The challenge

One of New Zealand's leading architectural firms approached Nuralite with a unique problem. In order to refurbish an existing 30-year-old standing seam metal roof, they needed a solution. The roof sloped less than 1.3°, preventing a like-for-like replacement due to warranty limitations. As part of the refurbishment, the designer wanted to improve the roof's insulation levels without affecting the ceiling height. All while minimising disruption to tenants and staying within a cost-conscious budget. Quite the brief!

Nuralite's solution: Nuraply 3PM Warm Roof Overlay

Preparation:

Repairs were made to the existing standing seam metal tray roof, minor coatings were applied to the surface rust areas, and small sections such as skylights were replaced.

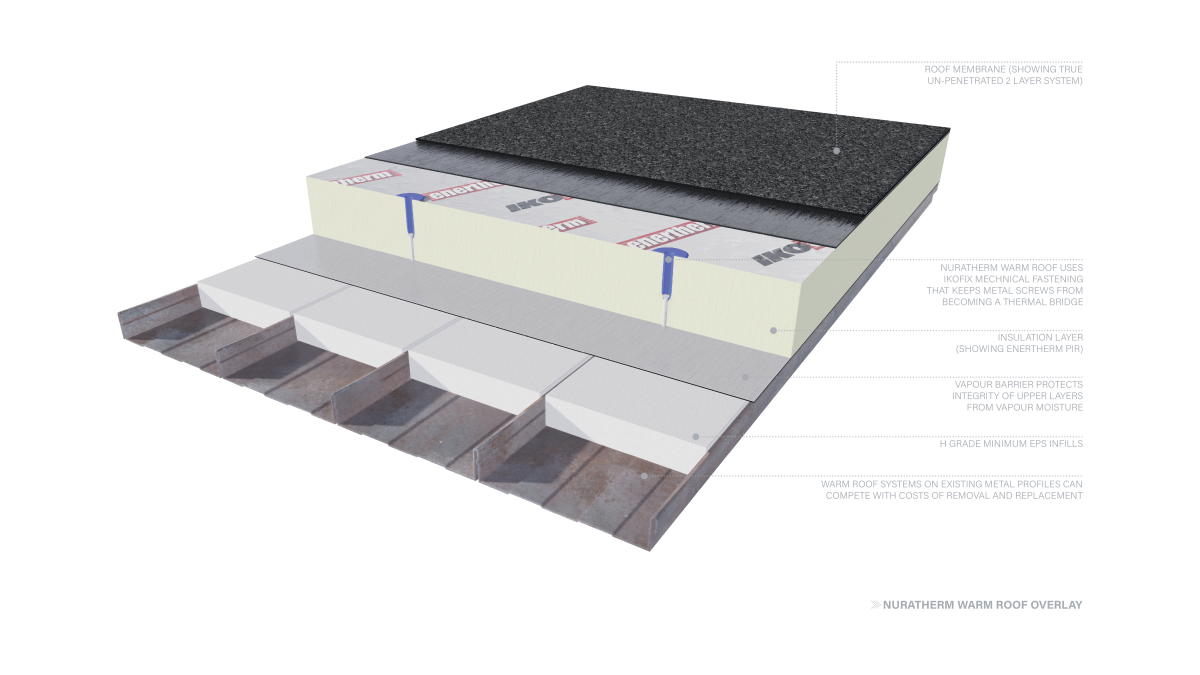

Insulation layer:

Recycled Nuralite PIR insulation boards were cut into strips and fitted within the tray sections of the existing metal, providing a monolithic, flat surface for the application of the Nuraply ALU vapor control layer. Subsequently, 100mm Nuratherm PIR insulation boards were installed over the entire roof area, providing a continuous, true construction R-Value of 5.

Waterproofing membrane:

The two-layer Nuraply 3PM membrane system was installed to provide long-lasting, robust waterproofing. The final selected membrane system's CodeMark Certificate allowed for the existing 1.3° slope, streamlining the consenting process.

Drawing upon their expertise as New Zealand's leading waterproofing exponents, Nuralite is proud to have devised a solution that comprehensively addressed the client's needs. Enhancing insulation, maintaining waterproofing integrity during refurbishment, and adhering to a carefully managed budget were key elements that made this project a resounding success.

New Products

New Products

Popular Products from Nuralite

Popular Products from Nuralite

Posts by Shane Clarke

Posts by Shane Clarke Most Popular

Most Popular