The Problem

An often-encountered problem, especially when retro fitting insulation into an existing exterior wall from the inside, is how to provide a drainage and air plane behind the cladding. This is particularly relevant behind sheet cladding such as fibre cement board and profiled metal.

A built cavity system can be very difficult as the insulation will force the underlay to bulge back to the exterior cladding, with the potential for moisture to wick to the insulation. Very little control is possible. The problem is amplified as most BIB insulation will be compressed due to the loss of depth in space between the studs.

The Solution

Tyvek Metal is an ideal solution to assist with allowing an air and drainage space behind insulation blanket, especially when retro-fitting insulation from the interior to an existing cladding. It is also suitable for use against block and precast walls when lined internally, in this case helping to prevent the transfer of cold and damp to the interior lining.

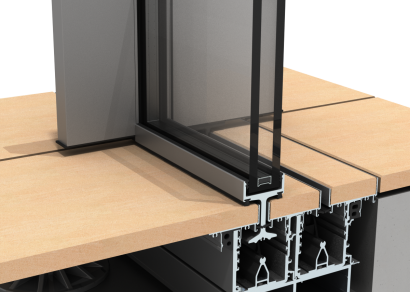

Tyvek metal consists of an 8mm three-dimensional welded plastic mesh adhered to Supro underlay. The weave of the plastic mesh allows for a 90% open ventilation and drainage plain, and assists in preventing moisture transfer. The Supro layer gives a strong bonded layer, aids with the insulation and vapour transfer, and will not transfer liquid moisture.

Benefits:

- 8mm mesh drainage mat provides a drainage and ventilation plane by separating the underlay from the cladding and masonry walls prior to lining

- High Moisture Vapour Transmission Rate allows buildings to dry out, helping reduce condensation

- Non kraft paper based, meaning it may be exposed to rainfall during installation without affecting durability or performance

- Functional layer of 175 microns (up to seven times the thickness of other synthetics) provides a robust, durable and UV resistant underlay to withstand job site conditions

- No shrinkage allows no maximum run length on installation

- 1.5mm wide roll with integrated tape layer to cover more area per sheet with less number of overlaps

- Suitable for use behind absorbent and non-absorbent wall cladding

Tyvek Metal is also widely used in roof applications.

- Understanding seam profiles such as the Euro Tray style when laid on ply and OSB sarking

- To provide moisture and ventilation plane

- As a combined separation layer and underlay in applications with the potential for condensation to form on the underside of the underlay. A typical application is in a south facing skillion roof in a frost prone area. This is made worse with the trend to dark colours.

Product News

Product News

Popular Products from Tyvek

Popular Products from Tyvek

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts