Timber mid-rise and medium-density housing (MDH) have gained popularity in recent years. There are some major benefits, including land use efficiency, affordability, and the potential to foster a sense of community.

The growth in mid-rise and MDH brings attention to the inter-tenancy floors which separate the units above and below. Guy Marriage, senior lecturer from Victoria University of Wellington states in his book — MEDIUM, “the number one concern of many residents in existing MDH developments around New Zealand is noise”, and “Inter-tenancy floors are primarily concerned with direct impact sound.”

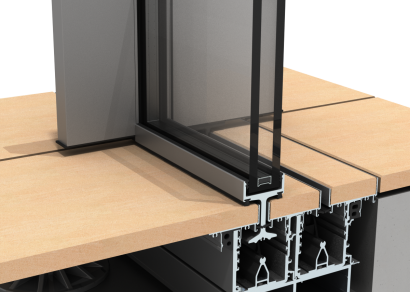

When it comes to high-density townhouse and apartment living, we do not want to sacrifice acoustic comfort and excellent privacy control. To meet the building code and requirements for acoustic control, building material suppliers provide flooring systems using different material and installation techniques to achieve this.

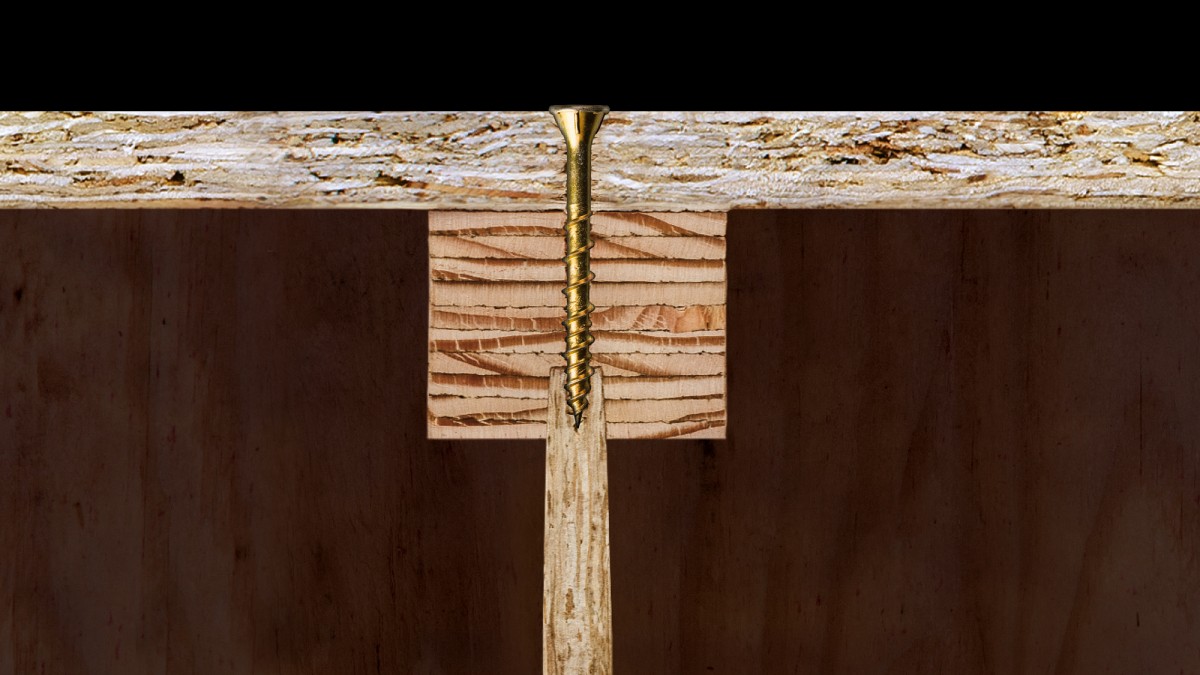

One of the common issues is squeaky floors in timber buildings. Squeaks happen when a house settles, the sub flooring dries, and then it expands. This expansion can cause the nails to pull up creating room for the flooring sheet to move upon temporary load such as occupants walking on it. This can also cause the sheet flooring to rub against each other, or against the subfloor.

Screw fixing is generally considered a more durable and long-lasting solution compared to some other fastening methods to secure floorboards, subfloors, or other structural elements when it comes to preventing squeaky floors. Due to the natural expansion and contraction of wood, temperature changes, and general wear and tear, screws are less likely to loosen over time, helping to maintain the integrity of the floor and preventing squeaks.

Benefits of screw fixing include:

- Stability and durability: Screw fixing provides a secure and stable connection between the flooring material and the subfloor. This helps prevent movement, shifting, or creaking of the floor, enhancing its overall durability and longevity.

- Reduced noise and creaking: The screws grip the wood more effectively and hold the parts in place, minimising any shifting or flexing that might lead to noise over time. Properly screw-fixed flooring is less likely to produce creaking or noise when walked upon.

- Minimised gaps and movement: Screw fixing helps minimise gaps between floorboards or joists, preventing them from separating over time. This reduces the movement of floorboards or subfloors, which can be a common cause of squeaks in a floor system.

Simpson Strong-Tie’s Quik Drive System is the industry standard for flooring tools, which offers ergonomic upright collated screw installation. A range of collated screws can be used with a variety of flooring materials, including plywood, particleboard, OSB, hardwood, engineered wood and cement sheet.

The Quik Drive PRO300 system accepts 8-12 gauge screws with a range of lengths from 40-75mm. This means it can handle all the main applications where builders commonly use their Quik Drive tools including flooring and underlay.

No more squeaky floors — Quik Drive screw fixing reduces the risk of a squeaky floor and contributes to acoustic solutions for inter-tenancy flooring systems.

References:

- Marriage, G. (2022) Medium. Chapter 8, Inter-tenancy Floors.

- Build Magazine, issue 193, Inter-tenancy floors in MDH

Product News

Product News

Popular Products from Simpson Strong-Tie

Popular Products from Simpson Strong-Tie

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts