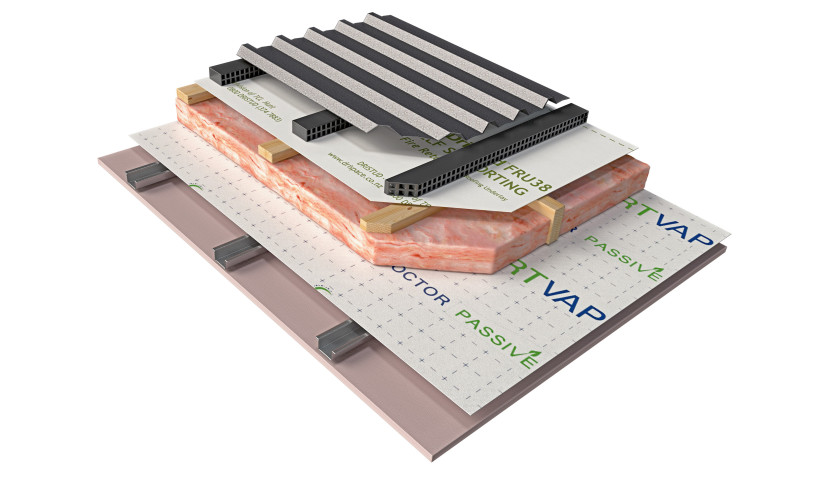

Water ingress is one of the biggest challenges the facade market has at present. Although rigid air barrier board can be left exposed with the joints filled with tape or sealant, the joints are still a weak point in the design. Proctor Wraptite SA not only offers the benefits of breathability but also airtightness and water tightness. By using Proctor Wraptite SA, installers seal the whole envelope and negate the dressing required for steel frames.

An example of this is the beautiful Empire Theatre in Toowoomba, regional Queensland which was built in 1933 at the height of the art deco period. Unlike many of its contemporaries, the Toowoomba Empire Theatre still stands today, proudly displaying many of the faithfully restored art deco features for which the heritage listed building is renowned and much admired for.

In 1996 the Empire Theatre underwent an award-winning restoration by Hassall Architects and now boasts of being one of the largest regional performing art centres in Australia. However, as with the restoration of many older buildings, the Empire Theatre was not without its own foibles, amongst them notorious building leaks.

In 2014 the theatre underwent additional refurbishments including the repair of building leaks caused by a failing facade system. With minimum disruption, the Proctor Wraptite SA vapour permeable membrane was applied directly over the existing 1996 fibre-cement cladding facade to prevent further moisture ingress and to still allow for walls to dry out and stay dry. The building was re-clad with the Proctor Wraptite SA providing a second layer of protection behind the rainscreen.

The Wraptite membrane not only provides a simple and robust solution to the challenges of water tightness but also reduces air leakage which can significantly impact the energy performance of the structure.

Product News

Product News

Popular Products from DriSpace

Popular Products from DriSpace

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts