Plankwall's W Grooved panelling adds charm and interest to a home. Panels can be attached direct to the studs, or in an existing home can be fixed on top of the existing walls adding another layer of insulation.

How are Plankwall W Grooved panels made?

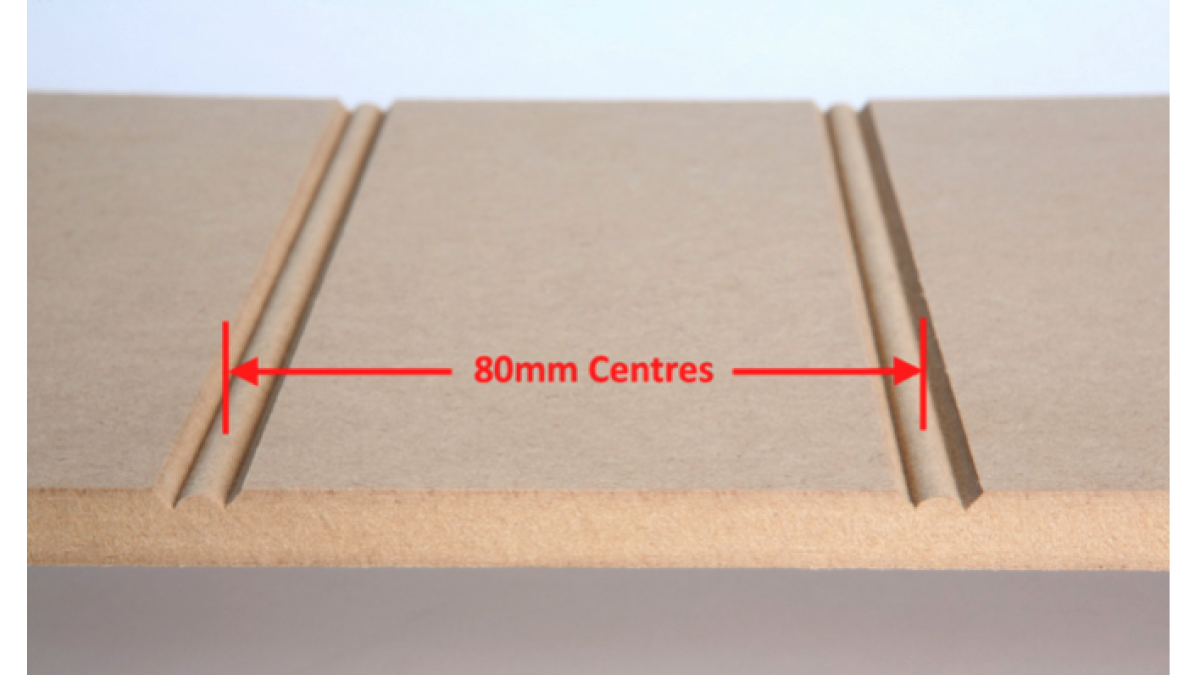

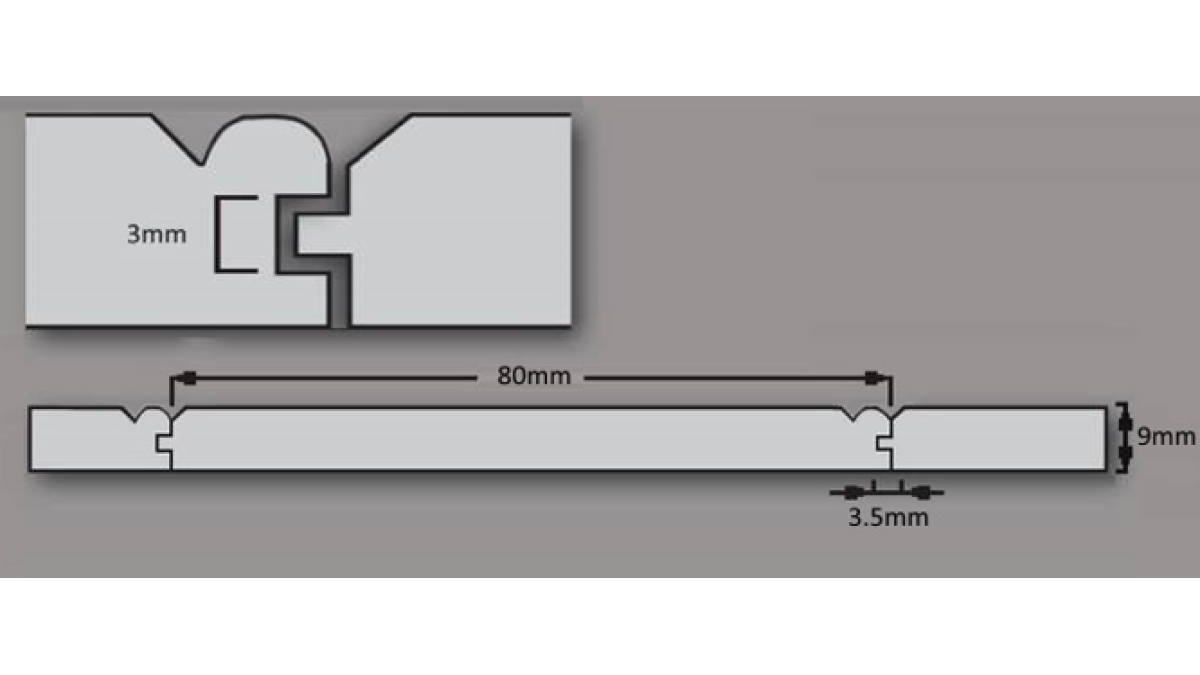

Plankwall building panels are machined on a two-monthly production cycle, in a climate positive, carbon neutral factory. Machining quality Nelson Pine E0 Standard MDF by using blades, compresses the fibre for a smooth W groove. The same process is used for Plankwall's V Groove panel option — eliminating the issue of roughened, groove surfaces which can occur when using router blades.

All Plankwall grooved profiles have T and G edges to conceal panel joins. A butt join will always be difficult to conceal and allow draughts to occur.

Panels sizes: 1200mm wide, 9mm thick, 2.44m and 2.76m long.

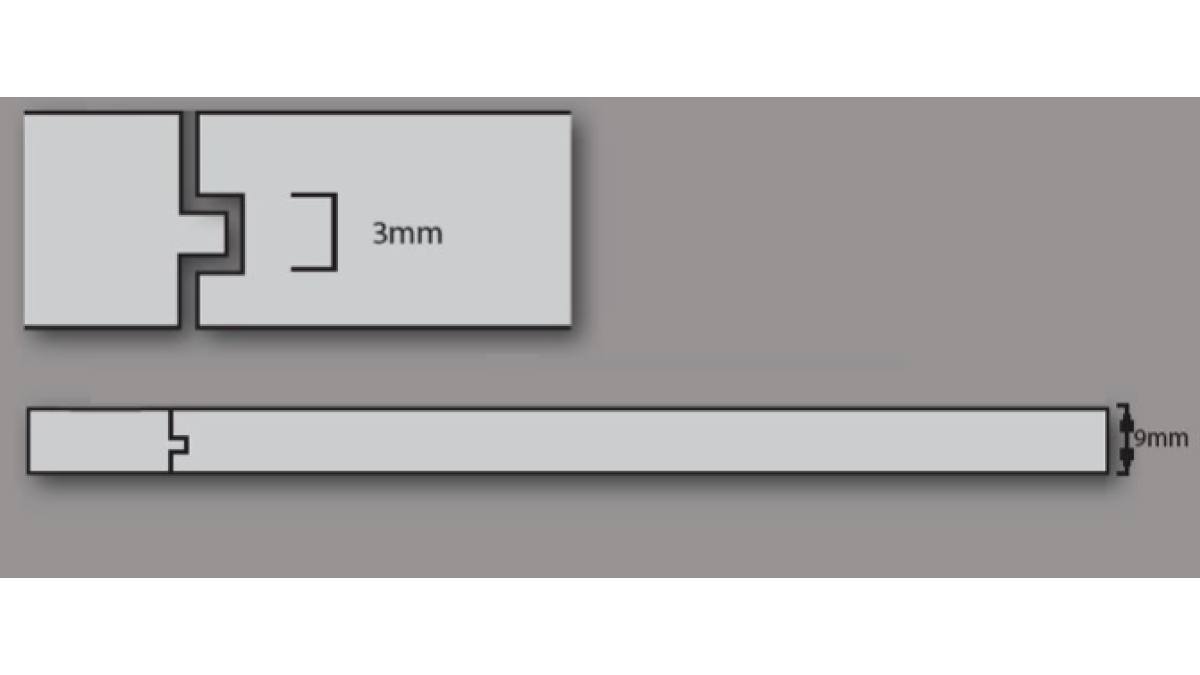

Combining W Grooved with Plankwall Plain Faced

On a project specified to dado height, Plankwall’s Plain Faced (also with a T and G edge) can be used above the W groove. With both panels being 9mm thick, this is an easy way to combine textures while avoiding the need for another subtrade.

Plankwall Plain Faced is available in an Almost Finished option, which is UV coated on both sides and hermetically sealed. This means the panels are not affected by changes in moisture levels. Joins will remain concealed with minimal panel movement.

Fixing Plankwall Panels

Plankwall exclusively use Nelson Pine Golden edge Standard E0 panels. Use of their PanelBrace system appraisal can be used as part of the bracing structure under BRANZ appraisal 779 so long as installed as per NPIL specifications and Installation Guidelines. This now includes the use of gunned finish nails or staples which speeds up installation and reduces the amount and size of filling required to finish.

For more information please contact [email protected] or 09 272 9990

Case Studies

Case Studies

Popular Products from Plankwall

Popular Products from Plankwall

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts