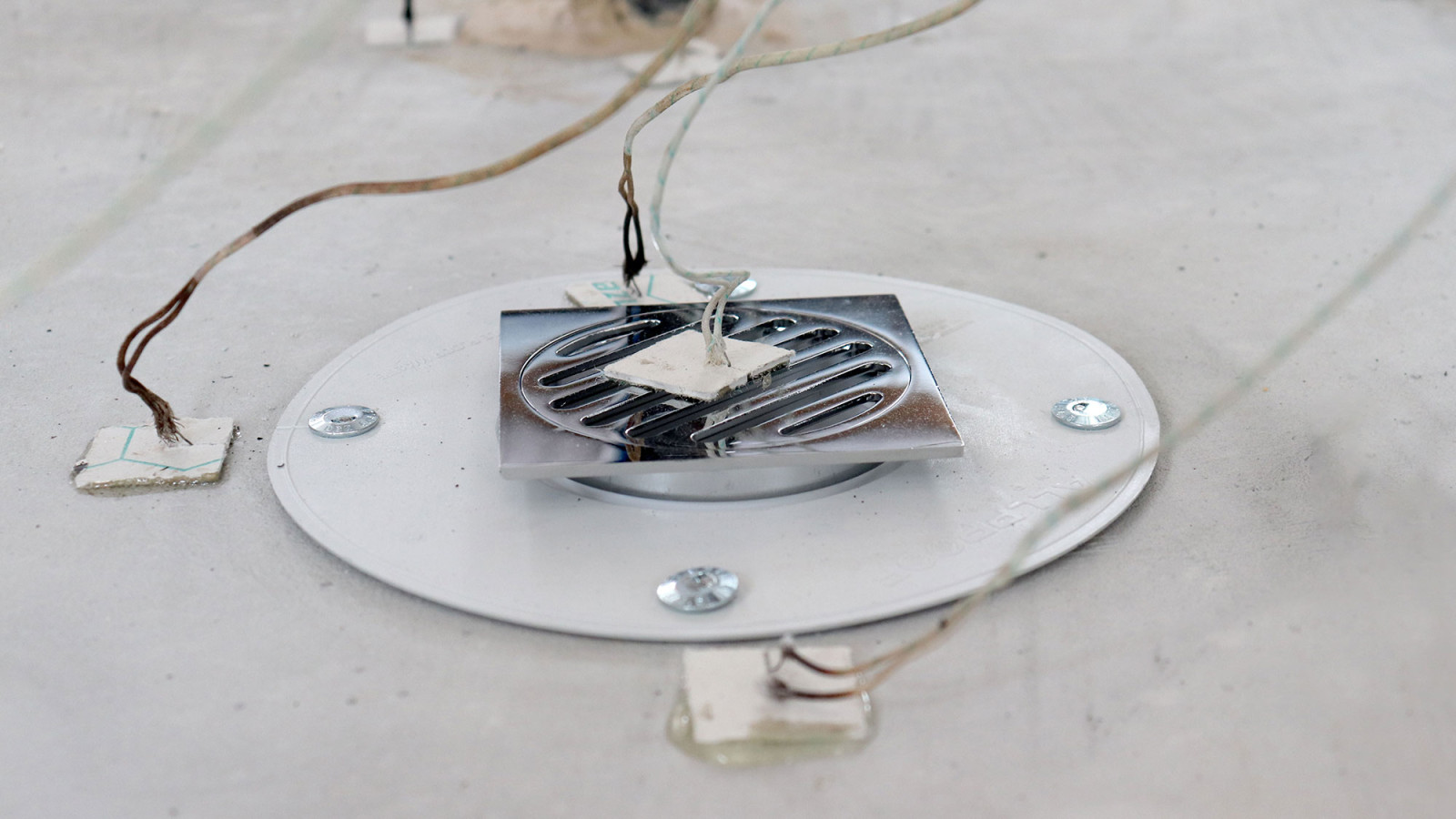

The above illustrates that Allproof goes to great lengths to ensure that product testing is conducted appropriately and meets every requirement in AS1530.4 and AS4072.1. Both standards state that when testing a floor waste a thermocouple is to be “fitted to the centre of the grating, unless in the opinion of the registered testing authority another position is likely to record a higher temperature, in which case the thermocouple may be offset from the centre of the grating”. Allproof’s floor waste solutions are tested using standard grates with the thermocouple positioned to record the highest temperature reading during the test.

Honesty and integrity are essential components to being NZ made. These are core values Allproof continually places at the forefront of all product development, testing and manufacturing enabling Allproof to build a strong trustworthy reputation over the past 37 years.

Most Popular

Most Popular Popular Products

Popular Products