Flooring system

Is the flooring a sheet or vinyl finish? Or is it concrete or epoxy?

If the flooring is a vinyl system, then the outlet will have to be a clamping style product. This ensures the edge of the sheet has a flange to adhere to, and most importantly a clamping ring to secure the edge and prevent premature wearing or release of this connection.

An epoxy flooring system will require a good, solid edge to finish against, as often they terminate as a silicone join between flooring and outlet.

Point or channel drain?

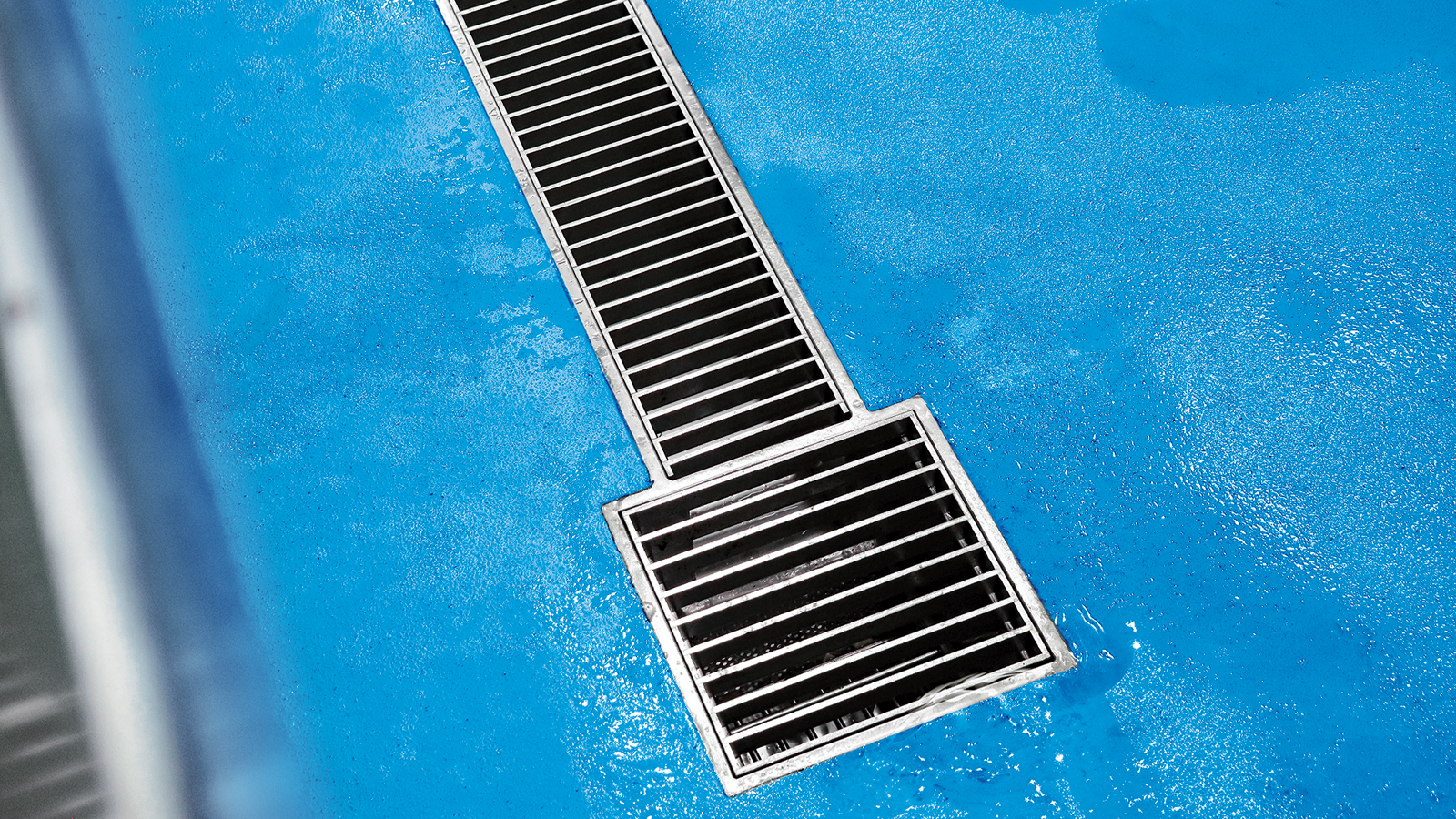

There are two styles of outlet: point or channel. Both have their place and sit at points of efficiency, serviceable area and construction.

A point drain is economical to set up, they can be installed as required and piped out below the slab. They can, however, sometimes only service a very local area and demand. The outlet will get installed and then the flooring screeded to create falls to the outlet. This will involve a lot of screed build up if the area to be serviced is large.

A channel drain allows one outlet to service a larger area by providing the fall in the base of the channel and allowing the flooring to have a more level plane, while still providing an easy track for water and solids to be directed toward the outlet and strainer internally. These are normally cast into a rebate in the slab, allowing the channel to be set to just the right height, minimising additional screeding. Cast in tabs on channels allow for tying the product in and preventing floating at time of pour.

Strainers or sumps?

Most kitchen situations will require a strainer basket to be added to collect solids before they enter the SS line. Generally a double strainer is detailed, one fixed and the other removable. The removable basket will be the primary collector and the fixed one is there to make the outlet tamper proof and retain its design properties should the primary be removed. Sometimes these strainers can have differing size perforations to collect larger items first, and smaller items flow to the secondary strainer. Some systems will also allow a certain size solid to pass through as there will be an allowance further down the line to manage this waste, such as at a meat rendering plant for example.

Sumps can be added to a channel drain, or offered at a point drain to allow a larger area for these solids to collect and reduce premature blockages whilst in use.

Allproof supplies a range of off the shelf, and customisable solutions for commercial kitchens. The faithful Vinylrite or Storm Series point outlet with double strainer, VCC clamping channels and MC series modular channels suited to epoxy flooring are all stock items.

The design team can also work with you to customise the system to any length and installation demand. Often the channels supplied to a project can exceed 250 L/M, all manufactured locally allowing for shorter lead times and on site support. So reach out to the local experts for direction on your next project.

Most Popular

Most Popular Popular Products

Popular Products