This new development in Ranui, West Auckland, features two multi-storey blocks, each with six units. The project involved the redevelopment of a site which brought together land from what were originally neighbouring stand-alone houses. When it came to building the foundation, ground condition challenges arose — which could have turned out very costly to resolve. StopDigging provided a groundscrew foundation solution that mitigated these issues and helped keep the project on track.

“Initially, the plan was for standard slab on grade for the whole build, but the engineers discovered some issues at the front of site that meant they needed to increase foundation capacity,” explains Warren Henton, StopDigging.

Two key issues were discovered — the ground conditions would require deeper foundations than slab on grade, and they needed to strengthen the ground at the front of the building to support specific point loads.

The engineers considered removing soil and reinforcing with concrete and steel to support the weight for the deeper foundation and point loads, but this would have added further costs and unnecessary complexity to the project. The developer turned to StopDigging to see if they could provide a groundscrew foundation solution for the project.

“The developer got hold of us and asked if our system could work on the site,” explains Warren. “We said, tell us what we need to support, and at what depth, and we will have a solution for you.”

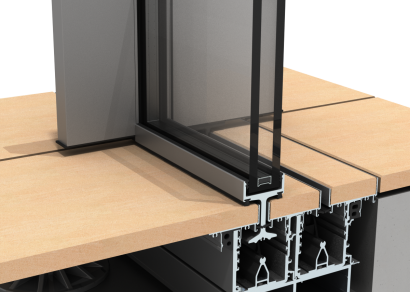

StopDigging’s foundation system uses groundscrew piling to efficiently mitigate poor ground conditions. It is a low impact, zero waste system that eliminates the need for extensive ground works, helping to save time and costs on site.

For projects where there is an in-ground beam as part of the slab on grade design or if there’s a perimeter ribraft beam, specifying StopDigging is a very straightforward process. “The engineer just determines what loading is required along that beam,” says Warren. “We then go on site and test the ground with an in-ground engineered static pile test — that determines what specific load we get out of each screw so we can determine how many screws are needed.” And for projects where point loading is an issue, StopDigging can create a solution by grouping screws tighter at key points to provide the additional support needed.

Specification is also aided by the system’s CodeMark certification which gives architects and engineers peace of mind that it will be accepted by councils. “The CodeMark certification certainly makes the consenting process and design process very simple,” says Warren. “We also have a full range of documentation that shows architects and engineers how the system works, and how to deal with it.”

On this project, the system was brand-new to the engineering team, but once StopDigging explained how it works, they quickly saw the benefits. “Working with StopDigging prevented them from drilling large holes and filling with concrete and steel, or using a ram pile method — two alternatives we’re looking to mitigate against,” says Warren.

The groundscrew foundation system was a time and cost-saver for the project. “It was basically a one-day install per unit for this project, spread across three days as they had three different areas in the build,” says Warren. “In total we installed 20 ground screws into a 3m embedment which was a one day exercise.” Once the StopDigging system was in, construction could continue on the multi-unit build — with no soil removal, no waste and no need for additional concrete and steel.

Ultimately the StopDigging groundscrew foundation system provided a smart solution for resolving ground conditions on site and resulted in savings in time, cost and complexity. And while this was the first time the engineers used StopDigging’s system, it certainly won’t be the last — they’ve already specified the groundscrew foundation system for future projects in the works.

Product News

Product News

Popular Products from StopDigging!

Popular Products from StopDigging!

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts