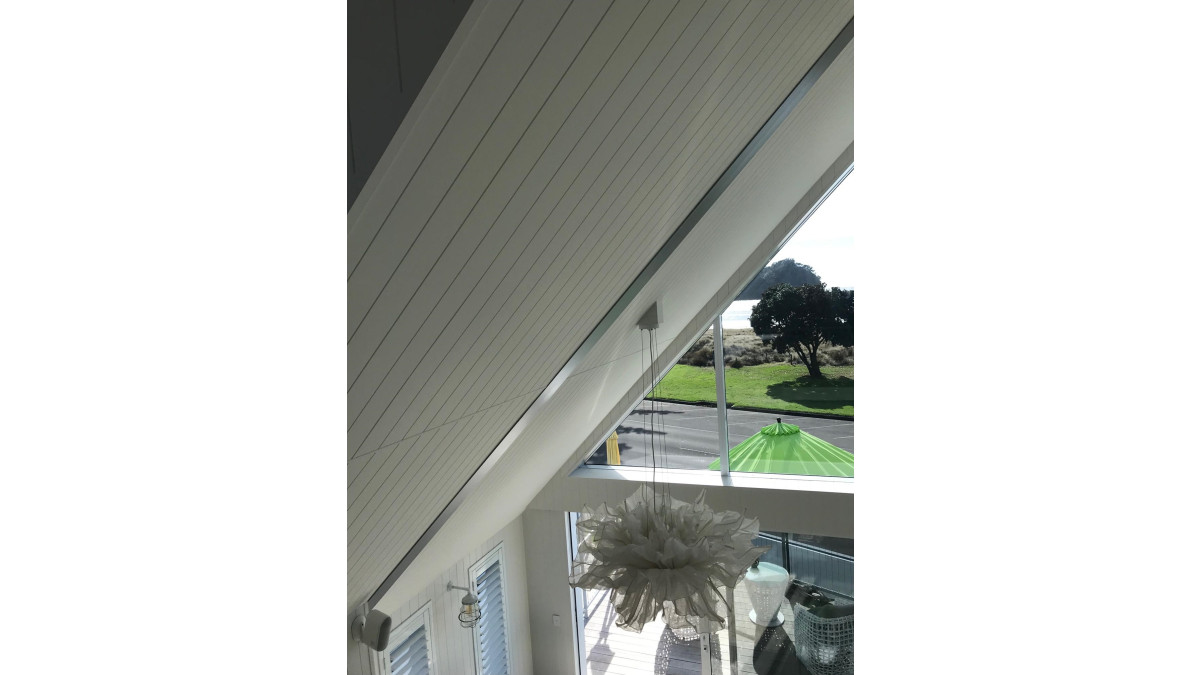

Plankwall V grooved building panels with neat fitting T and G edging continue to be recognised as a quality useful building product. The joins are concealed and if a nog is proud or the stud twisted, the problem is minimised with the panels inter-locked together.

Plankwall V grooved panels are available in 9mm and 12mm thickness, with lengths up to 3.8m. Fixed with pins and construction adhesive, the smooth MDF surface just needs the pin holes wiped with a filler, before painting.

The wind and earthquake BU’s of each panels is almost equivalent to designated bracing panels of plasterboard. In recent earthquake affected areas limited remedial work has been required. In contrast, plasterboard homes often require attention of powdering at joins, architraves and fixings, often with repainting required.

The added thickness of 12mm improves the already good thermal qualities of the 9mm. A Blenheim builder built his own home using Plankwall, and his neighbours' home with plasterboard. His home is 2 degrees warmer in winter. And cooler in summer.

Almost Finished is a factory applied UV coating of two coats white on the face, one clear on the back. Hermetically sealing the panels. This eliminates moisture and temperature induced movement, and speeds up job completion times too!

Plankwall “Plain Faced” Almost Finished is also gaining interest. This option has no grooves on the face but still has a tongue and groove edge. The UV coating is hard wearing, scratch resistant, unlikely to support mould growth, easily able to be wiped clean and offers impact resistance almost three times that of plasterboard.

Case Studies

Case Studies

Popular Products from Plankwall

Popular Products from Plankwall

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts